Clamp and machining equipment

A fixture and cylinder technology, applied in the field of fixtures and processing equipment, can solve the problems of insufficient machining accuracy of rod-shaped parts, and achieve the effect of solving insufficient machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

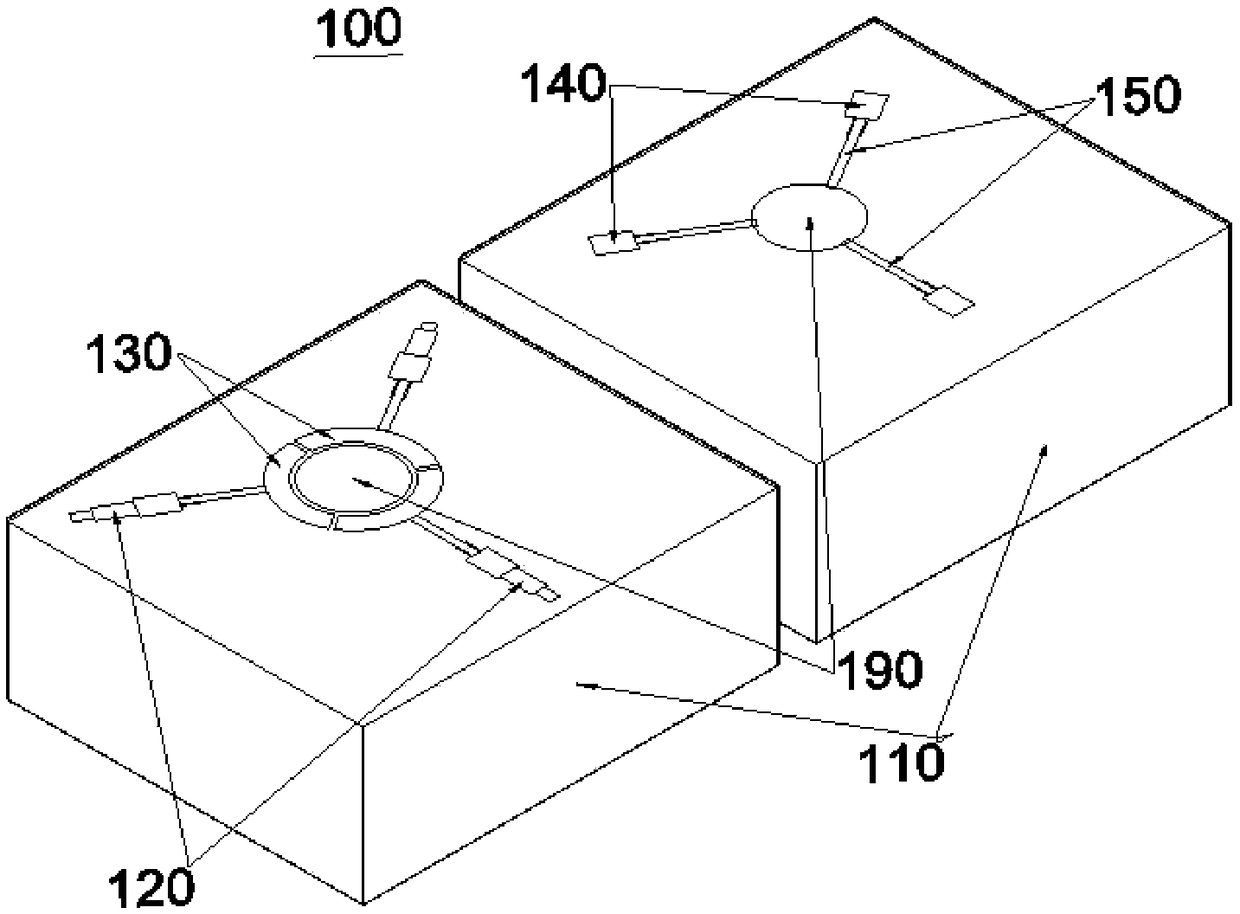

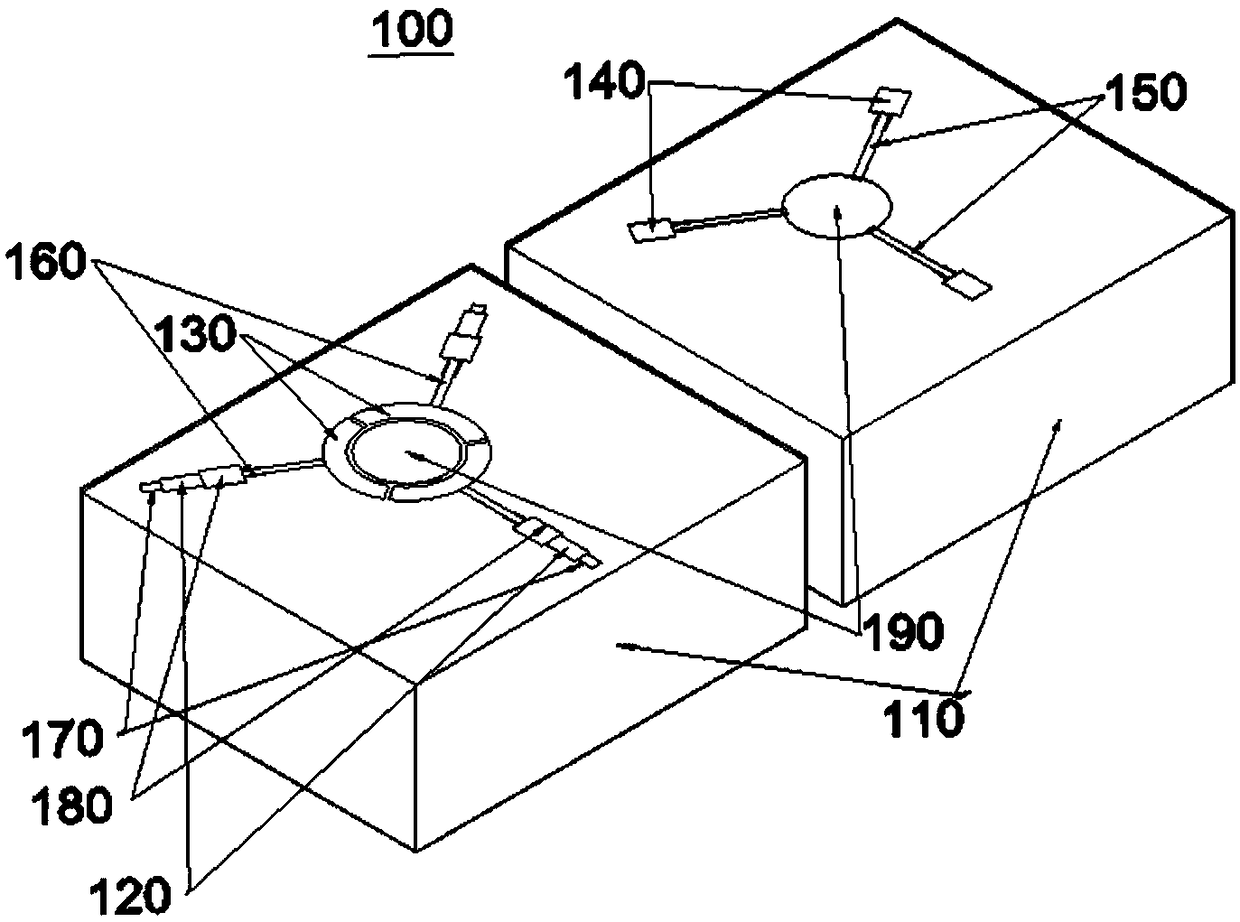

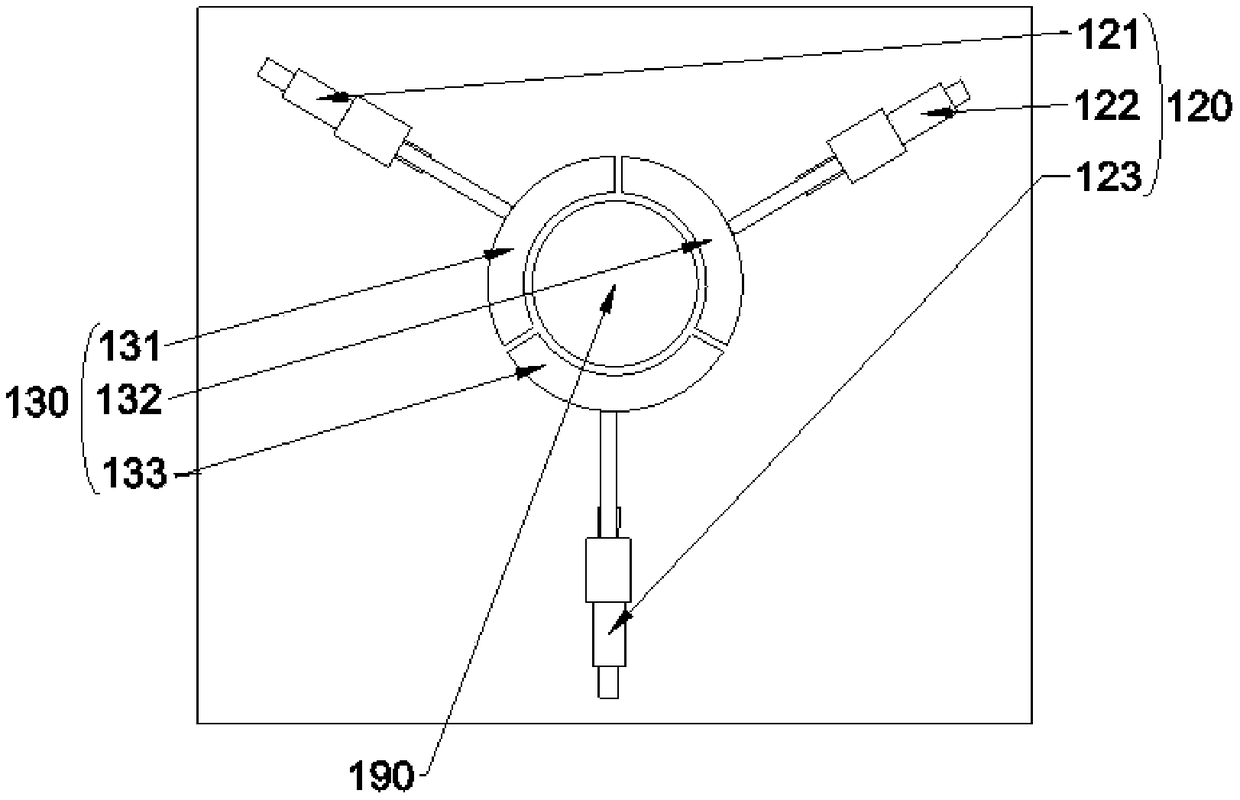

[0032] See figure 1 , figure 1 It shows the front and back first view structural schematic diagrams of the clamp provided by the embodiment of the present application. A clamp 100 provided by the application of the present invention, the clamp 100 includes: a housing 110, a plurality of fixed driving cylinders 120, a plurality of fixed blocks 130, a plurality of positioning driving cylinders 140 and a plurality of positioning rods 150; a plurality of fixed driving cylinders The number of 120 is the same as the number of a plurality of fixing holes, the number of a plurality of positioning drive cylinders 140 is the same as the number of a plurality of positioning rods 150; the housing 110 is provided with a fixing through hole 190, and the fixing through hole 190 runs through the housing 110. A fixed drive cylinder 120 is movably connected with a plurality of fixed blocks 130, a plurality of fixed blocks 130 are arranged around the fixed through hole 190 and a plurality of fi...

no. 2 example

[0051] See Figure 6 , Figure 6 A schematic structural diagram of the processing equipment provided by the embodiment of the present application is shown. The present application also provides a processing device 101 , the processing device 101 includes a processing device body, and the processing device body includes the above clamp 100 .

[0052] Wherein, it should be noted that the processing equipment 101 includes a processing equipment body, and the processing equipment body includes the clamp 100 as above.

[0053] The application of the present invention provides a fixture and processing equipment. A plurality of fixing blocks are arranged around the fixing through hole and the plurality of fixing blocks evenly surround the fixing through hole, and a plurality of positioning rods are arranged around the fixing through hole and the plurality of positioning rods are uniform Surround the fixed vias. In the case of a plurality of fixed blocks driven by the fixed driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com