Automatic detection method of track turnout notch

An automatic detection and rail technology, which is used in railway vehicle shape measuring instruments, railway car body parts, railway auxiliary equipment, etc., can solve the problems of inability to eliminate interference lines, inability to detect the status of rail forks in real time, and lack of image texture detection, etc. Achieve intuitiveness and accuracy, and avoid the effect of on-site opening inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

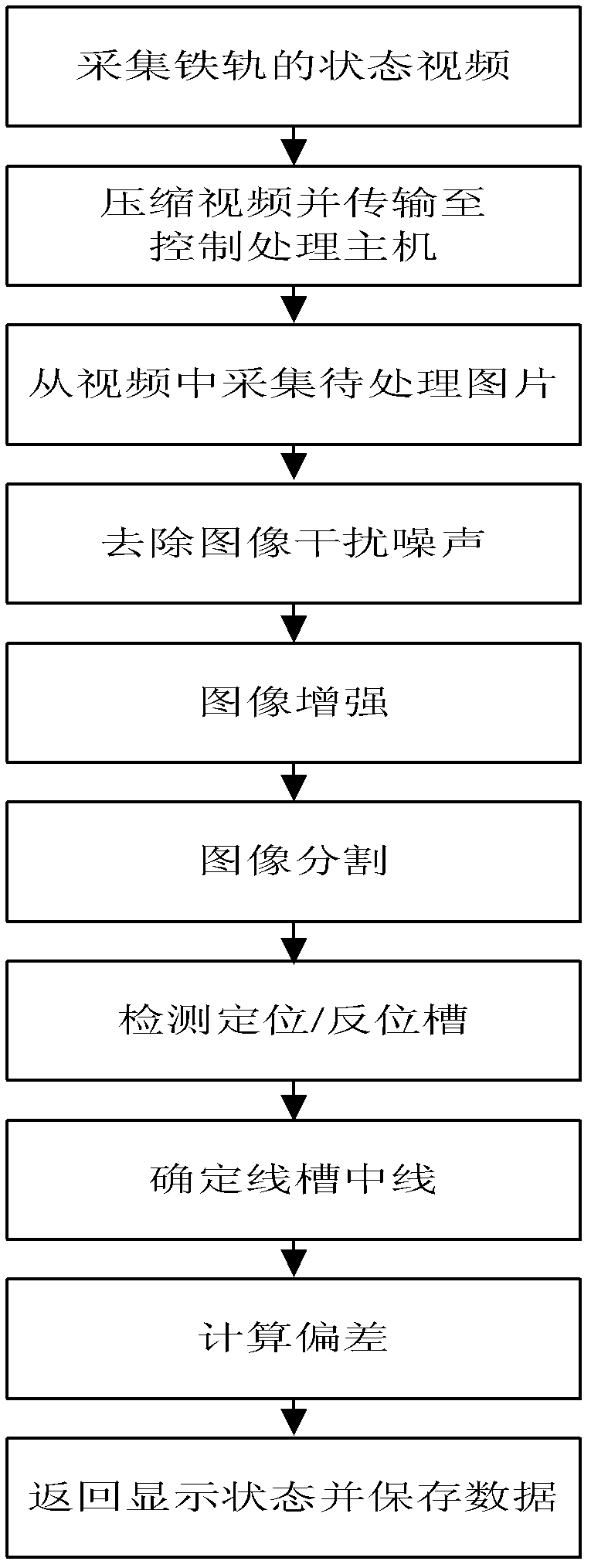

[0056] The first step is to collect the status video image of the railway track

[0057] A CCD camera with a resolution of 800*600 is used to collect video images of the status of the rails. The camera has a frame rate of 30 frames per second and uses LED supplementary light. The number of acquisitions is 8 times per day, and the length of each acquisition video image is 8 minutes;

[0058] The second step is the processing of the state video images of the collected railroad tracks

[0059] 2.1 Preparation before processing

[0060] Compress and transmit the state video image of the rail track collected in the first step to the control processing host, and calculate the conversion rate at the current computer resolution, that is, convert the pixel unit used by the computer to calculate or analyze the image into the international unit mm / per pixel, The conversion rate is 0.0776mm / pixel;

[0061] 2.2 Processing of early video images

[0062] 2.2.1 Open the video and capture t...

Embodiment 2

[0088] The first step is to collect the status video image of the railway track

[0089] A CCD camera with a resolution of 1024*768 is used to collect video images of the status of the rails. The camera has a frame rate of 35 frames per second, and uses LED supplementary light. The number of acquisitions is 10 times / day, and the length of each acquisition video image is 10 minutes;

[0090] The second step is the processing of the state video images of the collected railroad tracks

[0091] 2.1 Preparation before processing

[0092] Compress and transmit the state video image of the rail track collected in the first step to the control processing host, and calculate the conversion rate at the current computer resolution, that is, convert the pixel unit used by the computer to calculate or analyze the image into the international unit mm / per pixel, The conversion rate is 0.0776mm / pixel;

[0093] 2.2 Processing of early video images

[0094] 2.2.1 Open the video, capture the ...

Embodiment 3

[0120] The first step is to collect the status video image of the railway track

[0121] A 1440*900 resolution CCD camera is used to collect rail status video images. The camera has 40 frames per second and LED supplementary light. The number of collections is 12 times / day, and the length of each video image collection is 8 minutes;

[0122] The second step is the processing of the state video images of the collected railroad tracks

[0123] 2.1 Preparation before processing

[0124] Compress and transmit the state video image of the rail track collected in the first step to the control processing host, and calculate the conversion rate at the current computer resolution, that is, convert the pixel unit used by the computer to calculate or analyze the image into the international unit mm / per pixel, The conversion rate is 0.0776mm / pixel;

[0125] 2.2 Processing of early video images

[0126] 2.2.1 Turn on the video and capture the last frame image of the state video image co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com