Integrated equipment and method capable of completing 3D wig preparation

A wig and 3D technology, applied in the field of fully formed 3D elastic bionic hair products, can solve the problems of many production processes, low production efficiency, and easy occurrence of defective products, and achieve the effect of good wearability, excellent elasticity and beautiful hairstyle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

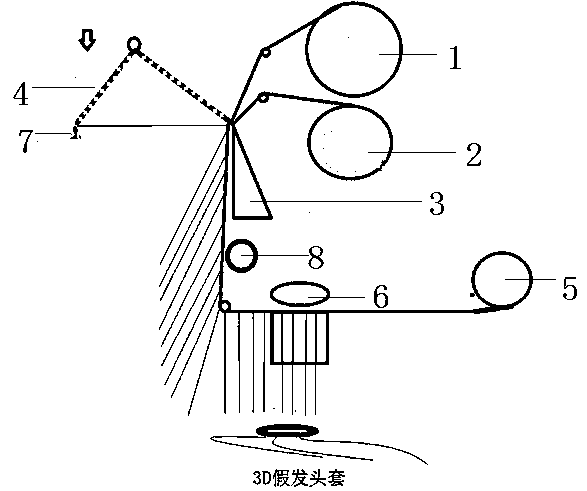

[0020] The integrated equipment capable of completing the preparation of 3D wigs in this embodiment consists of a wig head 1, a base cloth head 2, a jacquard warp knitting machine 3, a wig swing arm 4, a 3D film punching machine 6, scrap reels 5, and hooks 7 and a cutting device. According to the design of women's short hair with a length of 35 cm, the swing arm of the wig is adjusted to a swing range of 30 cm according to the length of the hair. Synchronously, the wig silk pan head outputs the wig silk to participate in weaving. Synchronous base fabric and thermal fuse pan head output meet the warp knitting machine knitting, wig, base fabric and thermal fuse common needle position knitting at the design position. Among them, the length of the hair is fixed by the hook, and the position of the hook cooperates with the hair supply of the hair pan to complete the positioning of the length of the hair. The laser slitting of the 3D film punching machine cuts the hair at the desig...

Embodiment 2

[0022] The integrated equipment capable of completing the preparation of 3D wigs in this embodiment consists of a wig head, a base cloth head, a jacquard warp knitting machine, a wig swing arm, a 3D punching machine for shaping, scrap reels, a wig swing arm, hooks and points. cutting device. According to the design of men's short hair with a length of 5 cm, the swing arm of the wig is adjusted to swing 5 cm according to the length of the hair. Synchronously, the wig silk pan head outputs the wig silk to participate in weaving. Synchronous base fabric and thermal fuse pan head output meet the warp knitting machine knitting, wig, base fabric and thermal fuse common needle position knitting at the design position. Among them, the length of the hair is fixed by the hook, and the position of the hook cooperates with the hair supply of the hair pan to complete the positioning of the length of the hair. The laser slitting of the 3D film punching machine cuts the hair at the design p...

Embodiment 3

[0024] The integrated equipment capable of completing the preparation of 3D wigs in this embodiment consists of a wig head, a base cloth head, a jacquard warp knitting machine, a wig swing arm, a 3D punching machine for shaping, scrap reels, a wig swing arm, hooks and points. cutting device. According to the 15cm long fake beard design, the wig swing arm adjusts the swing range of 15cm according to the length of the fake beard, synchronously, the wig silk pan head outputs the wig silk to participate in weaving. Synchronous base fabric and thermal fuse pan head output meet the warp knitting machine knitting, wig, base fabric and thermal fuse common needle position knitting at the design position. Among them, the length of the hair is fixed by the hook, and the position of the hook cooperates with the hair supply of the hair pan to complete the positioning of the length of the hair. The laser slitting of the 3D film punching machine cuts the hair at the design position to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com