Production method of threaded pipe pile with adjustable diameter and wall thickness

A production method and technology for threaded pipes, which are applied in sheet pile walls, construction, infrastructure engineering, etc., can solve the problems that large-diameter pipe piles cannot be changed in thickness and diameter, and achieve the effects of high production efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

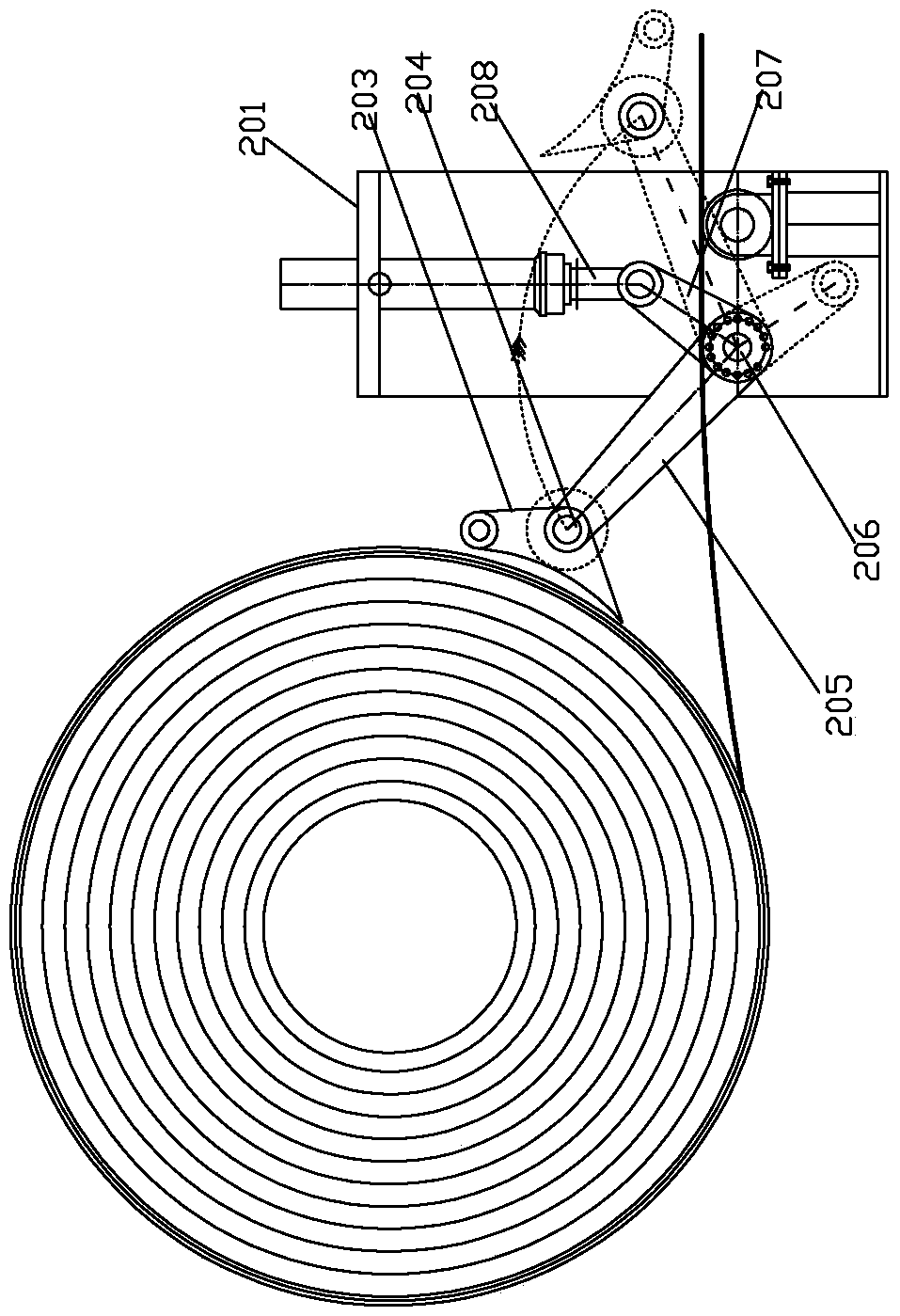

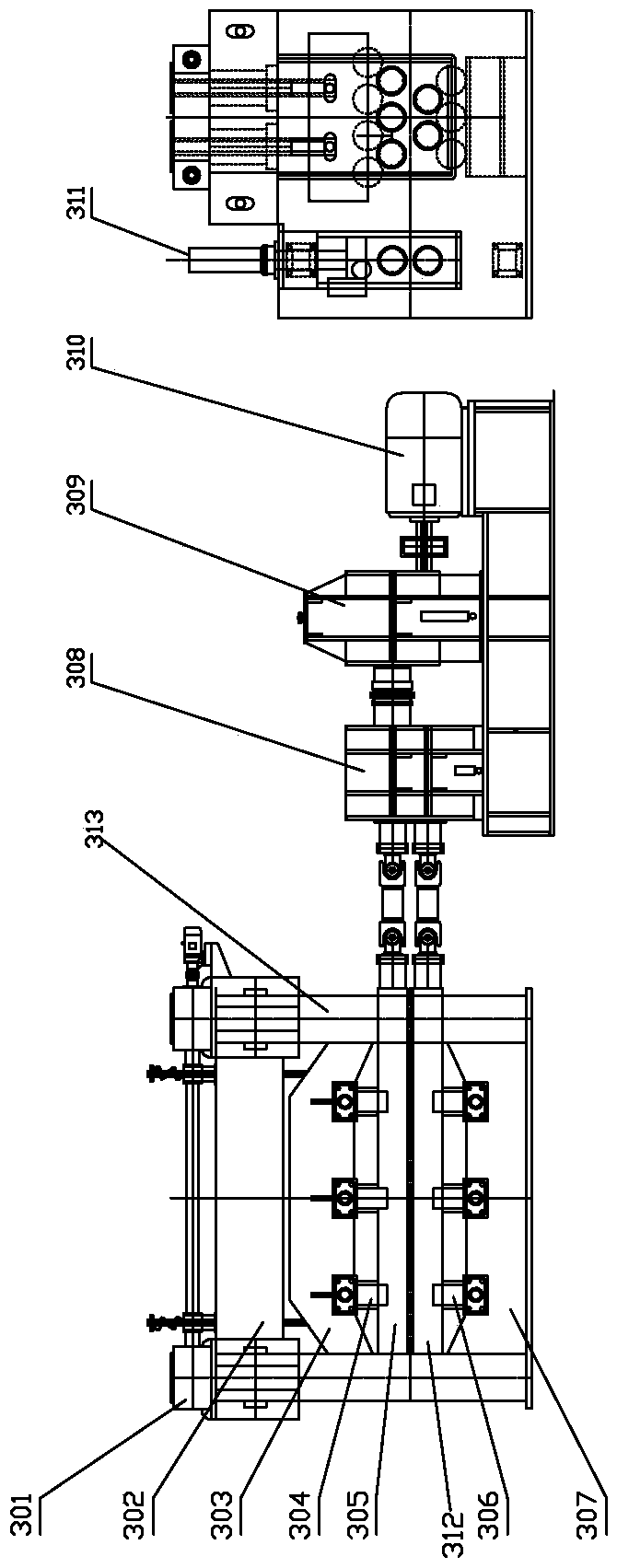

[0037] Such as Figure 1-7 shown.

[0038] A method for producing threaded pipe piles with adjustable diameter and wall thickness, comprising the following steps:

[0039] First, calculate the corresponding weight steel strip coil according to the length of pipe piles with different thicknesses;

[0040] Secondly, the steel strip coil of the first thickness is placed on the feeder and uncoiled;

[0041] Thirdly, send the uncoiled steel strip to the pinch leveler for traction, and at the same time make the original coiled steel strip into a flat belt;

[0042] Fourth, send the leveled steel strip into the edge milling machine for edge milling, so that both sides of the steel strip form grooves that are conducive to welding and forming;

[0043] Fifth, use electric vertical rollers to guide and straighten, so that the strip steel moves forward in a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com