Method and system for COB optical module automatic coupling dispensing curing

An automatic coupling and curing method technology, which is applied to the coupling of optical waveguides, pretreatment of the surface, and devices for coating liquid on the surface, etc., can solve the problems of increasing the work intensity of operators and reducing the efficiency of chip dispensing and curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A COB optical module automatic coupling dispensing curing method, it comprises the steps:

[0044] Step 1. Obtain the coupling requirements between the chip 9 and the lens when dispensing;

[0045] Step 2, determining the clamping mode of the first clamping mechanism 2 for the chip 9;

[0046] Step 3, determining the clamping mode and feeding route of the second clamping mechanism 3 for the lens;

[0047] Step 4. Determine the dispensing route and dispensing method of the dispensing mechanism 4 according to the positional relationship between the chip 9 and the lens and dispensing requirements;

[0048] Step 5. Determine the heating time, heating temperature and heating method of the heating mechanism 5 according to the positional relationship between the chip 9 and the lens and according to the curing requirements;

[0049] Step 6, converting the above requirements into preset parameters and performing presets in the adjustment control mechanism;

[0050] Step 7: St...

Embodiment 2

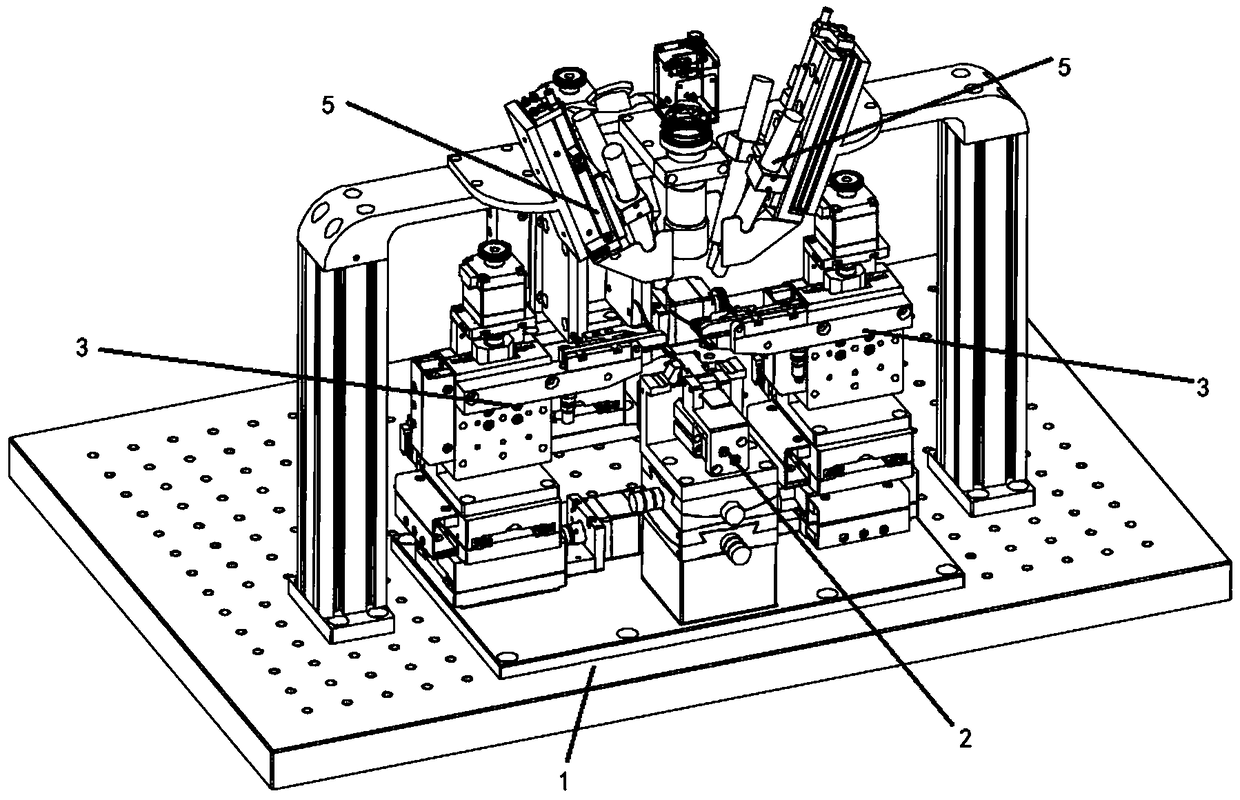

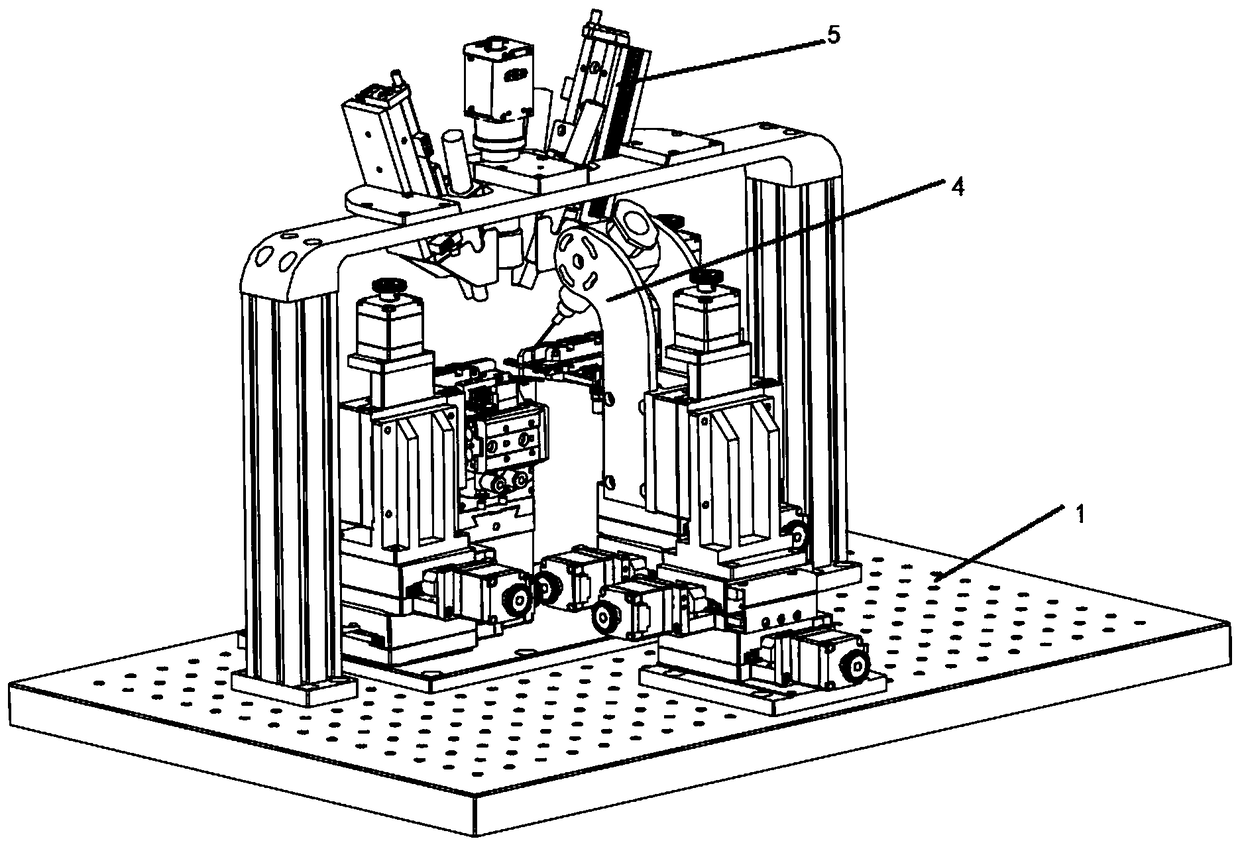

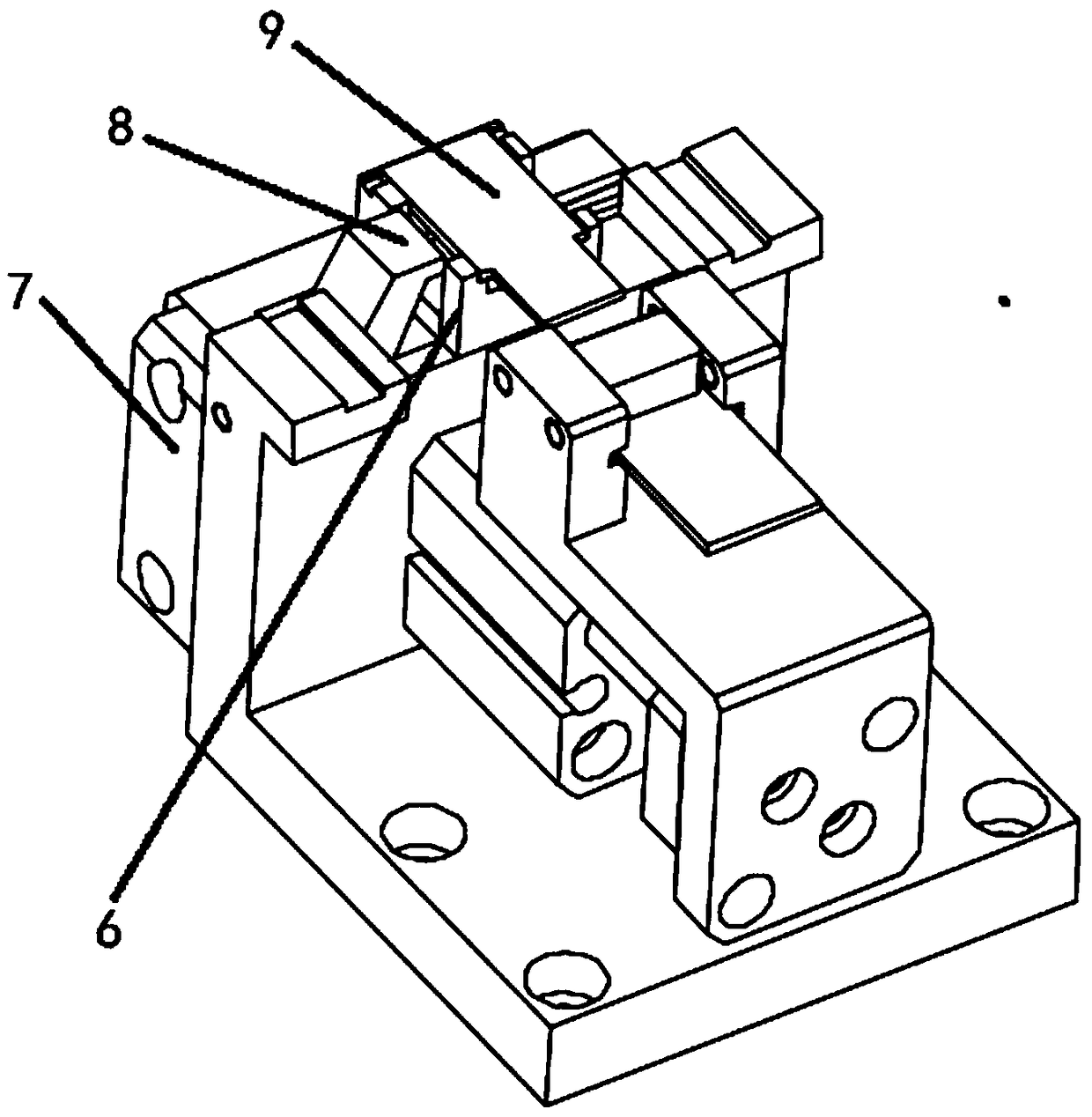

[0062] Such as figure 1 and 2 As shown, on the basis of Embodiment 1, this embodiment further provides a COB optical module automatic coupling dispensing and curing system, which includes a support base 1, at least one first clamping mechanism 2, and at least one second clamping mechanism 3. Dispensing mechanism 4, heating mechanism 5, and adjustment control mechanism; the first clamping mechanism 2 includes a preliminary positioning structure 6 and a locking structure 7, and the second clamping mechanism 3 includes a clamping structure and a feeding structure, The adjustment control mechanism adjusts and controls the first clamping mechanism 2, the second clamping mechanism 3, the glue dispensing mechanism 4 and the heating mechanism 5 according to preset parameters; wherein, the preliminary positioning After the chip 9 is initially positioned by the structure 6, the adjustment control mechanism instructs the locking structure 7 to lock the chip 9; the clamping structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com