Visual double-sided detecting device for tobacco leaf with negative pressure, and detecting method thereof

A detection equipment and visual detection technology, applied in measuring devices, testing plant materials, material analysis through optical means, etc., can solve the problems of poor recognition effect of mildewed tobacco leaves and low-grade tobacco leaves, and achieve the effect of improving the recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

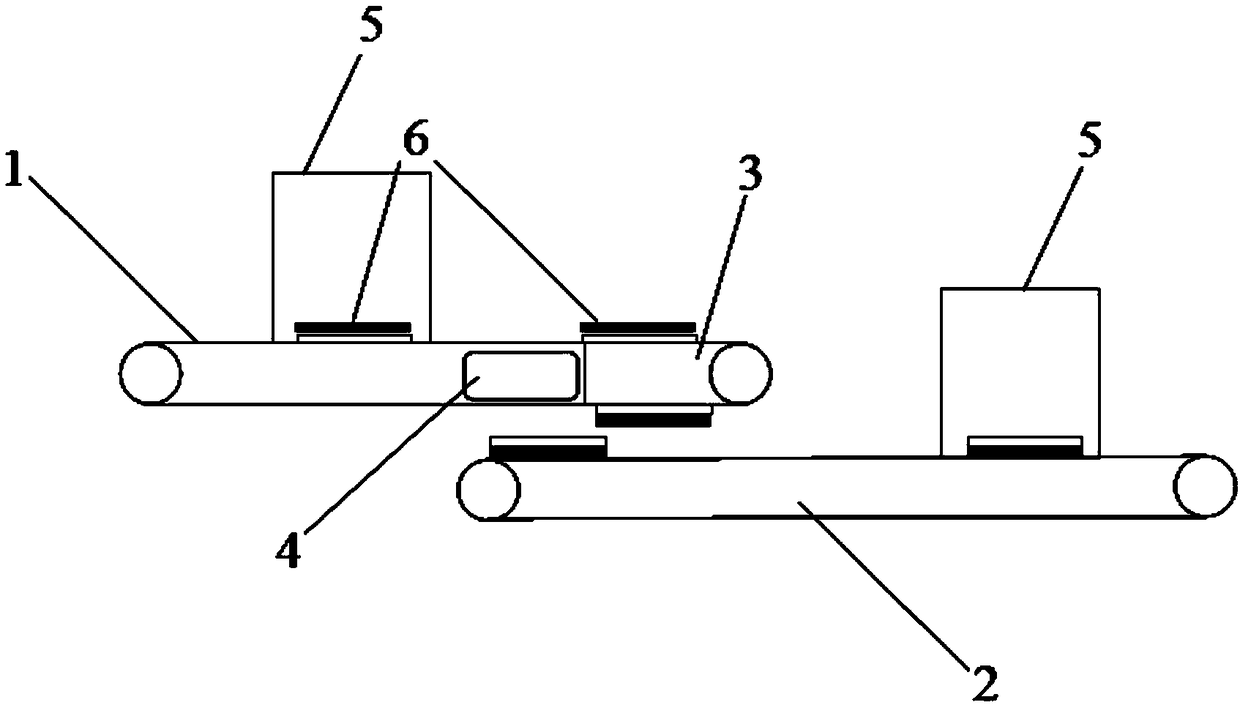

[0024] like figure 1 , 2 As shown in and 4, the present invention provides a negative pressure tobacco leaf visual double-sided detection device, including a negative pressure perforated conveyor belt 1, a second conveyor belt 2, a negative pressure chamber 3, a negative pressure fan 4 and a visual detection device 5. figure 1 The first side of the middle tobacco leaf 6 is represented by a black part, and the second side is represented by a white part.

