Secondary metal smelting furnace and smelting device thereof

A technology for recycling metal and smelting furnaces, applied in furnaces, charge materials, crucible furnaces, etc., can solve the problems of increasing the burden of environmental protection, waste of resources, polluting the environment, etc., and achieve the effect of stable metal smelting process and excellent smelting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

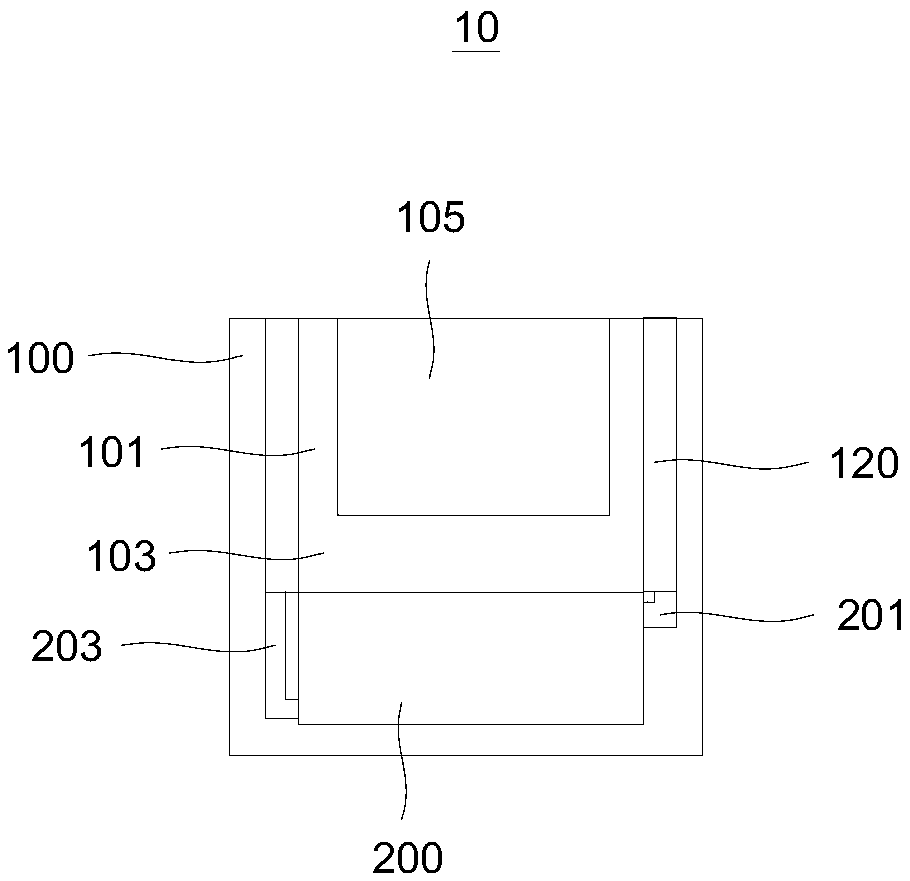

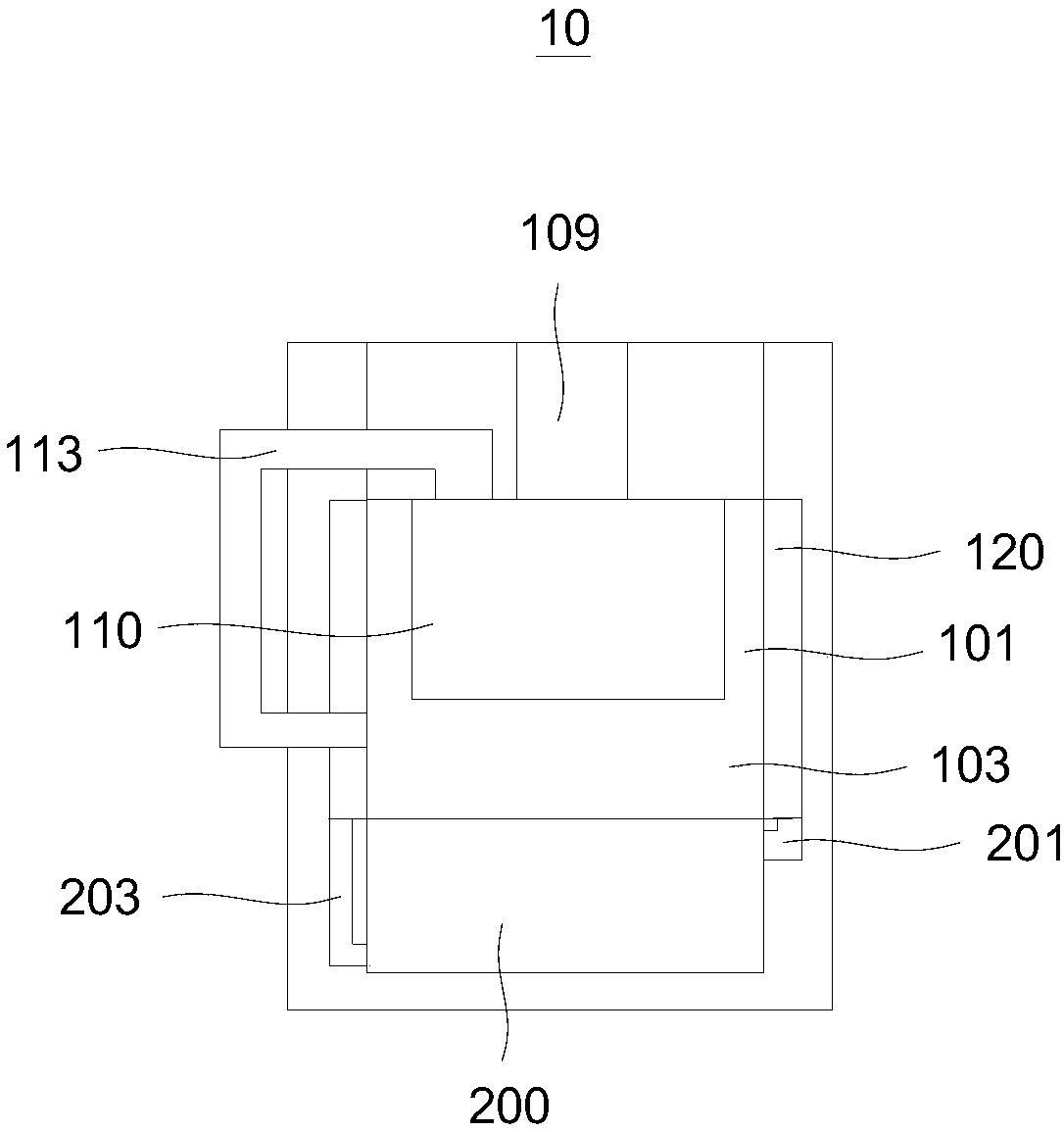

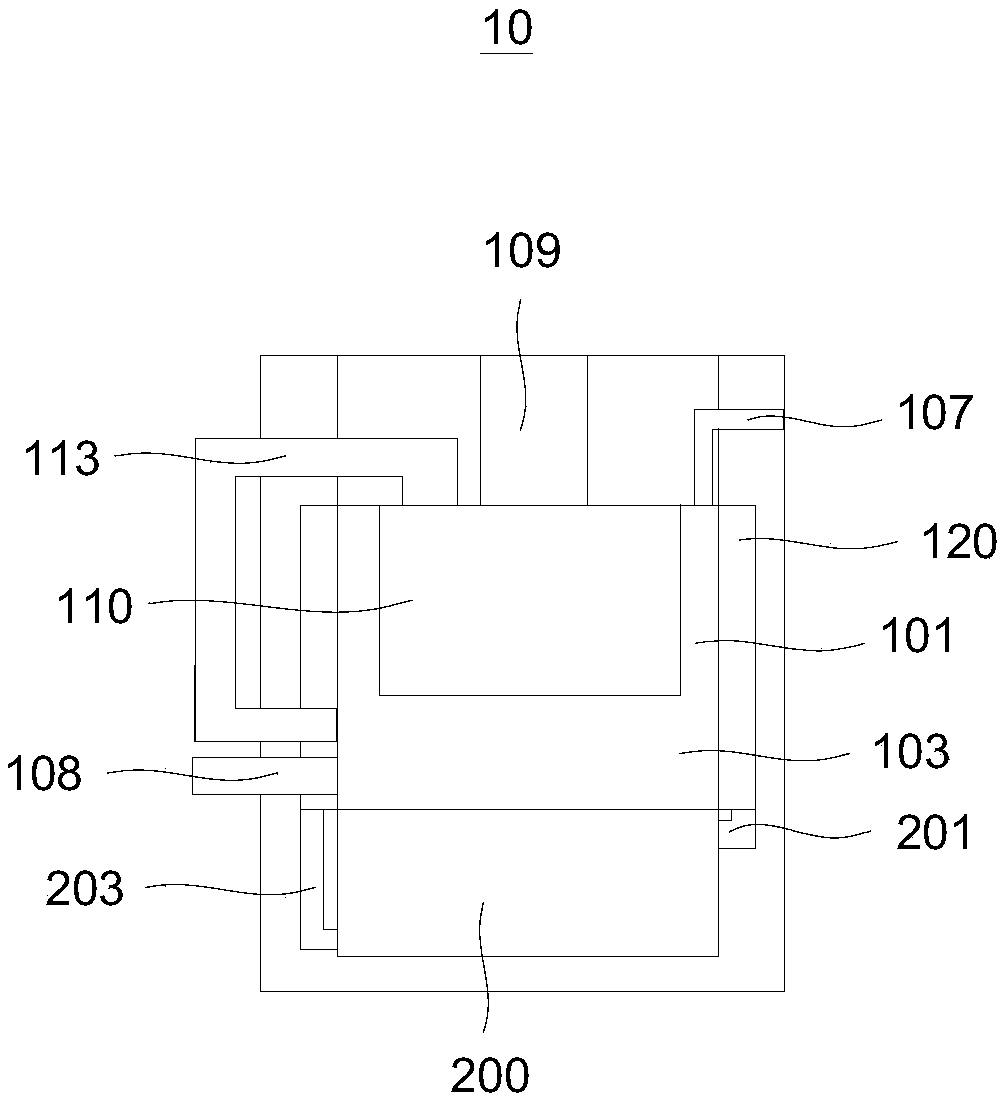

[0039] Please refer to the attached Figure 1~2 , the embodiment of the present invention provides a secondary metal melting furnace 10, which can effectively improve the utilization rate of fuel. The melting furnace uses most of the heat generated by the fuel in the combustion chamber for metal melting, and keeps the combustion chamber away from the melting crucible 110— The heat that is easy to lose from the side is stored and used for heat preservation of the melting crucible 110, so that the heat of the melting crucible 110 can be more stable and durable during the melting process, so as to improve the melting efficiency of metals.

[0040] Specifically, the recycled metal smelting furnace 10 includes a furnace body 100, a melting crucible 110, a heat exchange pipe 120, an insulated water tank 200, a fuel delivery pipe 108, a first liquid delivery pipe 201, a second liquid delivery pipe 203, a first waste gas Delivery pipe 113 and material feed pipe 109.

[0041] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com