Crane beam manufacturing method

A manufacturing method and technology for driving beams, which are applied in the directions of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems such as the inability to use the production process of driving beams, and achieve clear production operations, scientific methods, and avoid the risk of missed inspections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

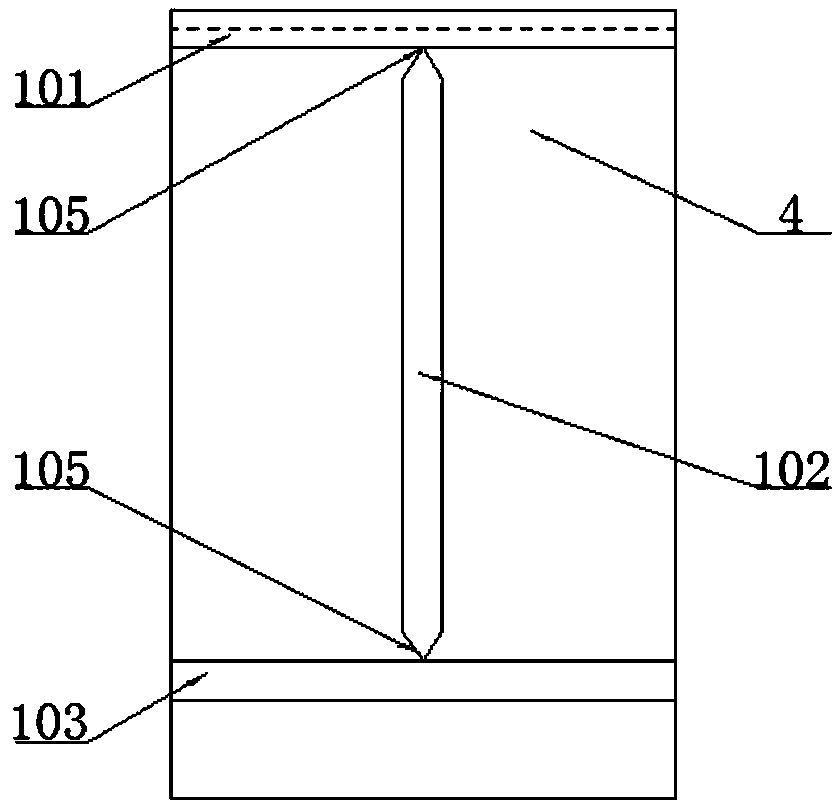

[0020] Such as Figure 1-4 Described, is a kind of manufacturing method of driving beam, comprises the following steps:

[0021] Step 1: Screening of raw materials, selecting long slabs with a thickness of 15-25 mm for the production of the upper flange 101, web 102 and lower flange 103 of the H-shaped steel beam 1, ensuring the flatness error of each long slab Within ±2mm;

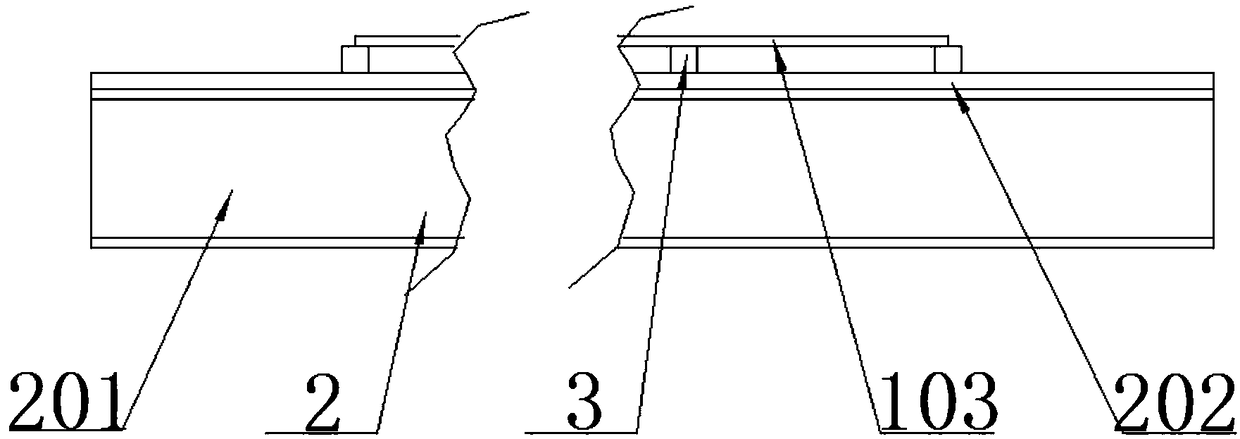

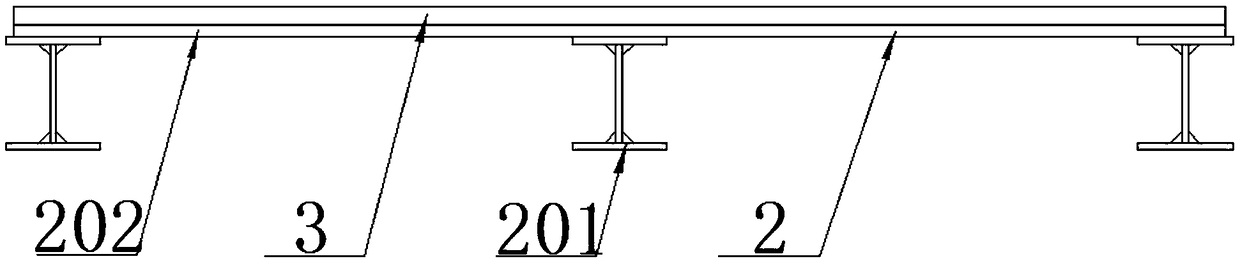

[0022] Step 2: Manufacture the tire frame 2. Lay multiple I-beams 201 in the same direction at equal intervals and fix them on the ground. The lower plate of the I-beam 201 is in contact with the ground, and the upper plate is suspended in the air and set horizontally. The levelness of multiple points on the upper plate of the steel 201 ensures that each I-beam 201 is set horizontally, and then hoists a flat plate with a thickness of 20-30mm on each I-beam 201 to form a sealing plate 202 to ensure that each sealing plate 202 The gap between the lower surface and the upper surface of each I-beam 201 is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com