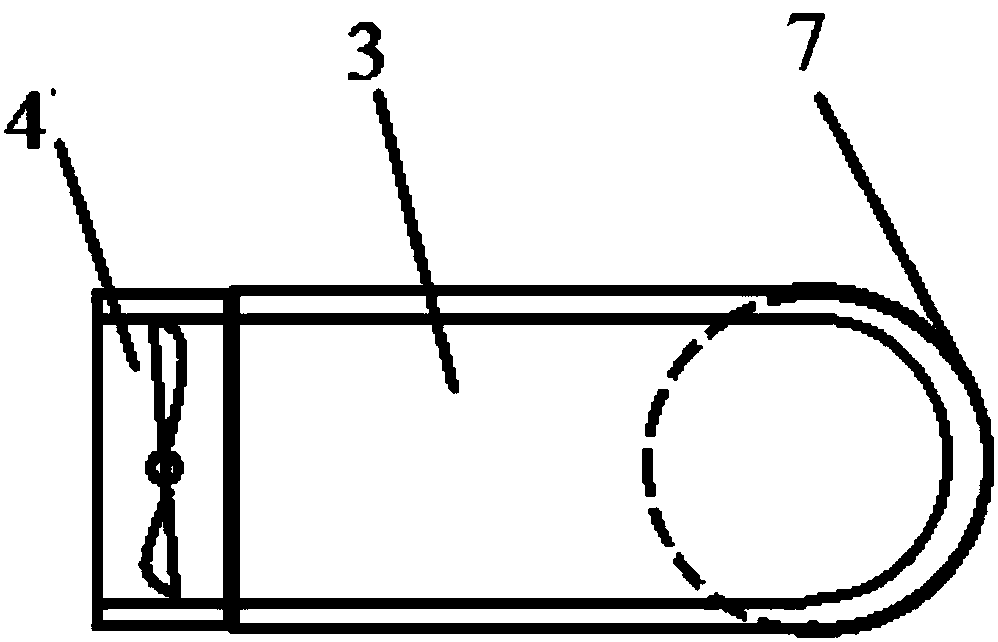

[0025] The negative pressure perforated conveyor belt 1 includes a conveying roller 7 and a perforated belt 8 wound on the conveying roller 7, and the surface of the perforated belt 8 is uniformly provided with a number of ventilation holes. The negative pressure chamber 3 is arranged on the inside of the discharge end of the negative pressure perforated conveyor belt 1, and the negative pressure fan 4 is installed on the air outlet of the negative pressure chamber 3 to generate negative pressure. The surface of the pressure...

Embodiment 2

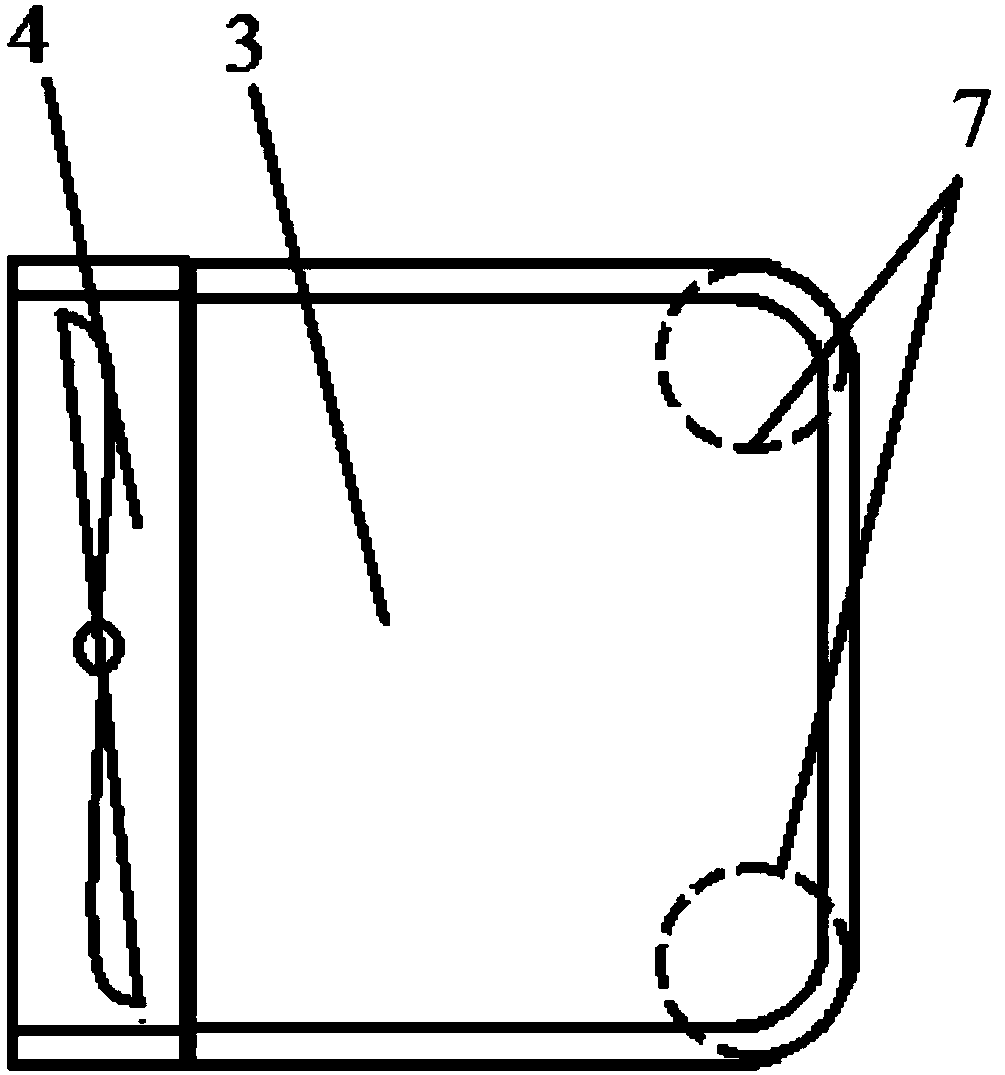

[0029] like image 3 , 4 As shown, the difference between this embodiment and Embodiment 1 lies in the structure of the negative pressure punching conveyor belt 1 and the negative pressure chamber 3 at the discharge end. The discharge end is provided with at least two conveying rollers 7, and the perforated belt 8 of the discharge end is attached to the upper and lower sides of the negative pressure chamber 3 and the side facing the discharge end. Two of the conveying rollers 7 at the discharge end are respectively arranged at the upper and lower ends of the negative pressure chamber 3 facing the discharge end. The side of the negative pressure chamber 3 facing the discharge end is rectangular, and the edge adopts a rounded structure to facilitate the smooth transportation of the tobacco leaves 6. The radius of the rounded corner is equivalent to the radius of the conveying roller 7 set here.

Embodiment 3

[0031] The structure of this embodiment is similar to that of Embodiment 2, the difference is that the side of the negative pressure chamber 3 facing the discharge end is a semicircular arc surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com