A high-pressure turbine rotor centering device for an aero-engine and its application method

A technology of aero-engines and high-pressure turbines, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as inability to ensure concentricity, large measurement errors, etc., to improve the accuracy and effectiveness of axial clearance measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

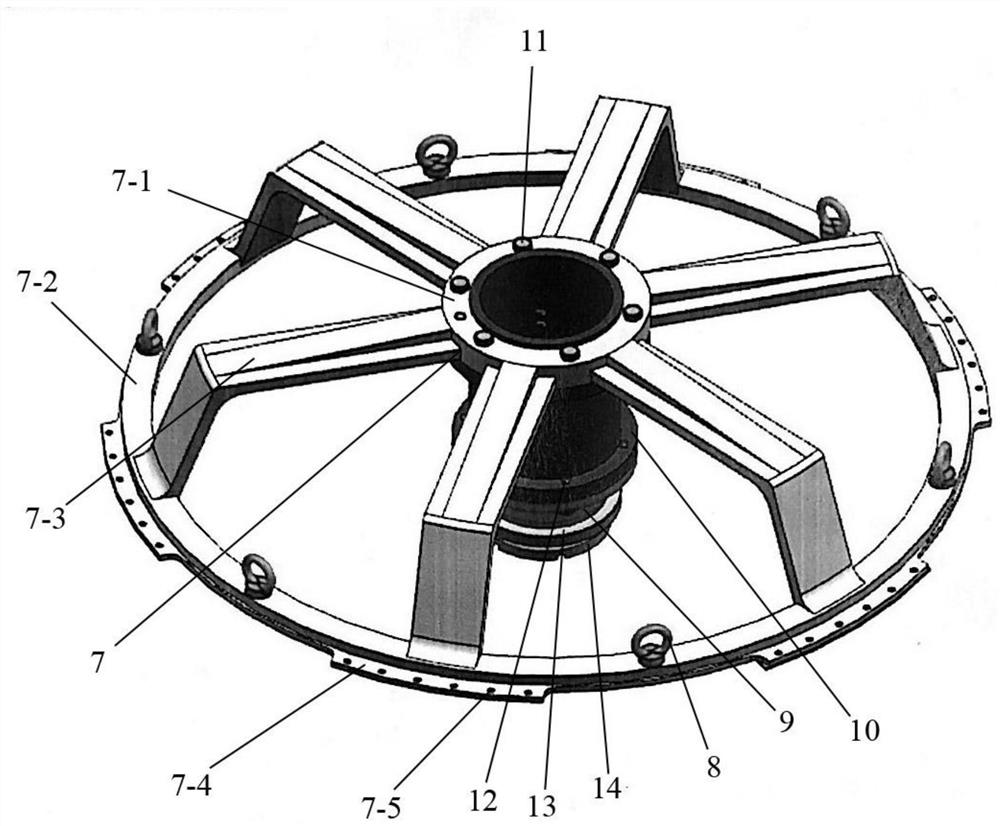

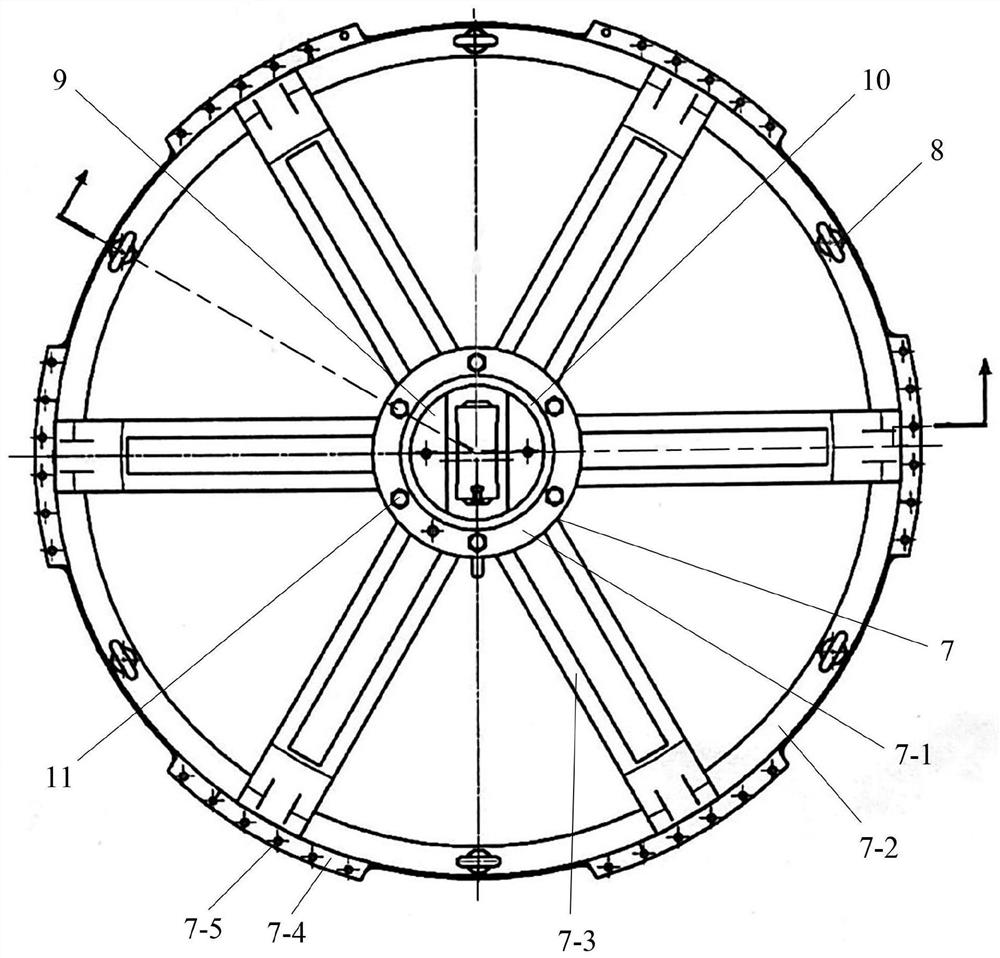

[0029] The purpose of the present invention is to provide a high-pressure turbine rotor centering device for an aero-engine and its use method, which can simultaneously realize the centering of the high-pressure turbine rotor and the