Manufacturing method of through hole structure in PDMS (polydimethylsiloxane) microfluidic device

A technology of a microfluidic device and a manufacturing method, which is applied in the directions of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of increasing the complexity of the manufacturing process and the manufacturing cost, and achieves low cost, wide selection range, and manufacturing. Ease of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

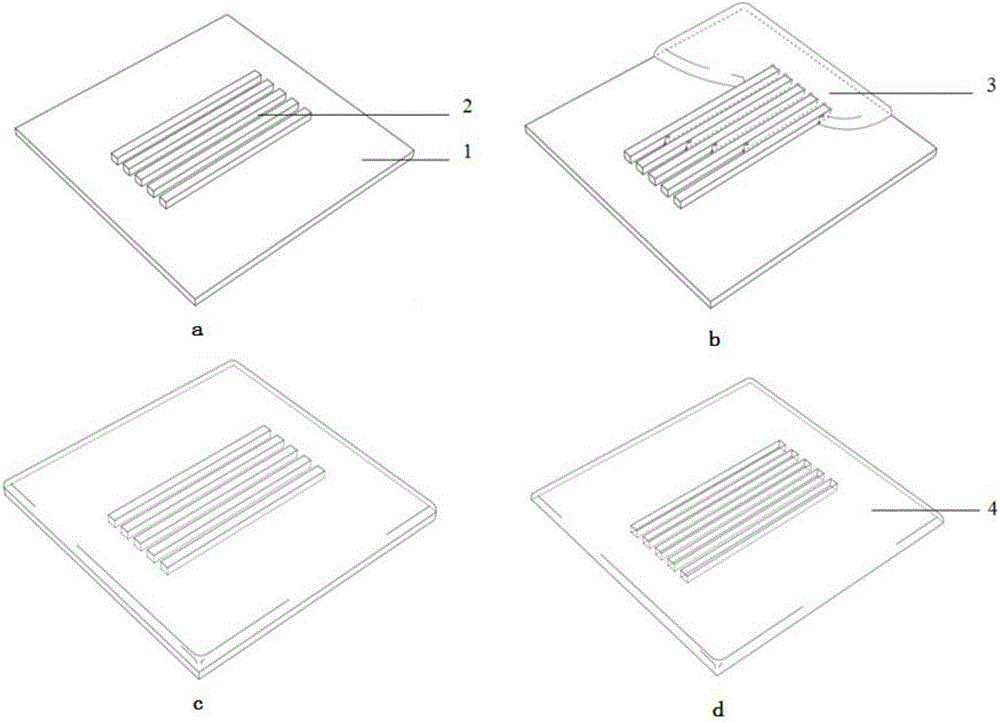

[0021] like figure 1 Shown, the fabrication method of the elongated through hole in the PDMS microfluidic device of the present invention, comprises the following steps:

[0022] 1) if figure 1 As shown in a, a mold 1 is produced, and the mold 1 contains a plurality of elongated protrusions 2 corresponding to the through holes to be manufactured, and each elongated protrusion 2 is distributed in parallel, with a width of 100 μm and a height of 100 μm. The distance between each elongated protrusion 2 is 100 μm.

[0023] 2) if figure 1 As shown in b, the mold 1 is placed horizontally, and the PDMS prepolymer 3 is slowly injected from the side of the mold 1 using a syringe or other liquid injection tools. The PDMS prepolymer 3 is composed of PDMS monomer and curing agent with a mass ratio of 10:1 mixed. The PDMS prepolymer 3 gradually wets the surface of the mold 1 and extends along the gaps between the elongated protrusions 2 under the action of capillary force. Due to the ...

