Multi-objective optimization-based design method for converter for electric automobile

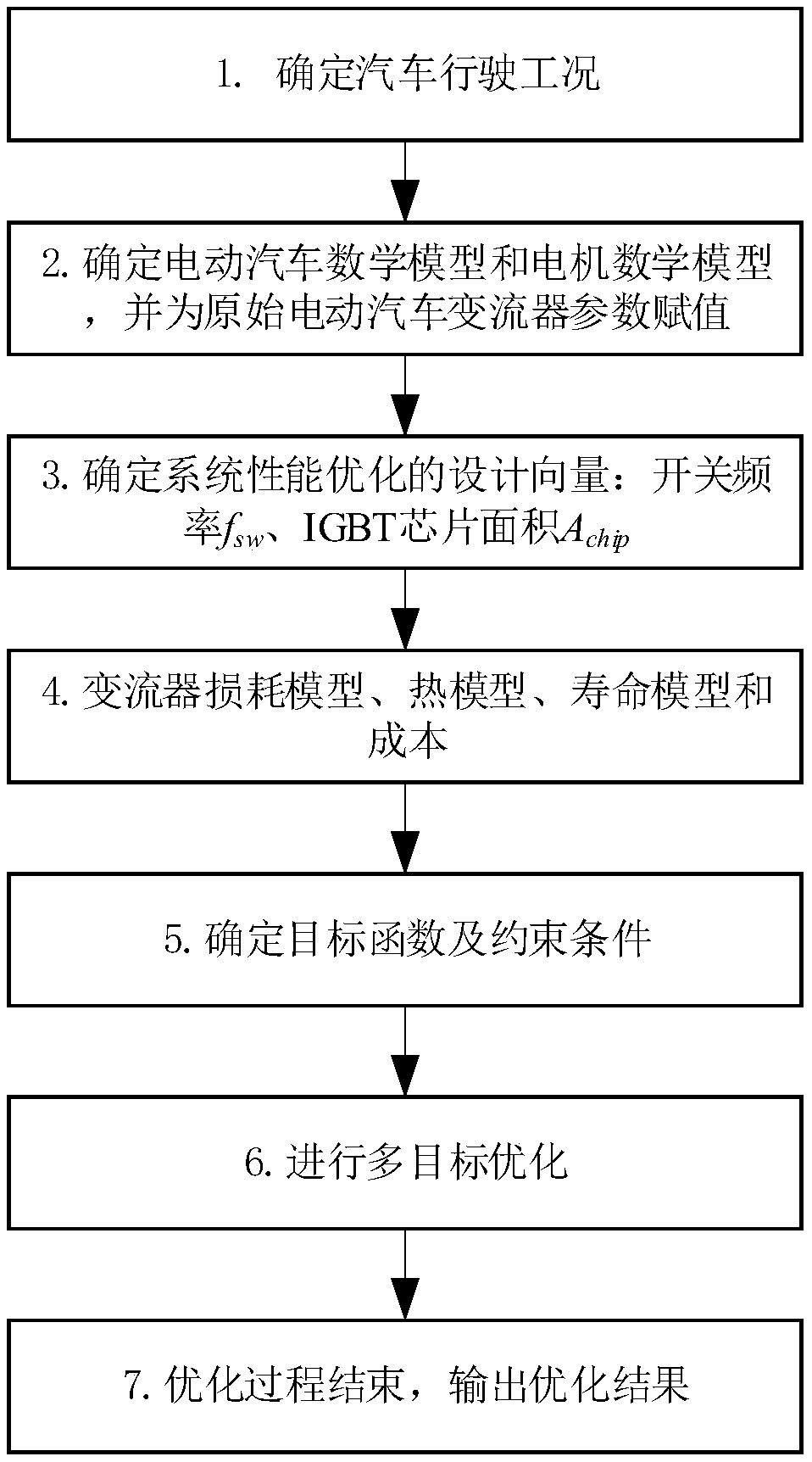

A multi-objective optimization and electric vehicle technology, applied in the design field of electric vehicle converters, can solve problems such as insufficient performance indicators, less reliability involved, no attention to electric vehicle converters, etc., to improve product competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

