A matter-element model evaluation method of reinforcement corrosion in reinforced concrete based on ideal point method

A technology for corrosion of reinforced concrete and steel bars, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc. It can solve the problem of not having a perfect evaluation method, and achieve the effect of reducing human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

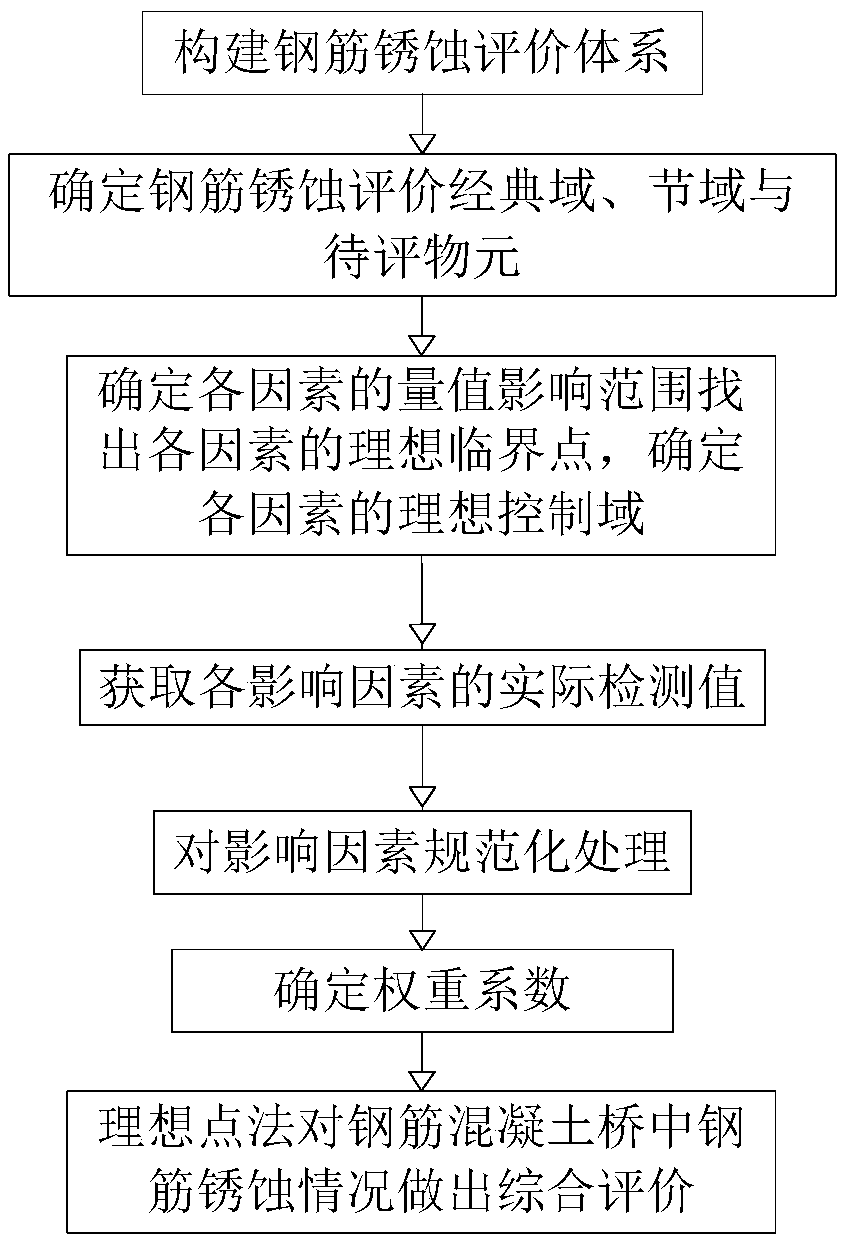

Method used

Image

Examples

Embodiment

[0083] First, build a steel corrosion evaluation system to determine the factors affecting steel corrosion in reinforced concrete and the range of influence of each factor to provide data support for subsequent analysis. According to relevant materials and similar engineering documents, the standard data of various parameters of reinforced concrete beams in this section are shown in Table 4.

[0084] The actual project inspection data is shown in Table 4:

[0085] Table 4 Project actual testing data

[0086]

[0087] According to the standard value, the weight coefficients of different influencing factors are determined by the multiple influencing factors in the evaluation unit as shown in Table 5:

[0088] Table 5 Weights of factors affecting steel corrosion in reinforced concrete

[0089]

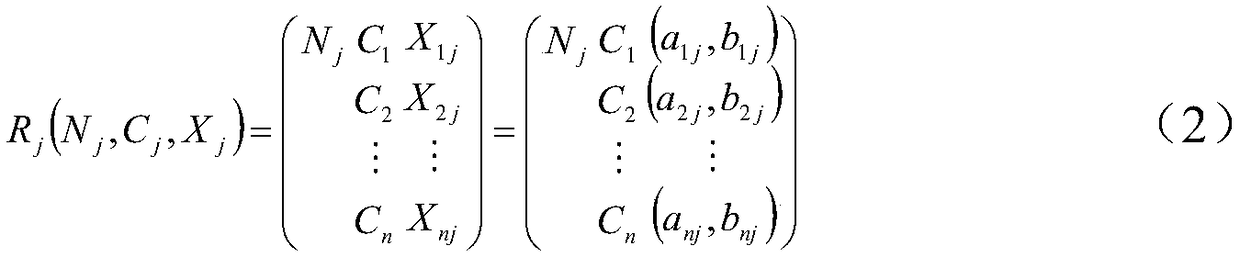

[0090] Perform data standardization processing on the standard values of influencing factors to obtain a relative rank matrix

[0091]

[0092] According to the ideal point method, the actual de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com