Detecting equipment for fan blades of wind turbine

A technology for wind power generators and testing equipment, which is applied in the direction of measuring devices, optical testing of flaws/defects, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves. Efficiency and other issues, to achieve the effect of easy repair, reduce strength, and realize automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

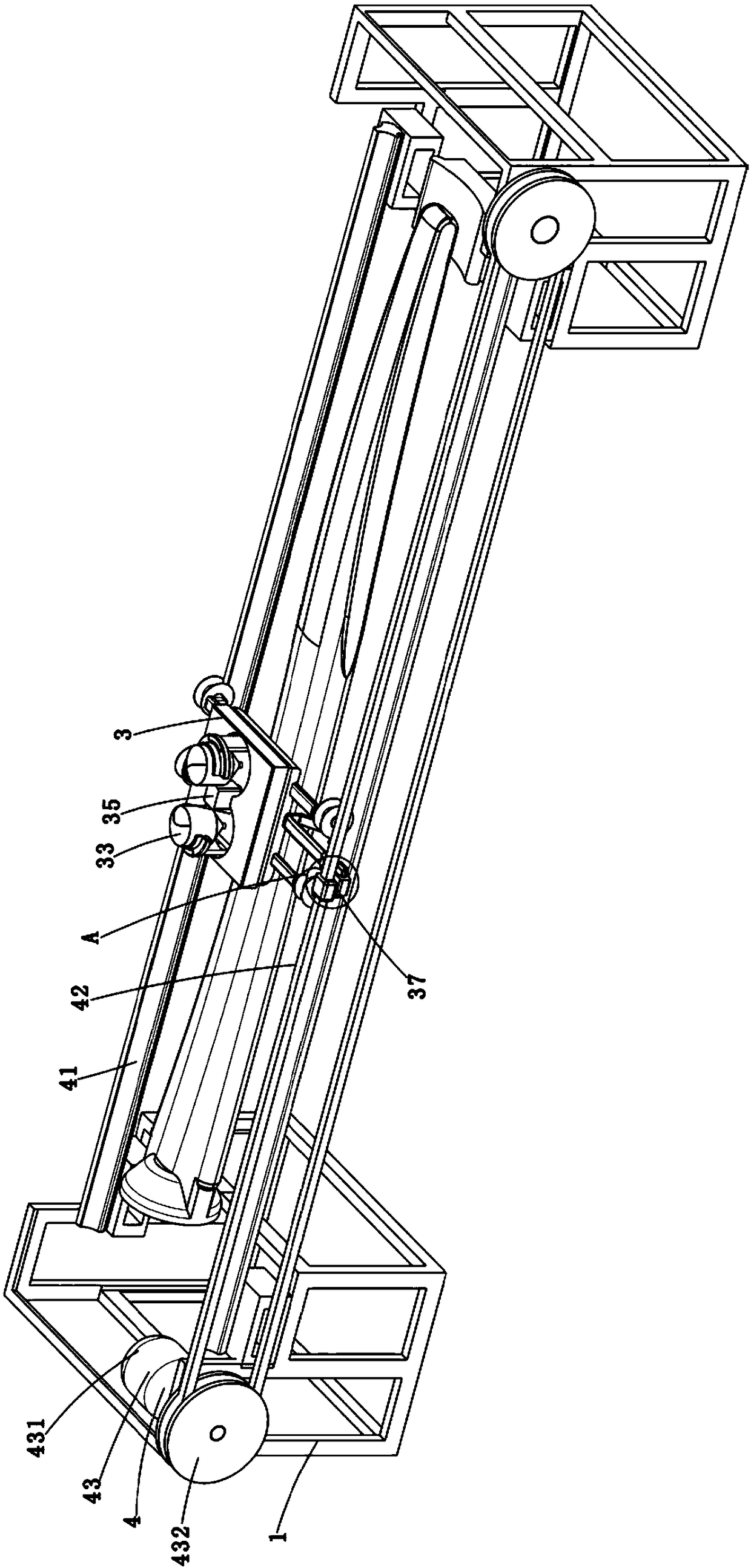

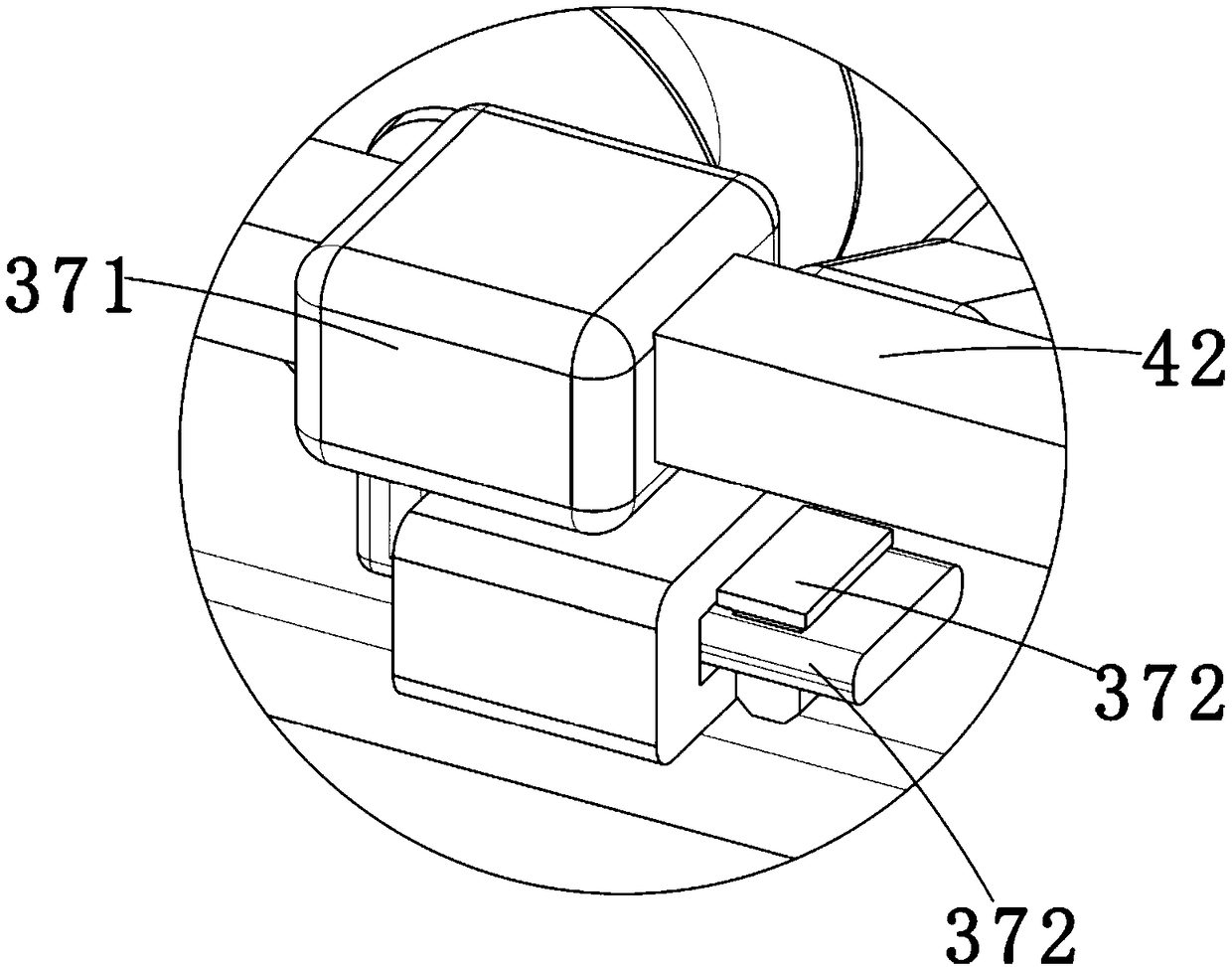

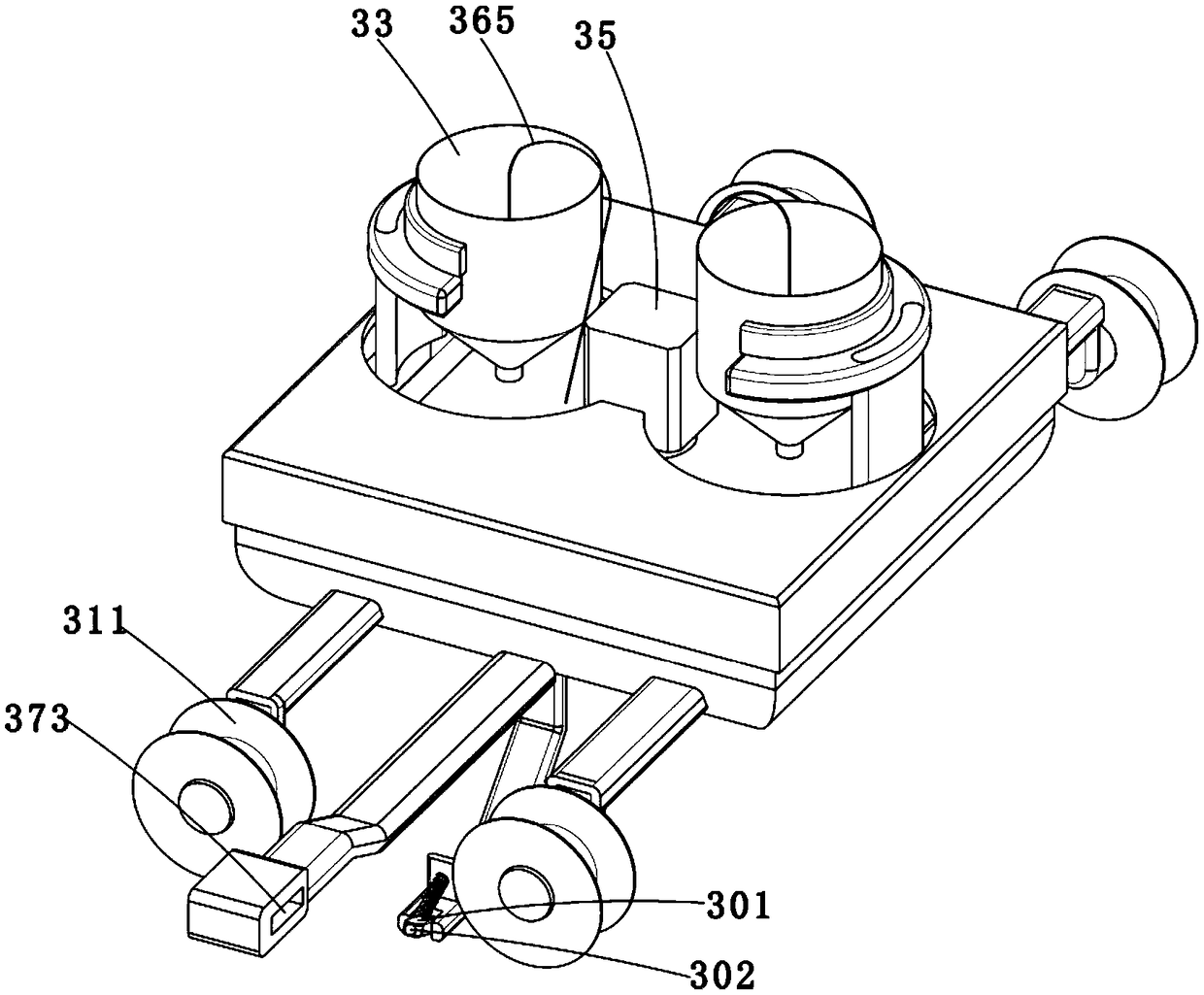

[0039] Such as Figure 1-11 As shown, a detection device for wind turbine blades includes a frame 1, a detection device 2, a marking device 3 and a driving device 4, wherein the frame 1 is a metal frame, and the frame 1 is two , the fan blades are mounted on two racks 1; the detection device 2 can scan and image the