a welding method

A technology of double-sided welding and welding wire, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of incomplete fusion of welds, and achieve the effect of ensuring full penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

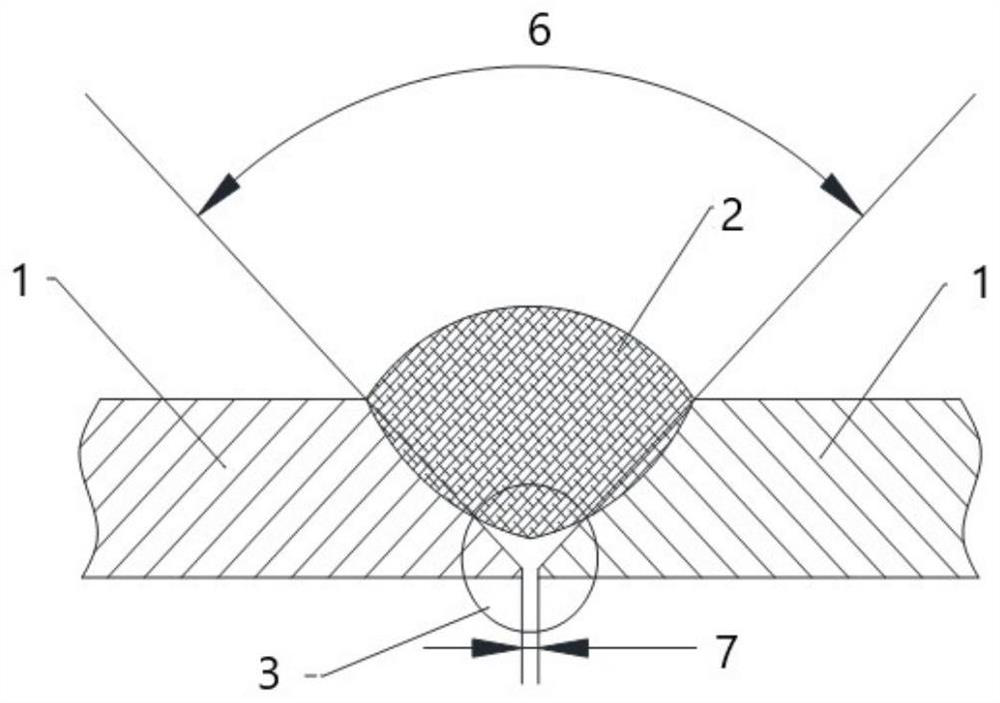

[0035] like figure 2 As shown, a single-sided welding method, the base metal 1 is made of fine-grained structural steel, the plate thickness is 8mm-20mm, the angle of the groove 6 is 30°-50°, and the distance 7 between the front ends of the two base metals 1 is 2- 3mm, the specific steps are as follows:

[0036] S1. Use tungsten inert gas shielded welding to perform back welding on the weld to be welded between the two base metals 1. The welding current for back welding is 120-130A, the voltage is 14-16V, and the welding speed is 1-3mm / s, the shielding gas is Ar99.99%, the shielding gas flow rate is 10-15L / min, and the welding wire with a diameter of 2.2mm is used for root welding to form the root weld 4 of tungsten inert gas shielded welding;

[0037] S2. Use metal gas shielded welding to fill the weld seam after root welding. The welding current of filling welding is 240-260A, the voltage is 26-28V, the welding speed is 4-6mm / s, and the shielding gas is Ar80%+ CO 2 20%,...

