Preparation device for double-need-bar full-fashioned 3D bionic hair product

A preparation device and fully formed technology, which is applied in wigs, knitting, warp knitting, etc., can solve the problems that the bar device cannot move forward and backward, and the warp knitting machine has a single function, so as to achieve good wearability, excellent air permeability, and satisfy The effect of the wig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

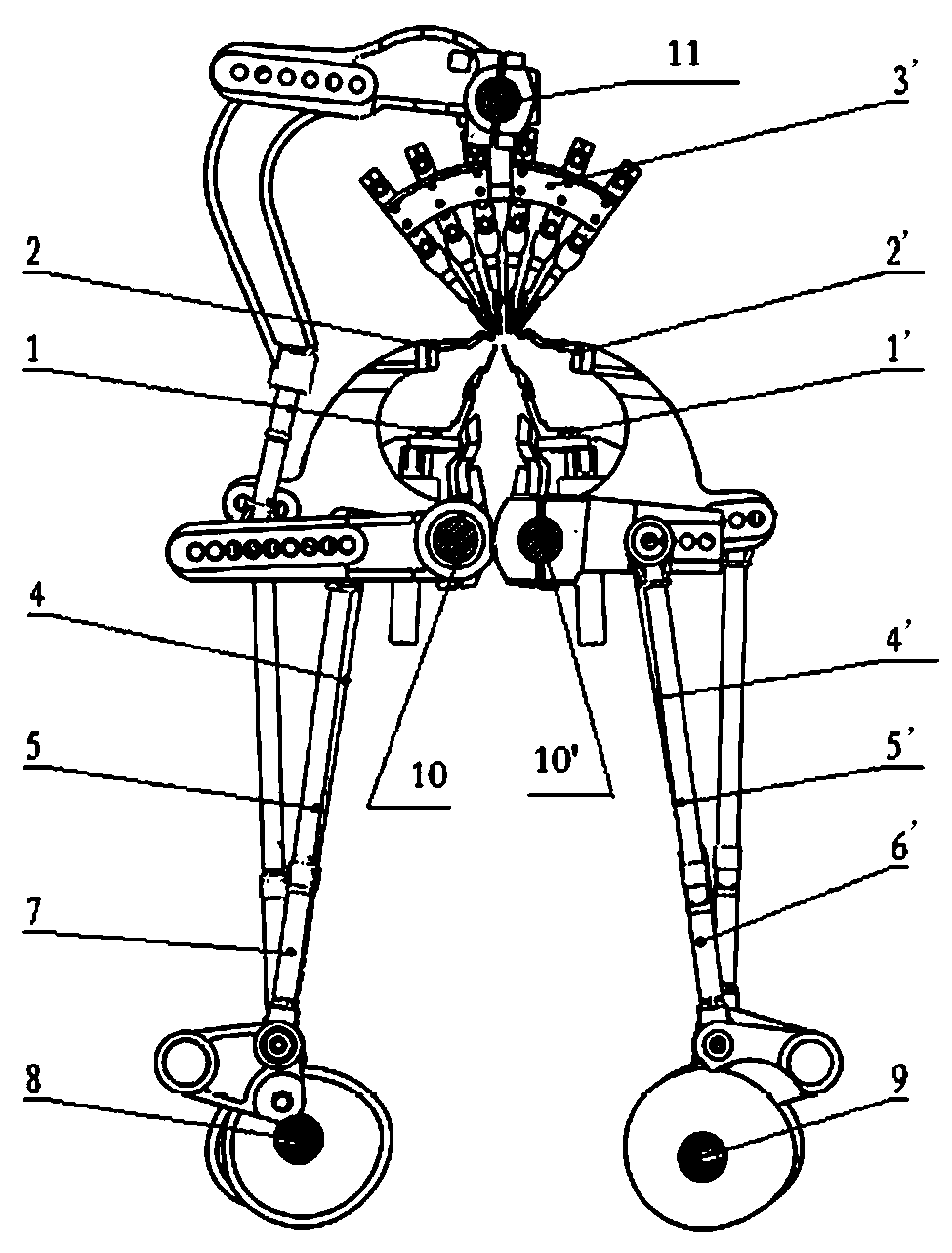

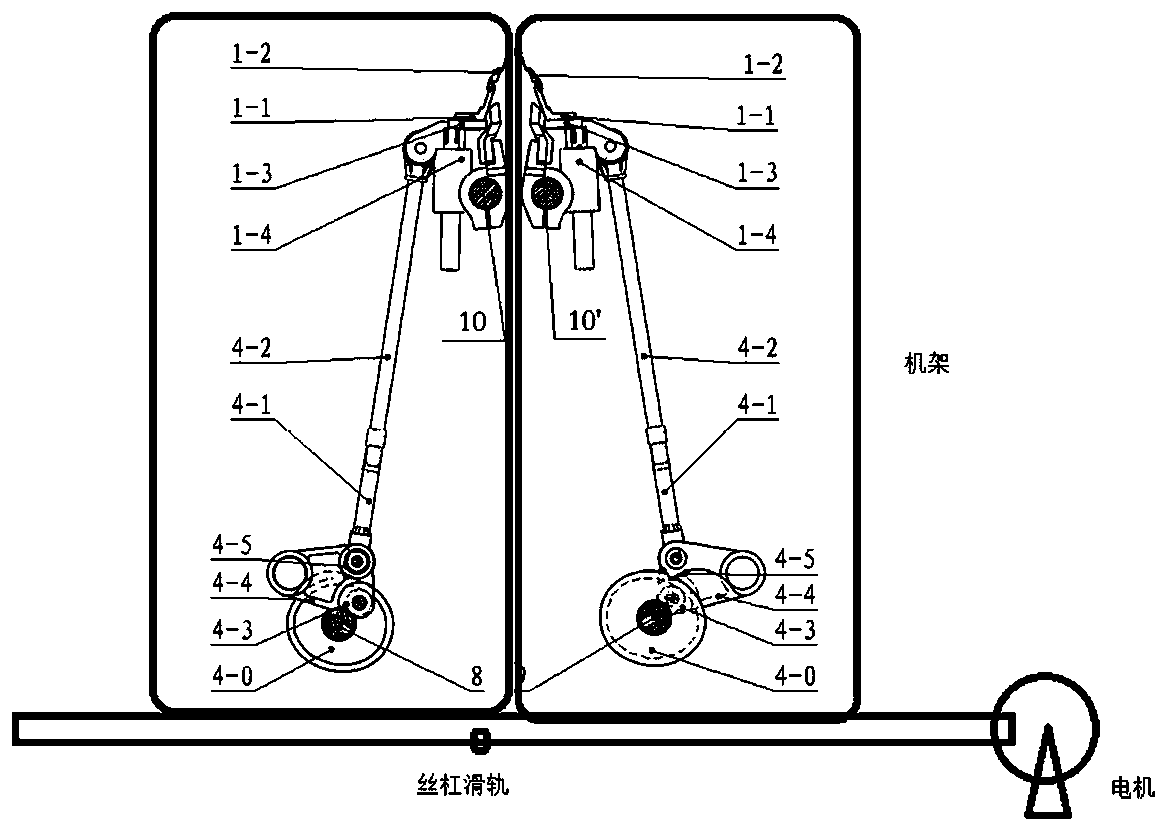

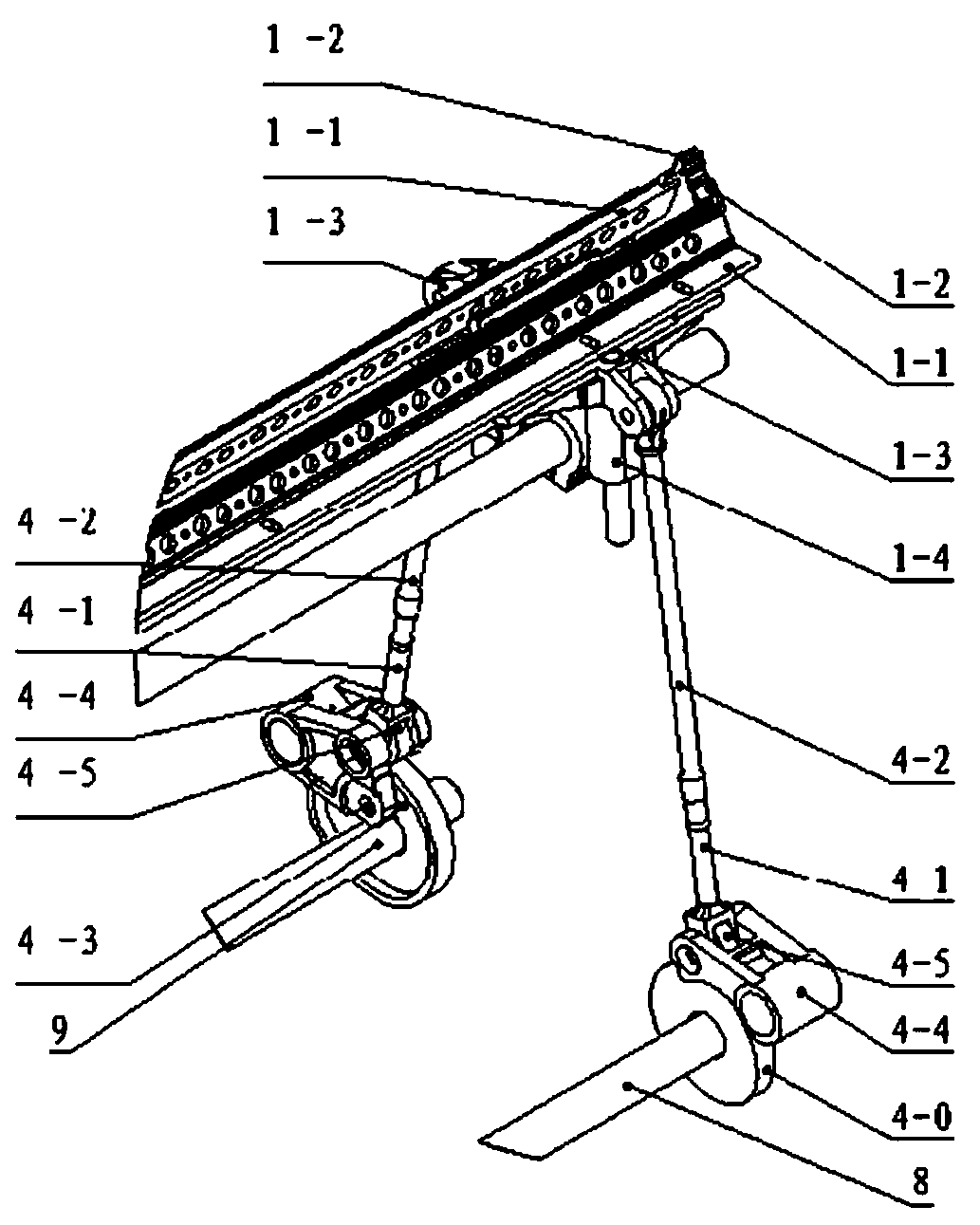

[0034] A preparation device for fully formed 3D bionic hair products with double needle beds, including front and rear frames, a hair bionic fixed-length cutting device, and a frame moving device, which includes a motor, a lead screw and a lead screw slide rail , the frame is provided with a knitting device and a comb device 3, the comb device 3 is arranged on the frame through the upper swing shaft 11, and the knitting device includes a front needle bed 1, a rear needle bed 1', a front settlement The sheet bed 2 and the rear sinker bed 2', the front needle bed 1 and the rear needle bed 1' are symmetrically arranged on