hoisting of the low-pressure turbine assembly during the false measurement process, thereby ensuring that the high-pressure turbine rotor It is in a concentric state with the low-pressure turbine assembly, improving the accuracy and effectiveness of measuring the axial gap between the high-pressure turbine rotor and the low-pressure turbine primary guider.

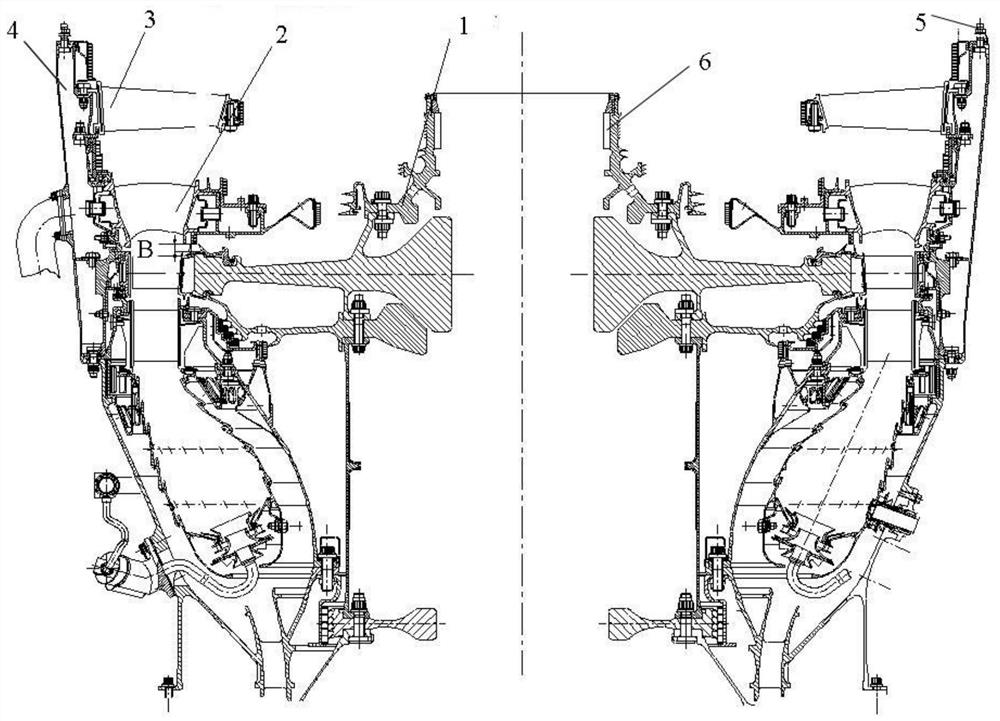

[0030] Such as figure 1 Shown is a schematic diagram of the structure of the aero-engine. Wherein, the aero-engine comprises a high-pressure turbine rotor 1 and a low-pressure turbine assembly, and the low-pressure turbine assembly includes a low-pressure turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com