Gear meshing mark detection method

A detection method and imprint technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low measurement efficiency and large measurement error, and achieve the effects of improving accuracy, good consistency, and facilitating data accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The method of the present invention is used for the detection of the meshing marks of the spiral bevel gear of the central gear box of the aero-engine:

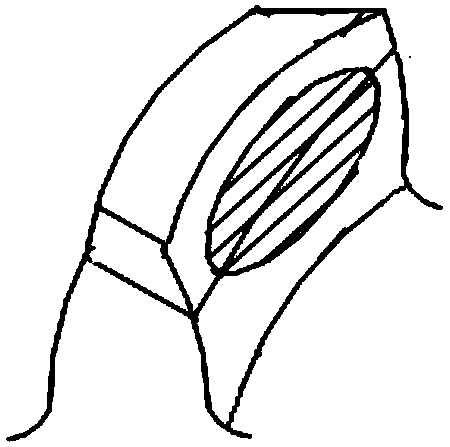

[0034] Step 1, using CAXA drawing software to survey and map the tooth surface shape profiles of the working surface and the starting surface of the central gearbox spiral bevel gear respectively, and use the CAXA drawing software to draw the surveying and mapping tooth surface shape profiles;

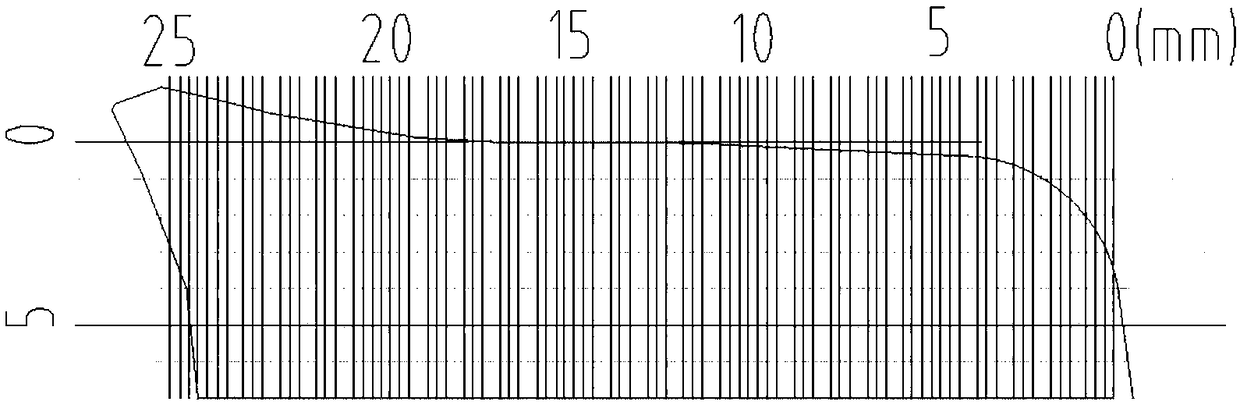

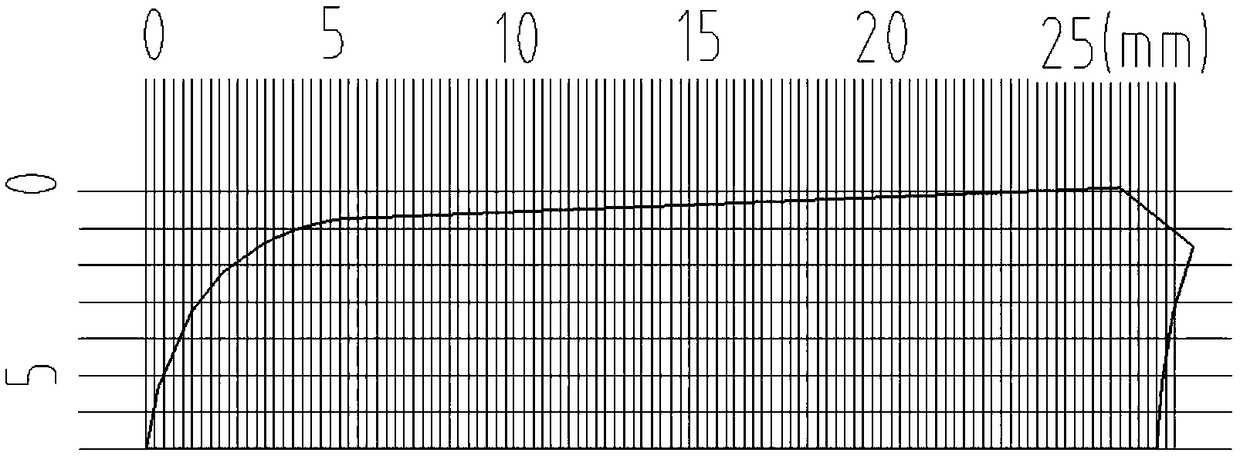

[0035] Step 2: Use CAXA drawing software to draw a coordinate ruler on the corresponding parts of the tooth surface profile drawn in step 1. The accuracy of the coordinate ruler is 0.25mm, and make a colored impression measurement card, as shown in figure 2 , image 3 As shown; print out the colored imprint measurement card, the printing ratio is 1:1; use transparent PET plastic film to print the colored imprint measurement card.

[0036] Step 3, use the coloring mark measuring card printed in step 2 to measure the dimensions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com