surface of the fan blades, and then transmit the collected images to the computer in real time through radio technology, and manually Cracks and damages on the fan blades are directly judged in front of the computer. The detection device 2 includes a plurality of cameras 21 and a lower road plate 22. It is a prior art, so it will not be described in detail here; When the device 2 finds damage and cracks, draw two marking lines on the surface of the fan blade, and the damage and cracks are between the two marking lines; the driving device 4 can be used to pull the marking device 3 to move forward and backward, and The driving device 4 supplies power to the detectio...

Embodiment 2

[0048] Such as Figure 12-14 As shown, this implementation discloses a pull-off device 5 for moving the marking device away from the driving device, and the pull-off device 5 is arranged on the frame 1; specifically: the pull-off device 5 includes a mechanical claw part 51, a lifting part 52 and a rotating part 53. The mechanical claw part 51 includes an n-shaped mechanical arm 511, a grasping part 512 and an anti-off part 513. The mechanical arm 511 is a metal arm. The gripper 512 is connected to one end of the mechanical arm 511 by screws, the gripper 512 is a metal frame with four n-shaped mechanical claws 516, and each mechanical claw 516 can be set on the frame body On the four legs of 31, there is a pin hole on the mechanical claw 512, and the anti-off piece 513 passes through the pin hole. Specifically, the anti-off piece 513 is a T-shaped metal strip. The end of the anti-off piece 513 has a pin hole, and a T-shaped metal pin can be inserted on the end of the anti-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com