Welding method for side frame of five-axle bogie welding frame for bridge erecting machine

A welding method and bridge erecting machine technology, applied in welding equipment, manufacturing tools, transportation and packaging, etc., can solve problems such as no way to guarantee quality, complicated welding process, low precision, etc., so as to avoid excessive deformation of side frames, Ensure weld penetration and reduce rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

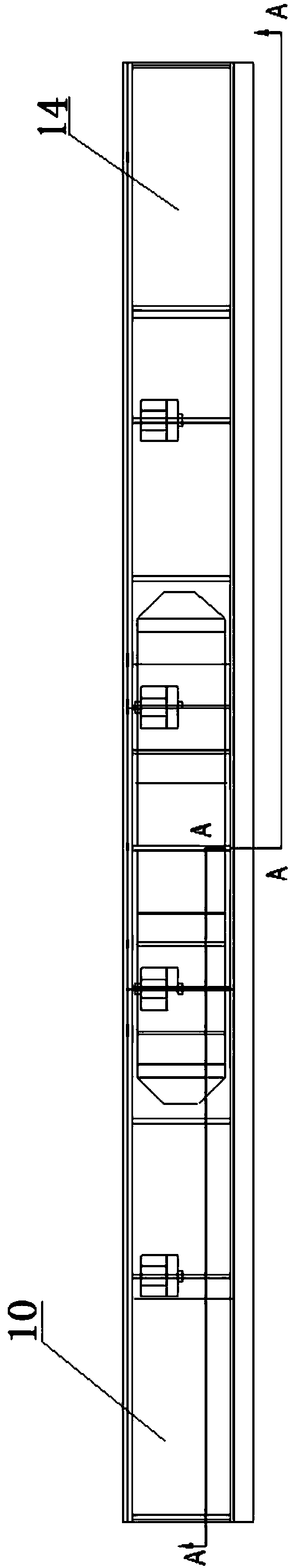

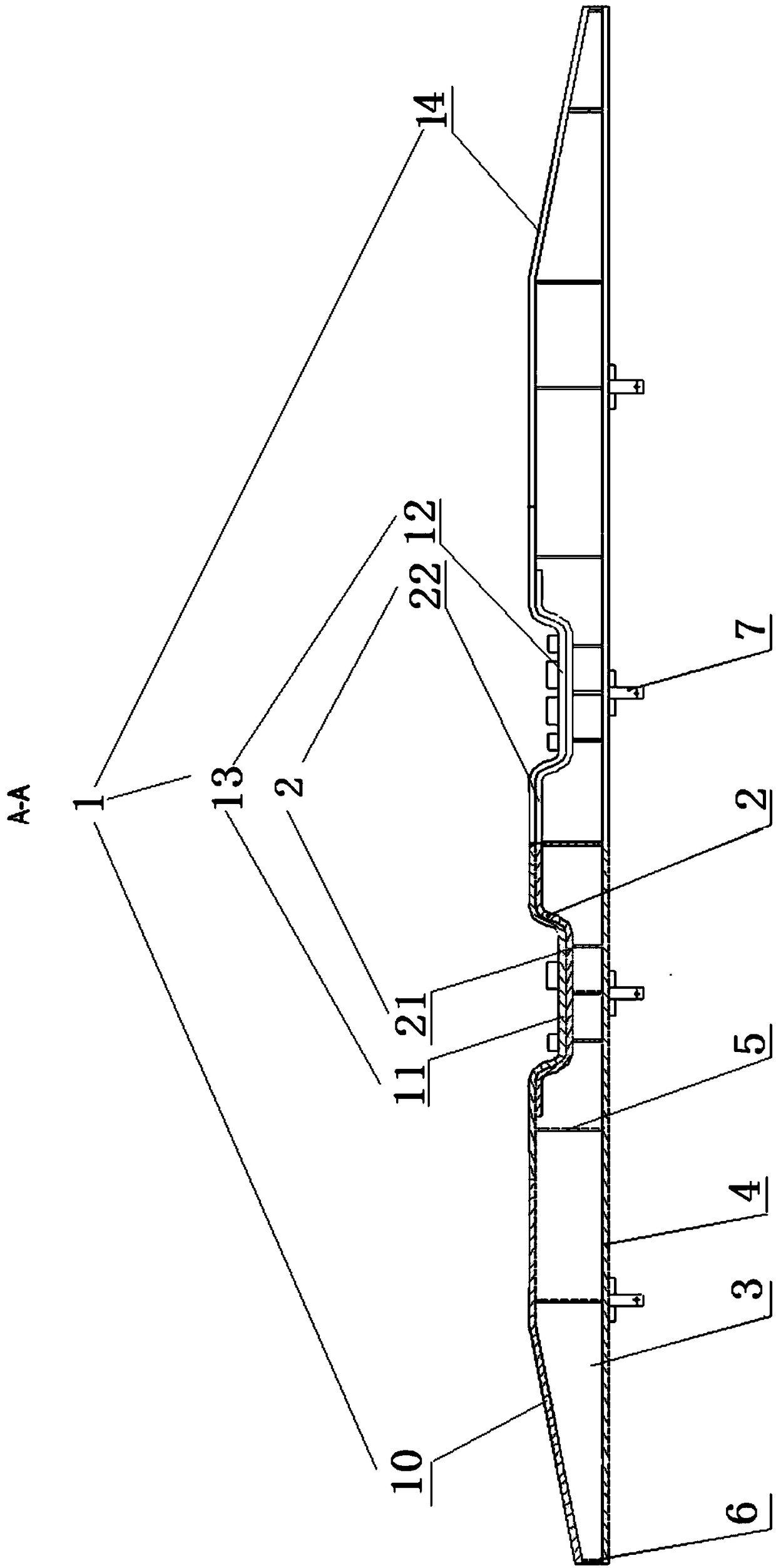

[0041] Such as figure 1 with figure 2 As shown, it is a schematic diagram of the welded side frame structure, which includes an upper cover plate 1, a reinforcing plate 2, a web plate 3, a lower cover plate 4, a partition plate 5, a blocking plate 6 and a pin seat 7.

