Multi-point pushing cumulative-gliding construction method for steel roof truss

A technology of cumulative slippage and construction method, applied in the direction of roof, building components, hydraulic program control, etc., can solve the problem of not being at the same level, etc., to reduce the deflection, ensure the total construction period, and prevent the rails from moving together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

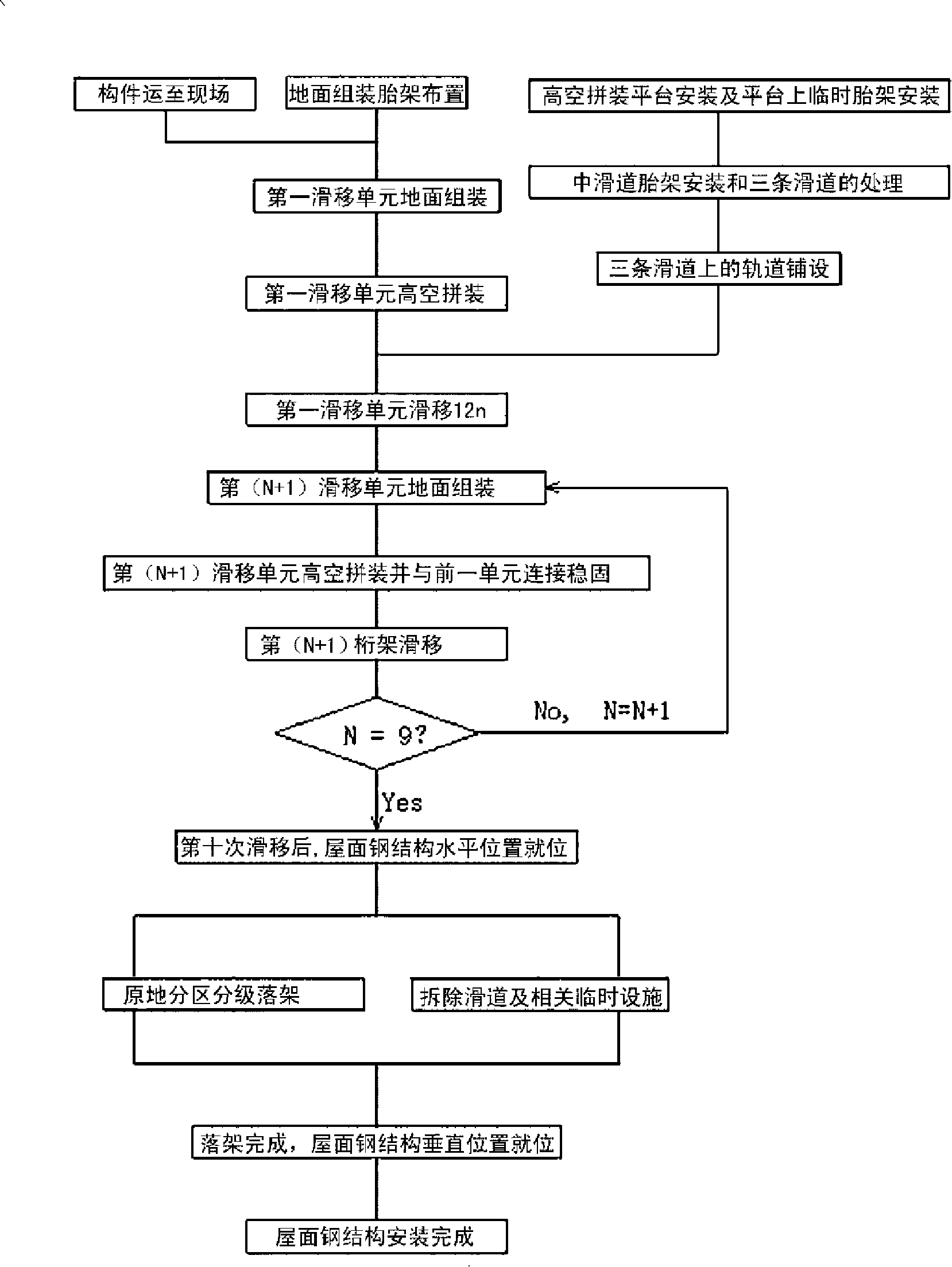

[0072] Examples see Picture 1-1 3, this steel roof truss multi-point push cumulative slip construction method:

