Method and system for controlling corner deformation of laser welding T-joint

A laser welding and deformation control technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high cost of tooling, angular deformation of T-joints, complicated process, etc., and achieve the effect of reducing welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

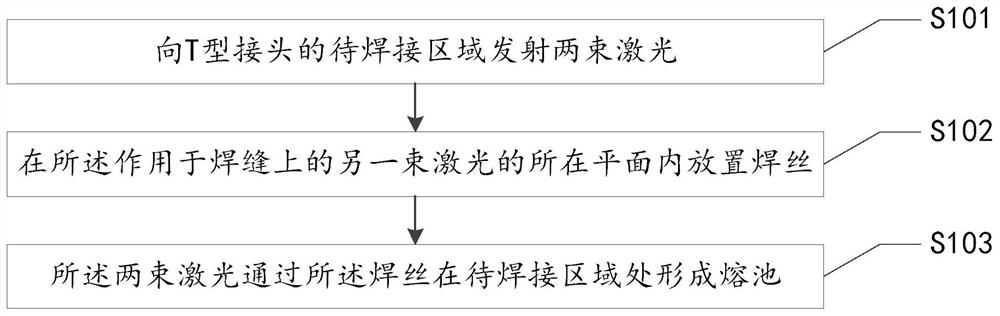

[0033] Such as figure 1 As shown, this embodiment proposes a method for controlling the angular deformation of a laser welded T-joint, the method comprising:

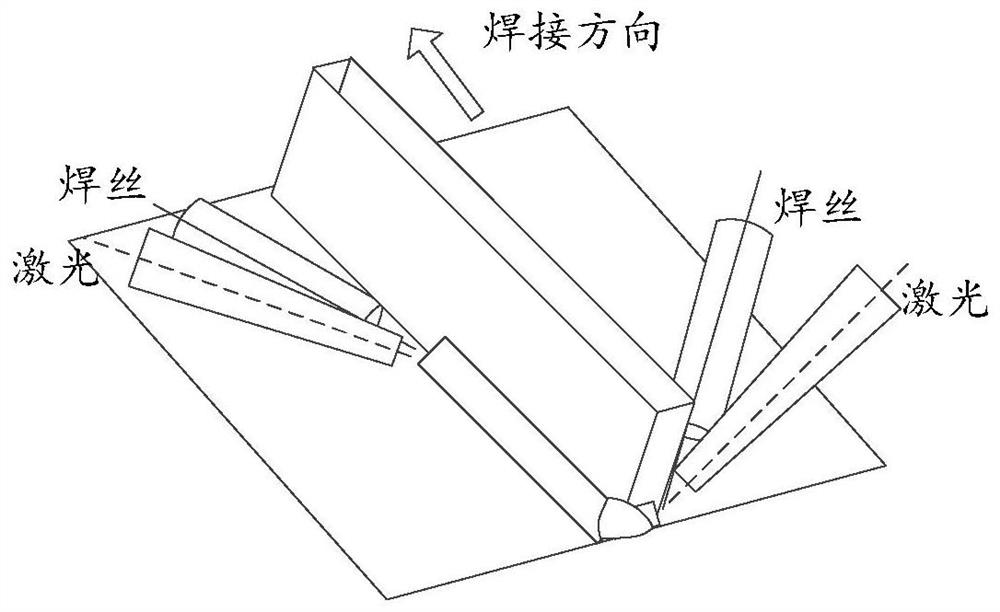

[0034] S101. Emit two laser beams to the area to be welded of the T-shaped joint, the two laser beams are located on the same side of the T-shaped joint; wherein, one of the two laser beams acts on the tendons of the T-shaped joint On the strip, another beam of laser acts on the weld between the rib and the bottom plate of the T-joint;

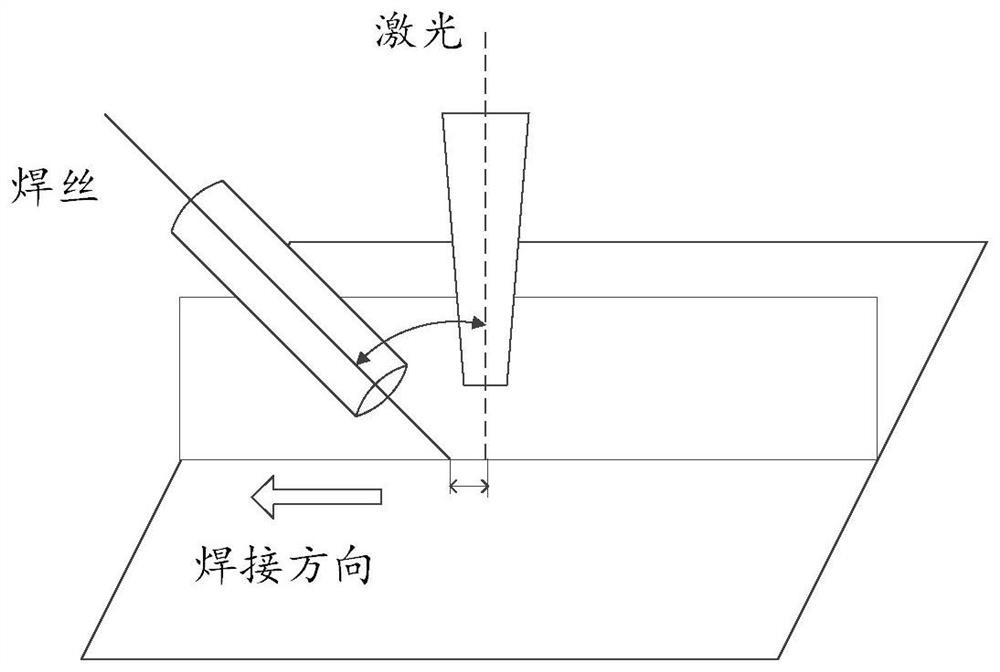

[0035] S102. Place the welding wire in the plane where the other laser beam acting on the weld seam is located;

[0036] S103. The two laser beams pass through the welding wire to form a molten pool at the area to be welded.

[0037] Specifically, in this embodiment, a high-power Nd.YAG or fiber laser is firstly used as a laser emission source, and the laser light emitted by the laser is split to generate two laser beams through a dual-beam spot welding joint with a splitting function...

Embodiment 2

[0041] Such as Figure 9 As shown, this embodiment proposes a laser welding T-joint angular deformation control system, the system includes a laser and a welding head;

[0042] The laser is used to generate laser light and send the laser light to the welding head;

[0043] The welding head is used to split the laser light sent by the laser into two laser beams, and emit the two laser beams to the area to be welded of the T-shaped joint, so that the two laser beams pass through the welding wire in the area to be welded A molten pool is formed.

[0044]Specifically, in this embodiment, a high-power Nd.YAG or fiber laser is firstly used as a laser emission source, and the laser light emitted by the laser is split to generate two laser beams through a dual-beam spot welding joint with a splitting function. There are two laser beams on both sides of the T-joint rib, which can be welded simultaneously or sequentially. The two laser beams act on the area to be welded respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com