Volumetric flask fixture

A technology of fixing devices and volumetric flasks, which is applied in the field of chemical experiment instruments, can solve problems such as unsmooth experiments, dumping and shaking, floating on water, etc., and achieve the effect of ensuring the effect of ultrasonic cleaning and smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

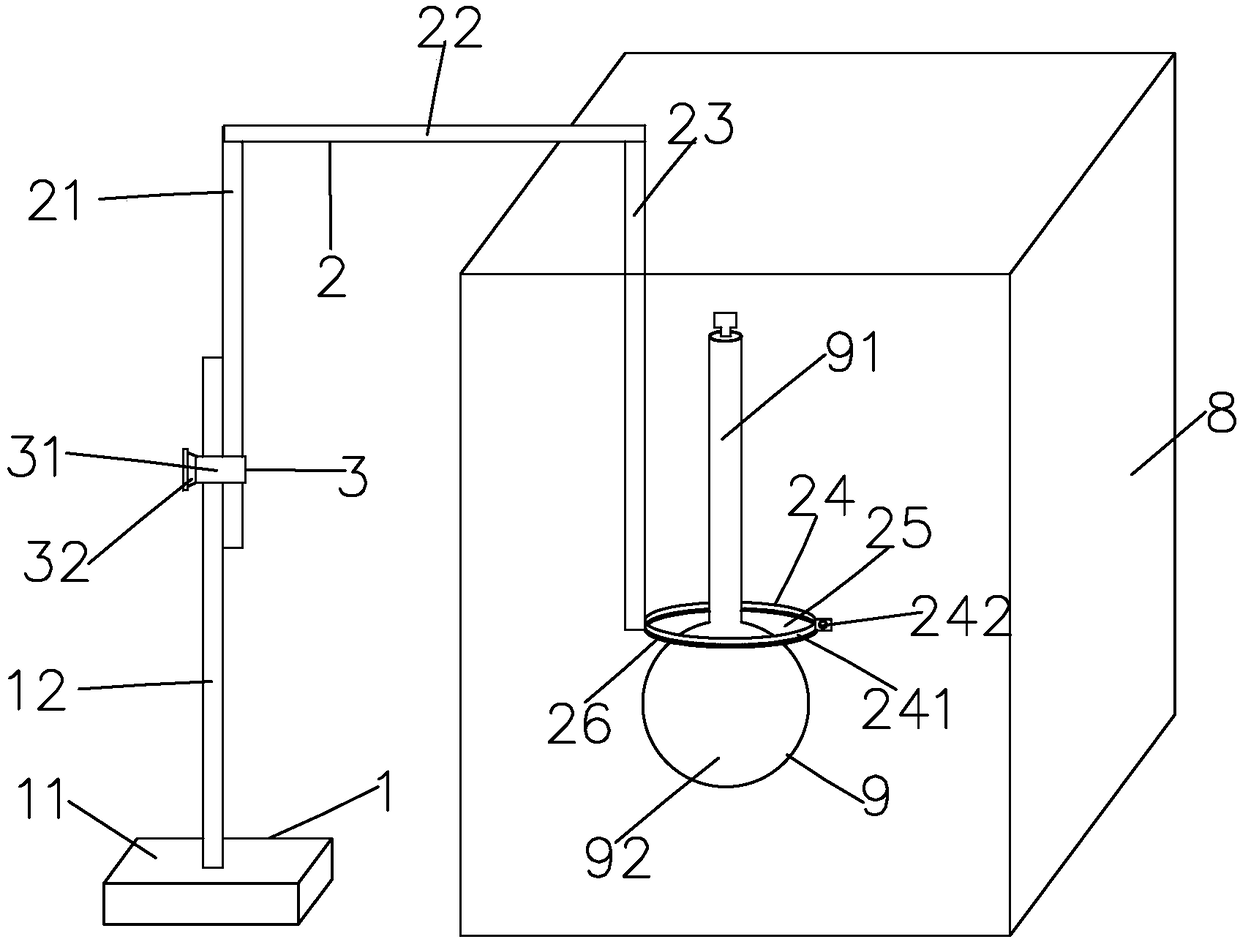

[0029] see figure 1 , the present invention provides a volumetric flask fixing device for fixing a volumetric flask 9 in a liquid, comprising a main body seat 1 and an anti-floating bracket 2 installed on the main body seat 1 .

[0030] Specifically, the main body seat 1 includes a base 11 and a connecting rod 12 vertically fixed on the base 11 .

[0031] Specifically, the anti-floating bracket 2 includes a first upright bar 21 vertically connected to the connecting rod 12, a horizontally arranged cross bar 22 connected at one end to the upper end of the first upright bar 21, an upper end connected to the cross bar 22, the second vertical rod 23 connected to the other end and the anti-floating member 24 arranged at the lower end of the second verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com