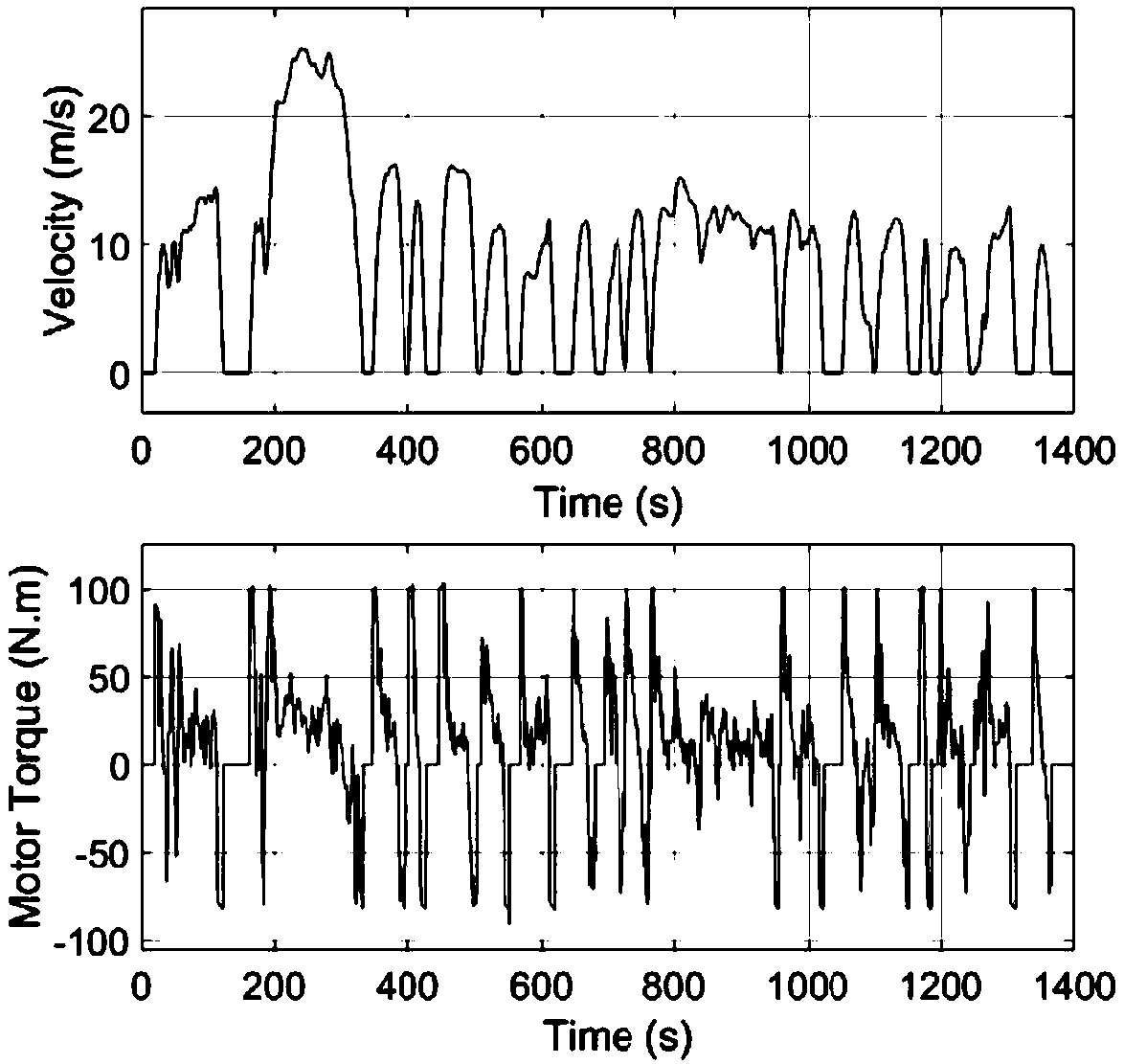

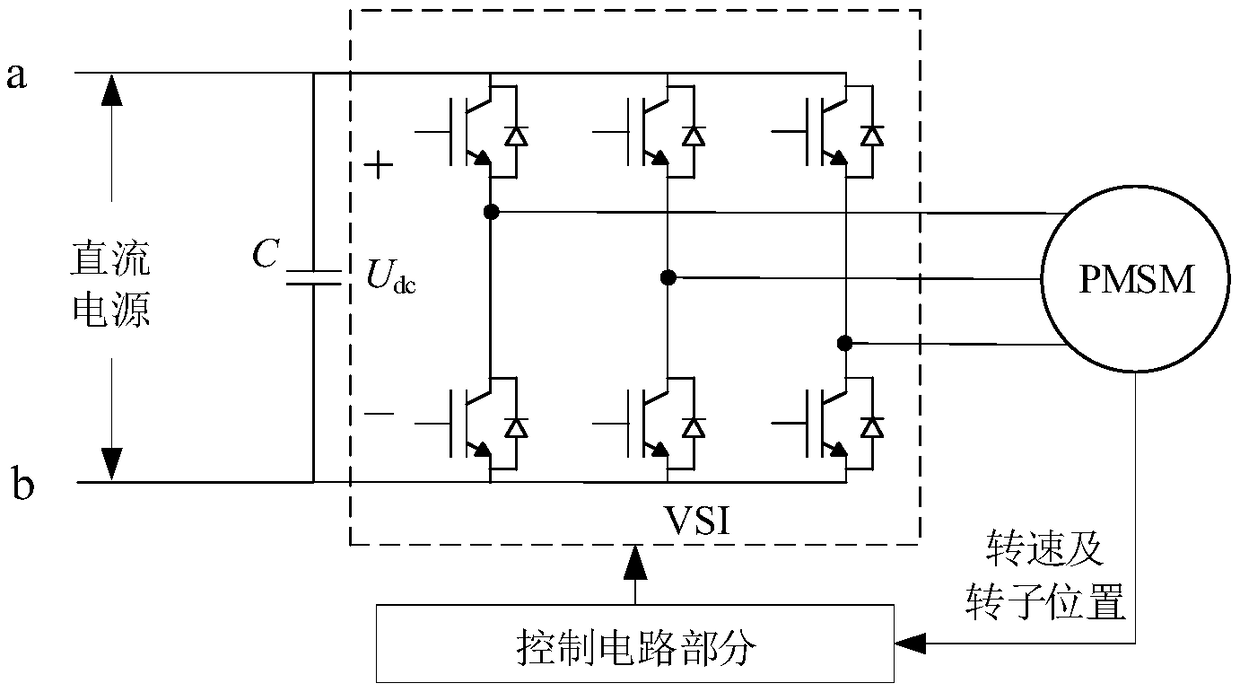

[0106] Taking an electric vehicle as an example, the original parameters of the electric vehicle and motor in step 2 are shown in Table 1 and Table 2. The test conditions of the electric vehicle are the standard (UDDS) cycle conditions. Substitute the original parameters of the electric vehicle and motor into the loss model and thermal model of the converter, and select a set of design variables (f sw , A chip ) = (10kHz, 70mm 2 ), according to step 1 to step 4, the junction temperature variation curve of the IGBT chip can be obtained, such as Figure 5 shown; from Figure 5 It can be seen that in the acceleration phase of the car, the IGBT junction temperature rises sharply, and in the deceleration phase, the junction temperature drops rapidly, while the junction temperature fluctuates slowly in the constant speed phase. Figure 6is the relationship between the specific energy consumption ε, the first fault mileage γ and the specific cost σ of the electric vehicle converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com