Measuring Method of Internal Temperature of Optical Components in Ring Polishing

A technology of optical components and internal temperature, applied in the parts of thermometers, thermometers and thermometers with directly sensitive electrical/magnetic components, etc., can solve the problem that the temperature distribution of optical components cannot be accurately obtained, and achieve a simple measurement process. Convenience, deterministic control, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] The method for measuring the internal temperature of the optical element in the ring polishing process of the present invention, the specific steps are as follows,

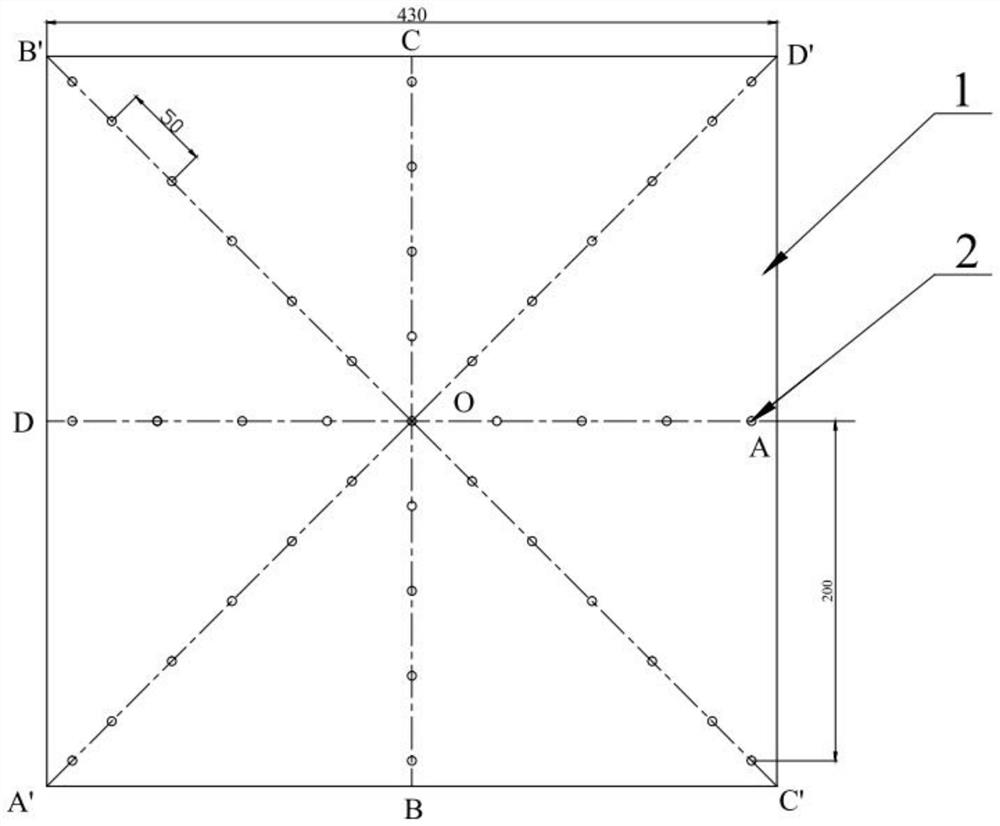

[0016] Step 1: A plurality of blind holes are drilled on the temperature collecting body 1 of the optical element as the temperature collecting hole 2, and the plurality of temperature collecting holes 2 are uniformly arranged in a concentric circular array with the center point of the temperature collecting body 1 of the optical element as the center of the circle. At the same time, the temperature collection holes 2 are also distributed along multiple radii of the concentric ring array; except the temperature collection hole 2 on the center of the circle, the temperature collection holes 2 located on the same radius of the concentric ring array form a group. The temperature collection holes 2 within the group have the same depth, and the two groups of temperature collection holes 2 located on the same diam...