Embodiment 2

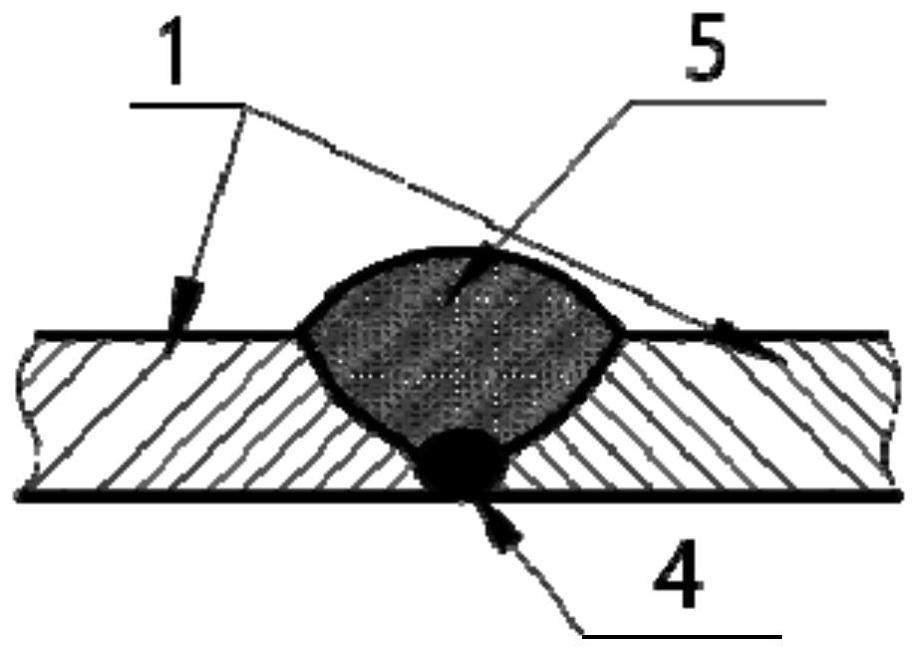

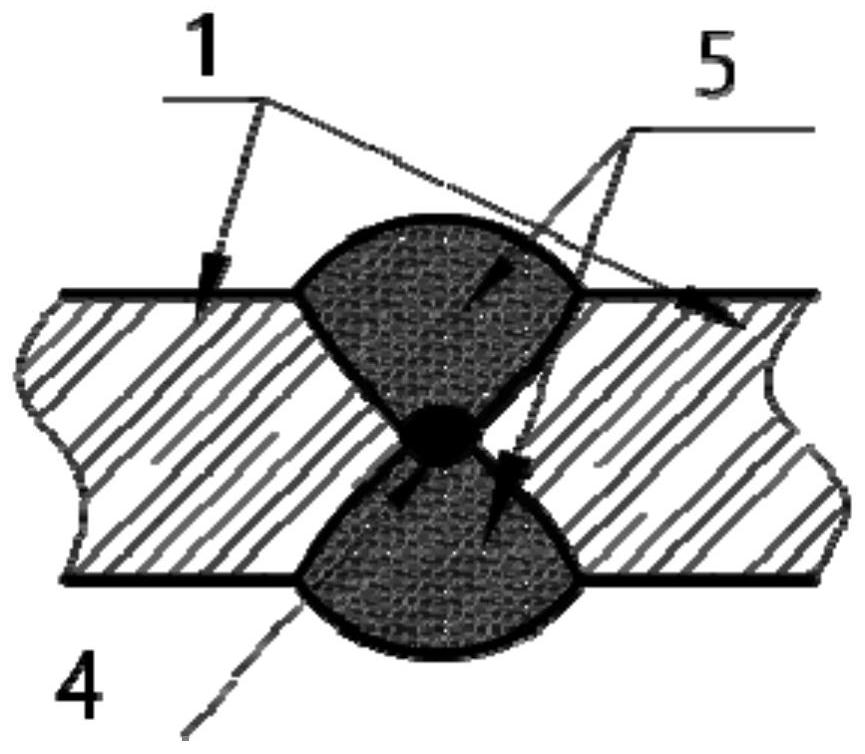

[0042] like image 3 As shown, a double-sided welding method, the base metal 1 is made of fine-grained structural steel, the plate thickness is 8mm-20mm, the angles of the grooves 6 on both sides are 30°-50°, and the distance between the front ends of the two base metals 1 7 is 2-3mm, the specific steps are as follows:

[0043] S1. Use tungsten inert gas shielded welding to perform back welding on the front weld seam between the two base metals. The welding current for back welding is 120-130A, the voltage is 14-16V, and the welding speed is 1-3mm / s, the shielding gas is Ar99.99%, the shielding gas flow rate is 10-15L / min, and the welding wire with a diameter of 2.2mm is used for backing welding;

[0044] S2. Grind the area to be welded on the back, and use tungsten inert gas shielded welding to perform back welding on the back weld between the two base metals. The welding current of the back welding is 120-130A, and the voltage is 14-16V. The welding speed is 1-3mm / s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com