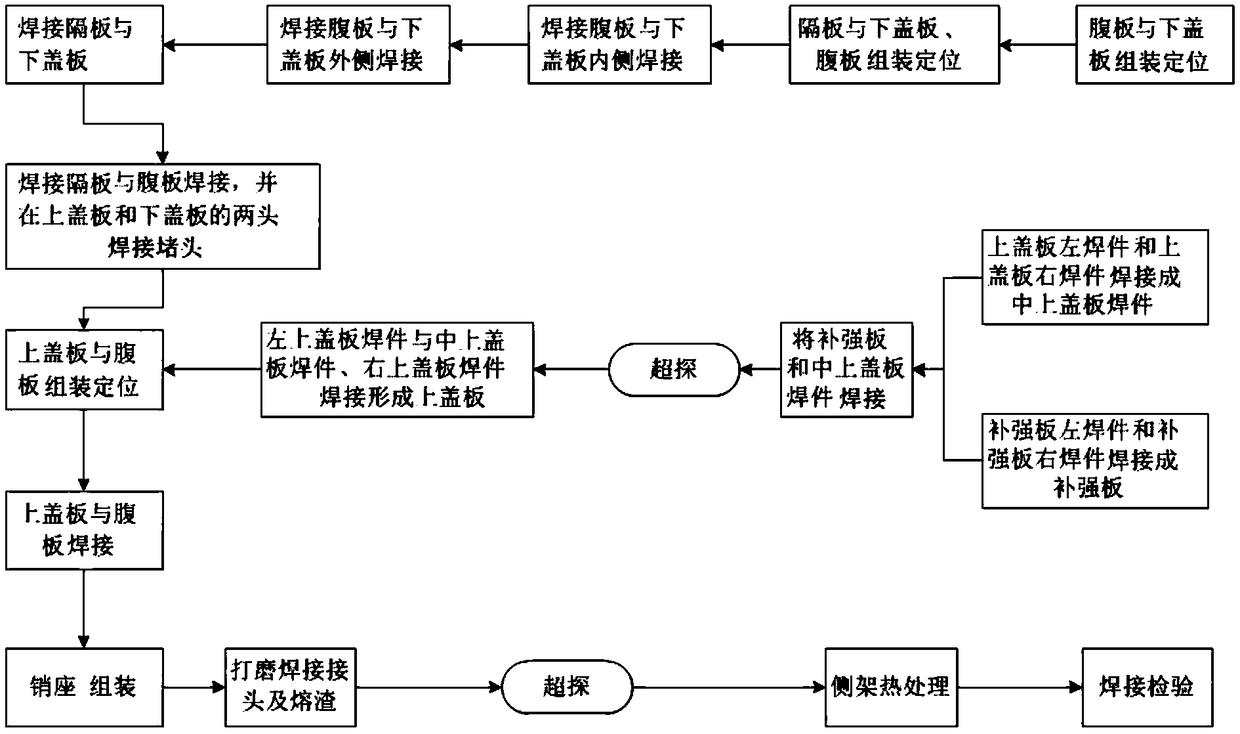

[0042] Such as image 3 As shown, the welding method of a five-axle bogie welding frame side frame for a bridge erecting machine provided by the invention comprises the following steps:

[0043] 1) Weld the upper cover plate left weldment 11 and the upper cover plate right weldment 12 into the upper cover plate weldment 13;

[0044] 2) Weld the left weldment 21 of the reinforcing plate and the right weldment 22 of the reinforcing plate to form the reinforcing plate 2;

[0045] 3) Weld the reinforcing plate 2 welded in the above steps and the weldment 13 of the middle and upper cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com