specific Embodiment approach 2

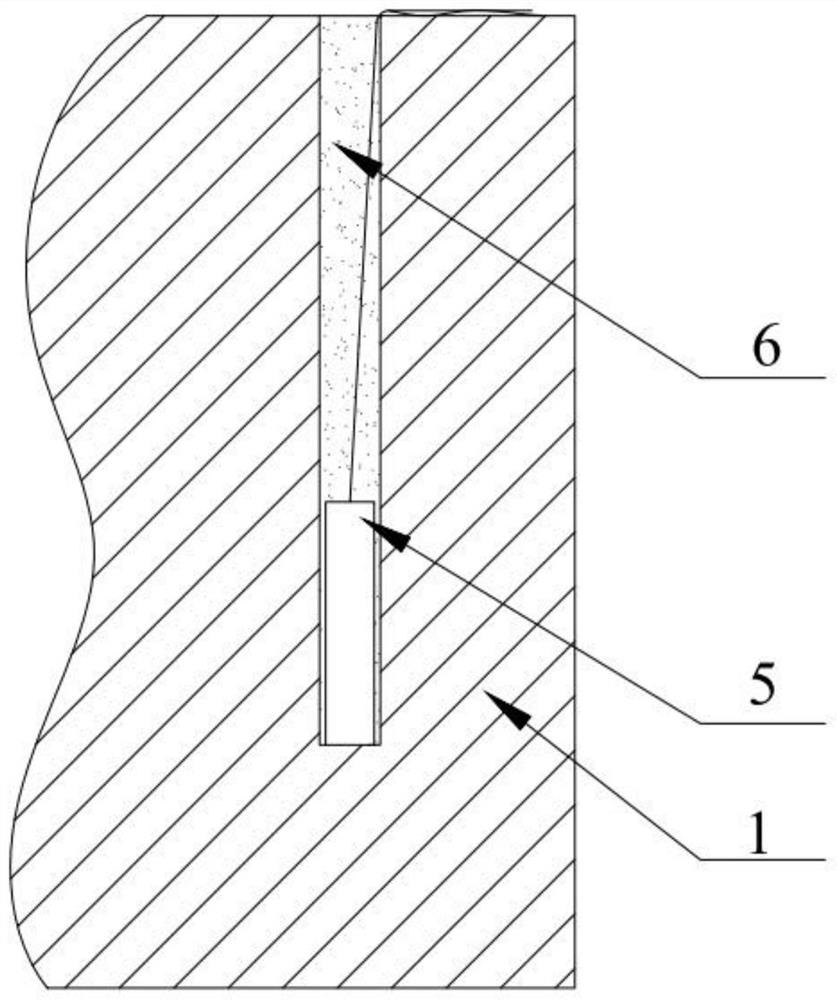

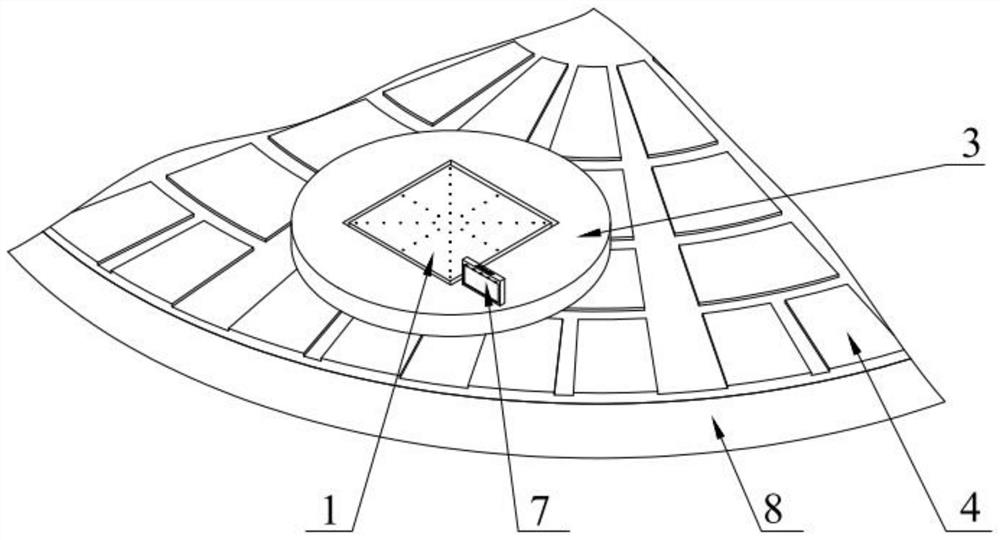

[0023] The difference between the second embodiment and the first embodiment is that in the second step, the temperature acquisition device is used to collect the temperature value at the bottom of each temperature acquisition hole 2: as figure 2 with image 3 as shown,

[0024] The temperature acquisition device includes a plurality of temperature sensors 5 and a recorder 7; the number of temperature sensors 5 is equal to the number of temperature acquisition holes 2;

[0025] Insert the measurement ends of multiple temperature sensors 5 into multiple temperature collection holes 2 respectively, and make the measurement ends contact the bottom surface of temperature collection holes 2;

[0026] Fill the heat insulating material 6 in the temperature collection hole 2, so that the measuring end of the temperature sensor 5 is fixed in the temperature collection hole 2;

[0027] The recorder 7 is fixed on the retaining ring 3 for receiving the temperature signals collected by ...

specific Embodiment approach 3

[0029] The difference between the third embodiment and the first or second embodiment is that, as figure 1 As shown, the cross section of the optical element temperature collecting body 1 is square or circular.

[0030] The square has a side length of 430 mm and a thickness of 80 mm.

[0031] On the basis that the cross-section of the temperature collecting body 1 of the optical element is square, the eight radii of the concentric rings respectively fall on the two vertical midlines and the two diagonal lines of the temperature collecting body 1 of the optical element.

[0032] Such as figure 1 As shown, the temperature collection hole 2 is divided into multiple groups, wherein the midpoint O on the upper surface of the temperature collection body 1 of the optical element is used as the dividing point, and the two vertical midlines and two diagonal lines are divided into eight lines, namely OA and OB. , OC, OD, OA', OB', OC', OD', the broken lines formed by each half of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com