Cutting machine for heat-insulation plate

A technology of plate cutting machine and heat preservation plate, applied in metal processing and other directions, can solve the problems of reducing production efficiency, failing to meet quality requirements, unevenness, etc., and achieving the effect of increasing contact area, strong practicability, and avoiding sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 (cutting in the width direction)

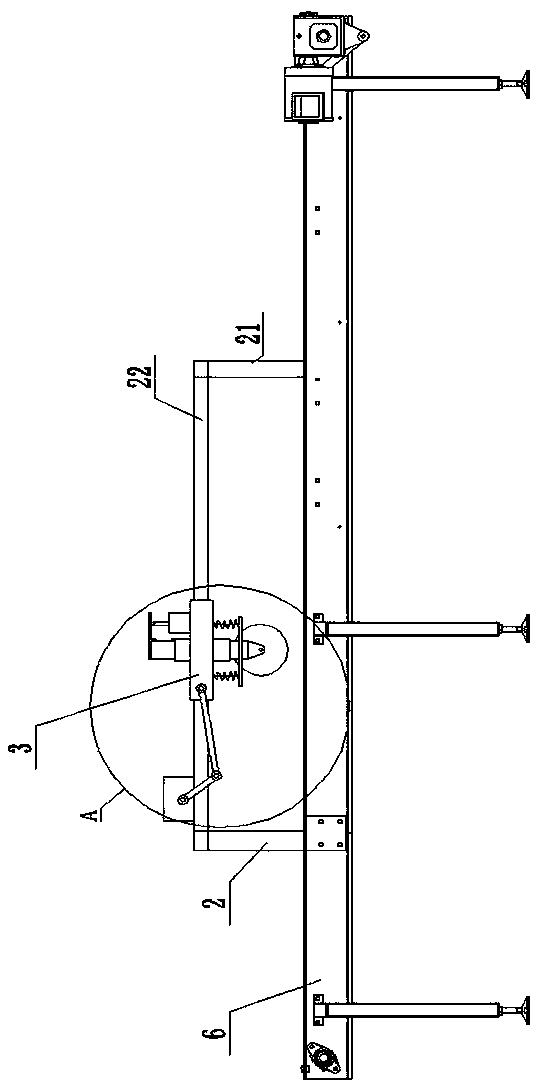

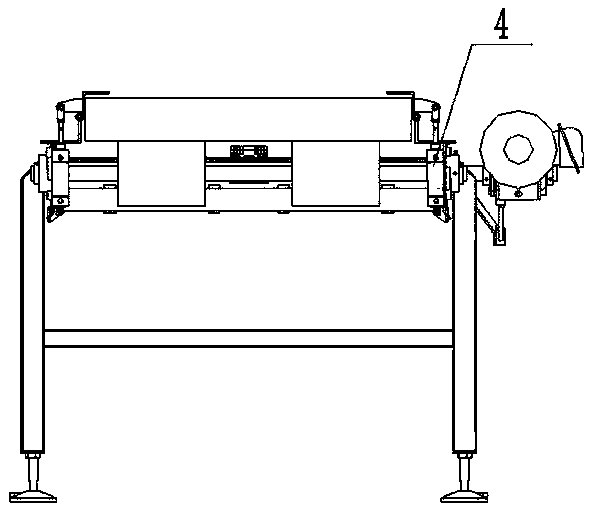

[0046] as attached figure 1 As shown, a thermal insulation board cutting machine of the present invention includes a frame 6 for fixing the whole machine and placing the thermal insulation board 5, the frame 6 is provided with a transmission track 1, and the top of the transmission track 1 is erected on the frame 6 There is a support 2 on which a cutting device 3 for cutting the insulation board 5 is installed.

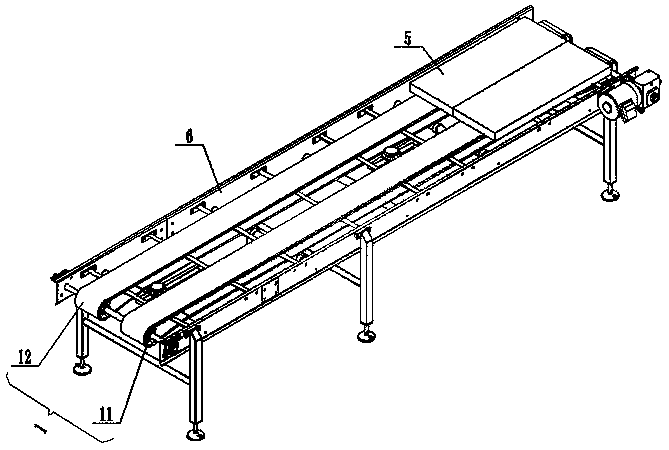

[0047] combined with image 3 , the transmission track 1 is existing, and is connected to form by a plurality of driving rollers 11 that are arranged along the width direction of the frame 6, and the driving rollers 11 are used to support the insulation board 5, and the transmission rollers 11 are driven by a transmission motor to make the insulation board 5 along the transmission Track 1 moves along its length. It is also possible to assemble a conveyor belt 12 on the drive roller 11, the conveyor belt 12 can inc...

Embodiment 2

[0060] Example 2 (cutting in the length direction)

[0061] as attached Image 6 As shown, a thermal insulation board cutting machine of the present invention includes a frame 6 for fixing the whole machine and placing the thermal insulation board 5, the frame 6 is provided with a transmission track 1, and the top of the transmission track 1 is erected on the frame 6 There is a support 2 on which a cutting device 3 for cutting the insulation board 5 is installed.

[0062] combined with Figure 7 , the transmission track 1 is existing, and is connected to form by a plurality of driving rollers 11 that are arranged along the width direction of the frame 6, and the driving rollers 11 are used to support the insulation board 5, and the transmission rollers 11 are driven by a transmission motor to make the insulation board 5 along the transmission Track 1 moves along its length. It is also possible to assemble a conveyor belt 12 on the drive roller 11, the conveyor belt 12 can i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com