[0073] First set up a sliding support system with three slideways and six slideways. One end of the main structure is used as the starting position of the sliding. The main structure is a concrete structure or a steel structure. A high-altitude assembly platform 10 is installed at the starting position of the sliding. The assembly platform provides a support system and a working platform for the high-altitude assembly of the truss.

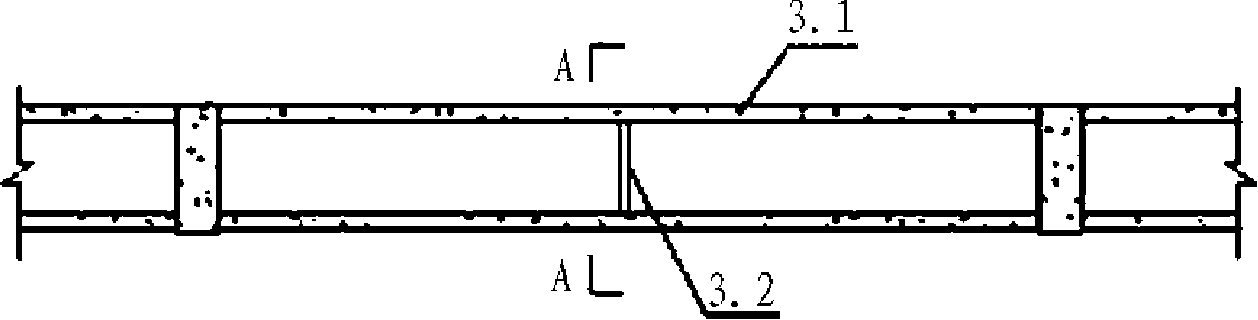

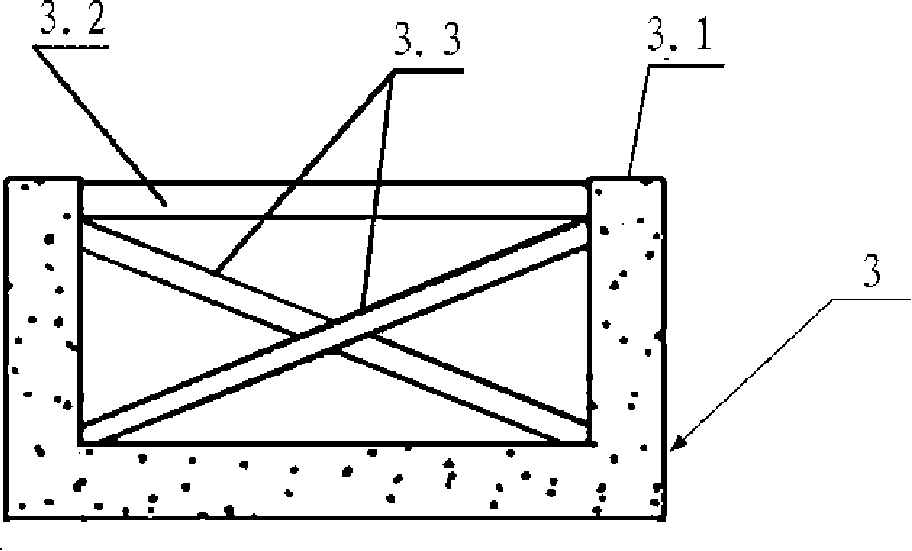

[0074] see figure 2 , 3 Concrete channel beams 3 are respectively erected on the structural columns 2 on the left and right sides of the main structure, side slide rails 1 are laid on the two limb walls of each concrete channel beam, and the connection level between the two limb walls 3.1 of the concrete channel beam Support bar 3.2, cross support bar 3.3. Set up a row of middle slideways temporarily supporting the tire frame 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com