the frame through the front swing shaft 10 and the rear swing shaft 10' respectively, the front sinker bed 2, the rear The sinker bed 2' is also symmetrically arranged on the frame through the front pendulum shaft 10 and the rear pendulum shaft 10' respectively, and a transmission device is arranged on the frame below the front pendulum shaft 10 and the rear pend...

Embodiment 2

[0045] A preparation device for double-needle bed fully formed 3D bionic hair products. The specific structure is shown in Example 1. The hair bionic fixed-length cutting device intelligently adjusts the movement of the frame on the slide rail according to the fashion trend and customer needs to ensure the length of each comb. Changes to meet customer needs and remotely customize orders for 45cm long wig hair pieces. The motor drives the lead screw to rotate, and the front and rear racks are adjusted to adjust the distance along the lead screw slide rail. The knitting motion of each part in the loop forming device is driven by each transmission mechanism in the transmission device. Knitting device and combing device on the front and rear frame, transmission device on the frame under the front and rear swing shafts (the transmission device includes the front needle bed transmission mechanism, the rear needle bed transmission mechanism, the front sinker bed transmission mechanis...

Embodiment 3

[0047] A preparation device for double-needle bed fully formed 3D bionic hair products. The specific structure is shown in Example 1. The hair bionic fixed-length cutting device intelligently adjusts the movement of the frame on the slide rail according to the fashion trend and customer needs to ensure the length of each comb. Variations to meet customer needs and remotely customize orders for 15cm long fake beards. The motor drives the lead screw to rotate, and the front and rear racks are adjusted to adjust the distance along the lead screw slide rail. The knitting motion of each part in the knitting device is driven synchronously by each transmission mechanism in the transmission device. Knitting device and combing device on the front and rear frame, transmission device on the frame under the front and rear swing shafts (the transmission device includes the front needle bed transmission mechanism, the rear needle bed transmission mechanism, the front sinker bed transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com