Thread tubular pile production line with adjustable diameter and wall thickness

A threaded pipe and production line technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem that large-diameter pipe piles cannot achieve variable thickness and diameter, and achieve high production efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] Such as Figure 1-8 shown.

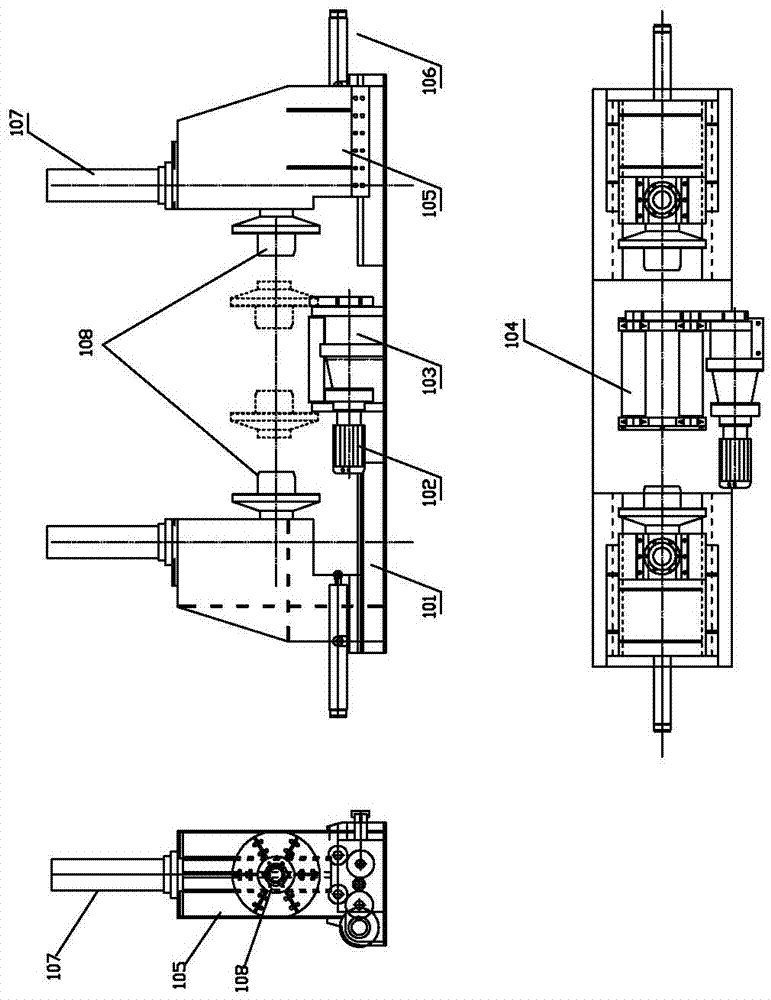

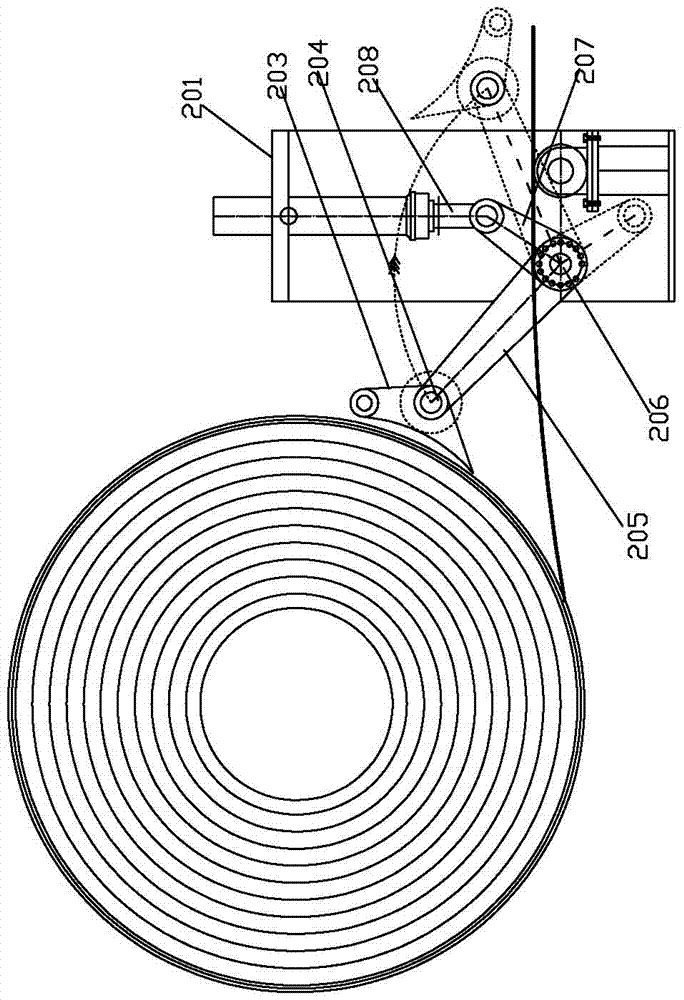

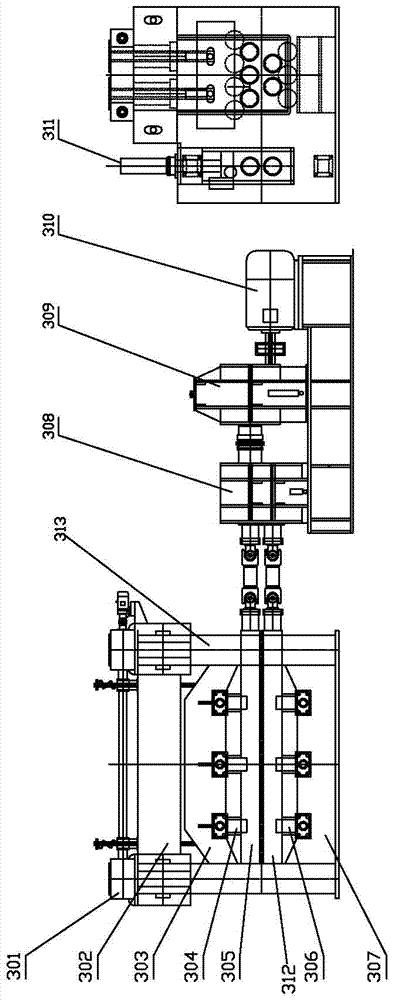

[0030] A threaded pipe pile production line with adjustable diameter and wall thickness, which is mainly composed of a feeder 1, an uncoiler 2, a pinch leveler 3, an edge milling machine 4, a pre-bending platen device 5 and a forming machine 6, such as figure 1 As shown, the steel strip roll enters the feeder 1, is uncoiled by the uncoiler 2, and then sent to the pinch leveler 3 for forward delivery and correction, so that the steel strip in the original curled state becomes a flat plate, and then enters the edge milling machine 4. Mill the two sides into beveled edges to facilitate the welding process of the final forming. The steel strip after milling enters the pre-bending pressing plate device 5 to perform upward pre-bending on both sides and enters the forming machine 6 under the action of the pressing plate Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com