Embodiment 2

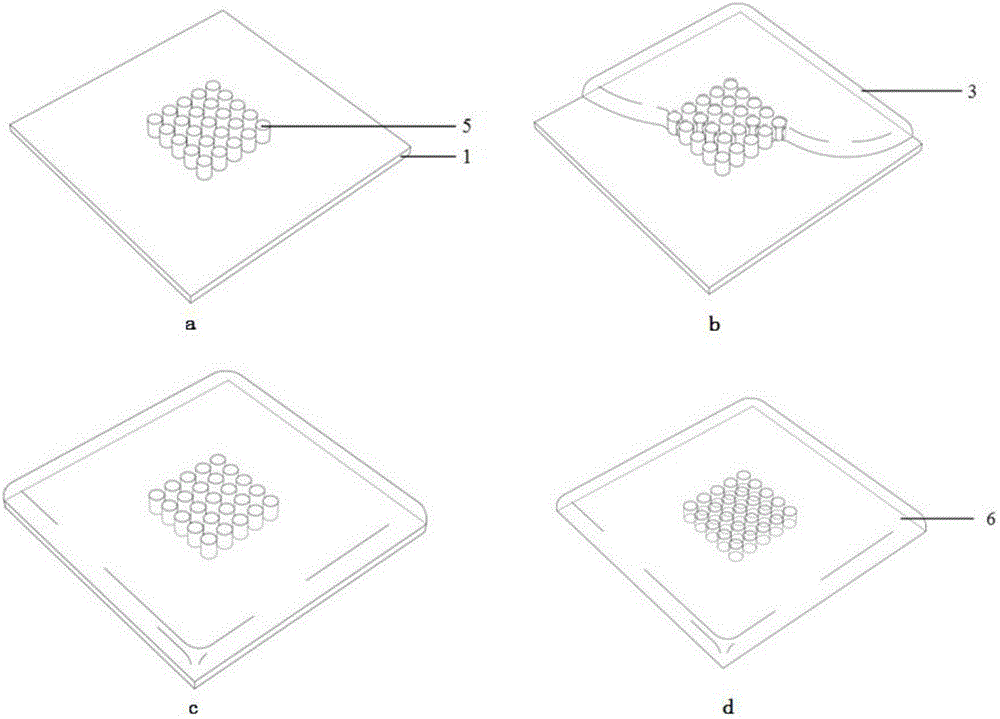

[0028] like figure 2 Shown, the fabrication method of highly integrated cylindrical through hole in the PDMS microfluidic device of the present invention, comprises the following steps:

[0029] 1) if figure 2 As shown in a, at first the mold 1 is made, and the mold 1 contains cylindrical protrusions 5 corresponding to the required through-holes, and each cylindrical protrusion 5 is vertically arranged in a matrix, and the diameter of each cylindrical protrusion 5 is 150 μm, the height is 200 μm, and the minimum distance between two adjacent cylindrical protrusions 5 is 50 μm.

[0030] 2) if figure 2 As shown in b, place the mold 1 horizontally, slowly inject PDMS prepolymer 3 from one side of the mold 1; Gap extension.

[0031] 3) if figure 2 As shown in c, after the PDMS prepolymer 3 fills the gaps of the cylindrical bosses 5 , a proper amount of PDMS prepolymer 3 is added to the edge of the mold so that the liquid level is flush with the upper surface of the cylind...

Embodiment 3

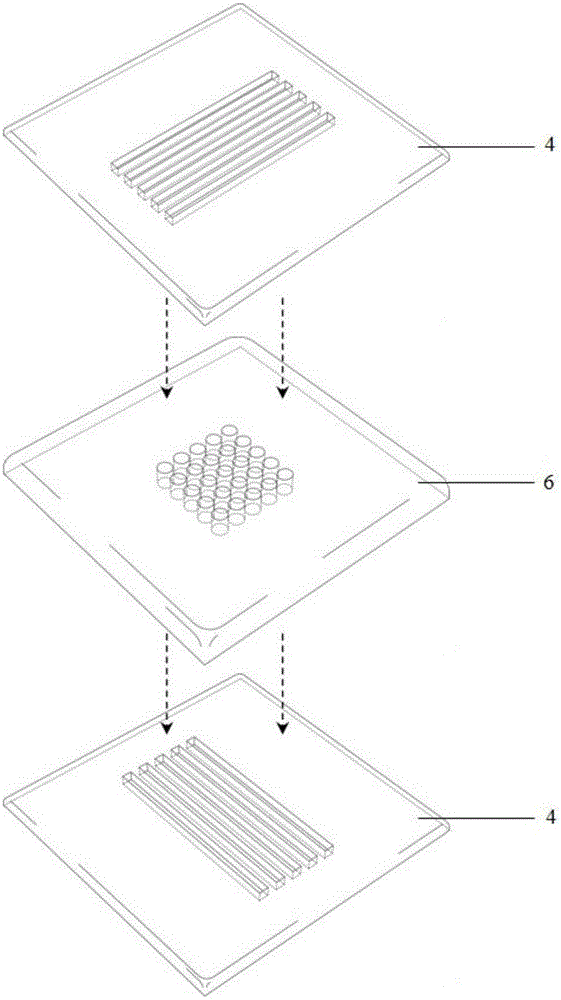

[0037] The invention can make a through-hole structure connecting different microchannel layers in the PDMS microfluidic device, and further constitute a device containing multilayer channels. like image 3 As shown, two PDMS through-hole layers 4 made by embodiment 1 are respectively used as an upper microchannel layer and a lower microchannel layer, and the PDMS through-hole layer 6 made by embodiment 2 is used as an intermediate layer. The three-layer structure is aligned and bonded twice, that is, it is made into a two-layer microchannel structure connected up and down, wherein the cylindrical through-hole in the PDMS through-hole layer 6 plays a role in connecting the upper and lower two-layer microchannels. Above and below the two-layer microchannel structure, if other PDMS layers or glass layers are bonded, complex microfluidic devices containing more layers of microchannel structures can also be fabricated.

[0038] Summing up the above-mentioned embodiments, it can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com