Clamp device for automobile ABS brake valve

A fixture device and brake valve technology, applied in the direction of measuring devices, vehicle testing, instruments, etc., can solve the problems of reducing the processing efficiency of the brake valve, the inability to rotate the brake valve, complex structure, etc., and achieve simple structure, easy processing, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

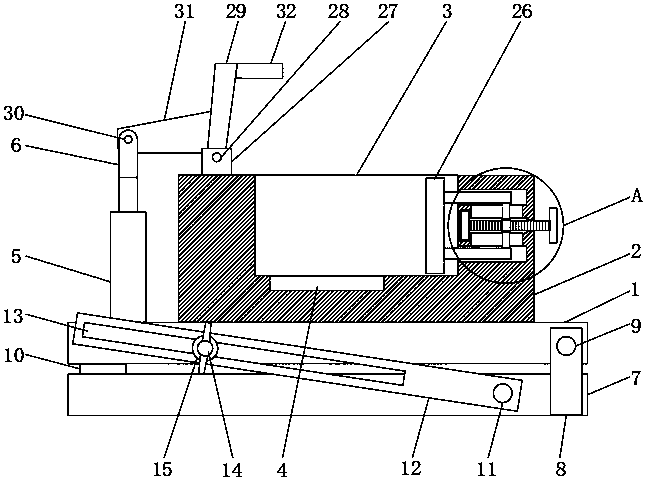

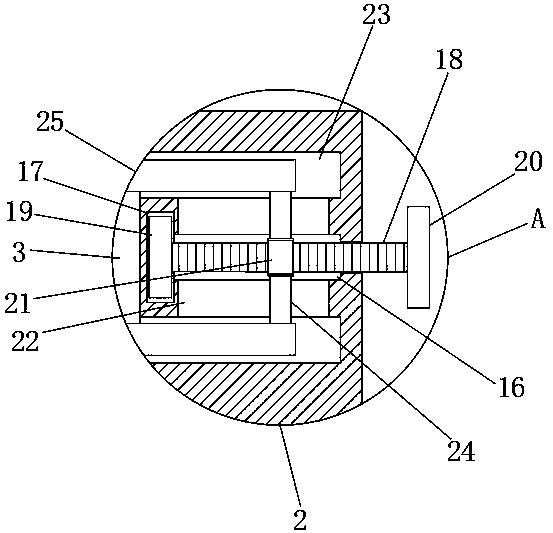

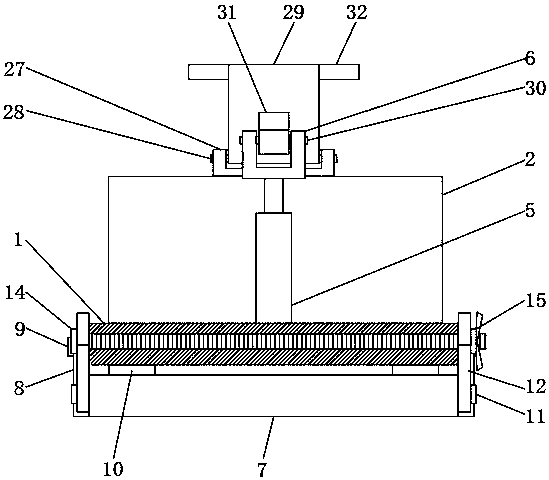

[0025] refer to Figure 1-3 , a kind of automobile ABS brake valve clamping device, comprises base plate 1, and the lower end of base plate 1 is provided with rotating supporting mechanism, and rotating supporting mechanism comprises the base 7 that is arranged on the lower end of base plate 1, and is all fixedly connected on the side walls of both sides of base plate 7 Fixed plate 8, fixed plate 8 is connected on the side wall of base plate 1 through the rotation of first rotating shaft 9, and base plate 1 can rotate around the first rotating shaft 9 on the fixed plate 8, and base plate 1 is fixed on the side wall of the lower end of one end away from fixed plate 8 Two mutually symmetrical support blocks 10 are connected, and the two support blocks 10 are both against the side walls of the base 7, so that the bottom plate 1 is more stable.

[0026] Wherein, the sidewalls on both sides of the base 7 are connected to the limiting plate 12 through the second rotating shaft 11, t...

Embodiment 2

[0031] refer to Figure 4-5 , the difference between this embodiment and Embodiment 1 is that a first rubber pad 33 is fixedly connected to the side wall of the clamping block 26, and a first rubber pad 33 is fixedly connected to the side walls of the first clamping plate 29 and the second clamping plate 32. There is a second rubber pad 34, and the side walls of the first rubber pad 33 and the second rubber pad 34 are provided with protrusions, which can prevent damage to the brake valve and play a certain anti-skid effect when clamping and fixing the brake valve. So that the brake valve can be clamped more securely and firmly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com