A cam type multi-stage compression miniature high-pressure air pump

A high-pressure air pump, cam type technology, used in multi-stage pumps, variable displacement pump components, pumps, etc., can solve the problems of large volume, unfavorable miniaturization and integration, achieve small volume and weight, reduce equipment volume and accessories The use of, the effect of reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

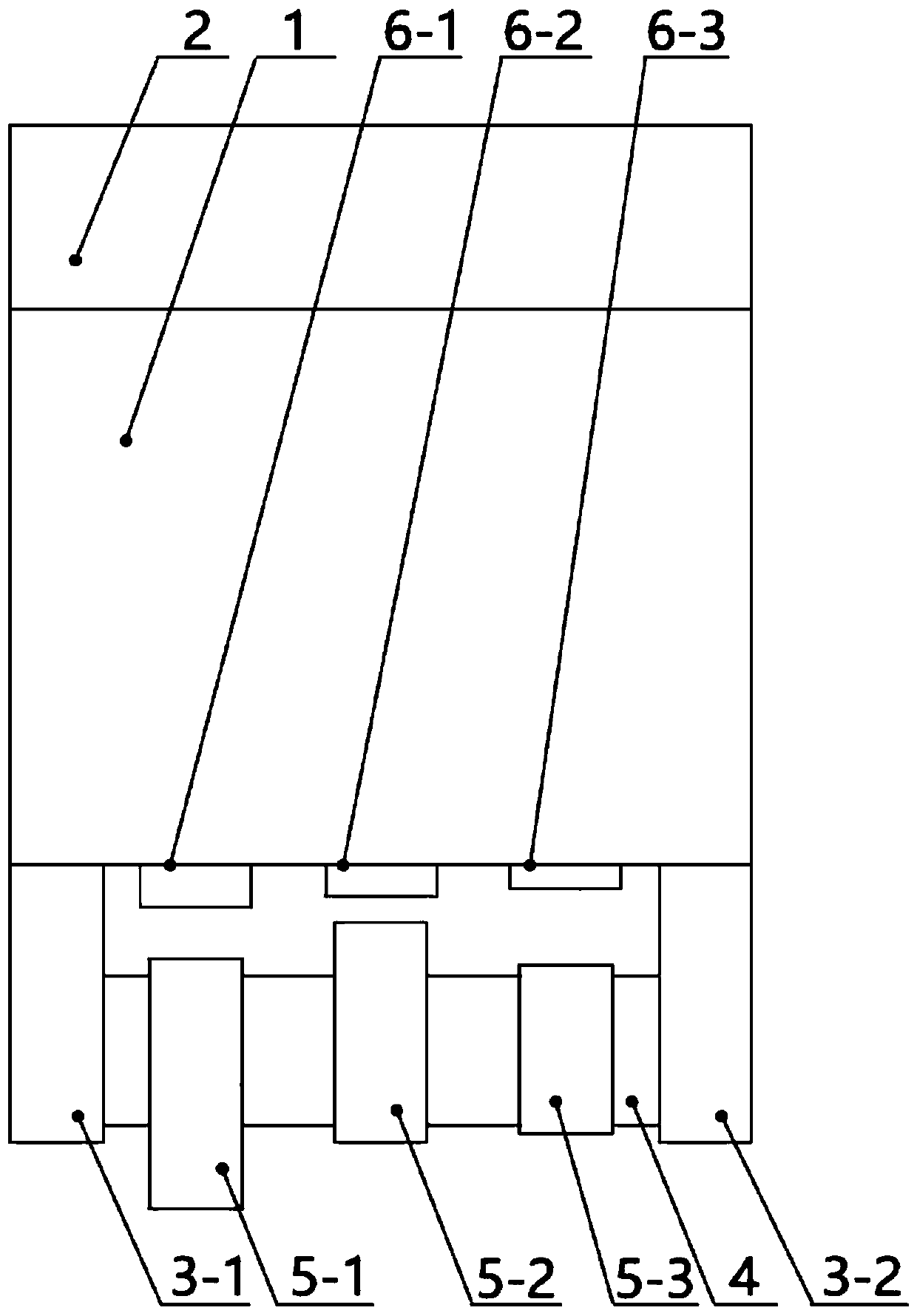

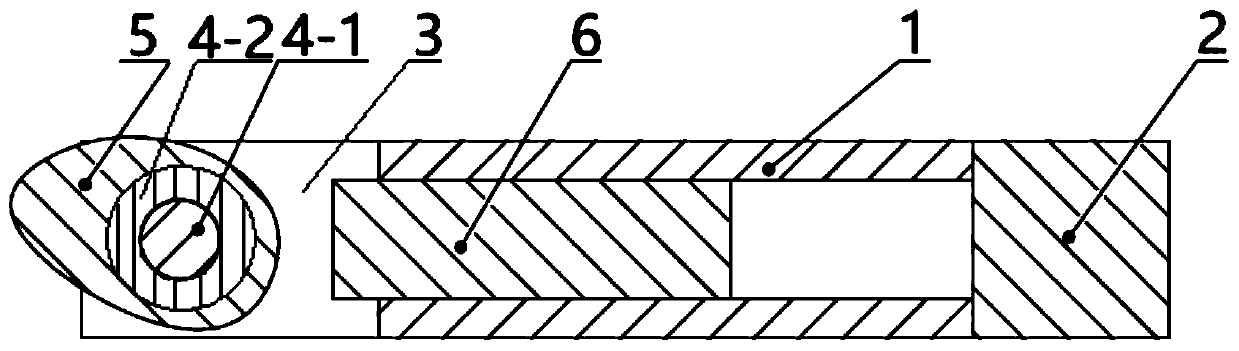

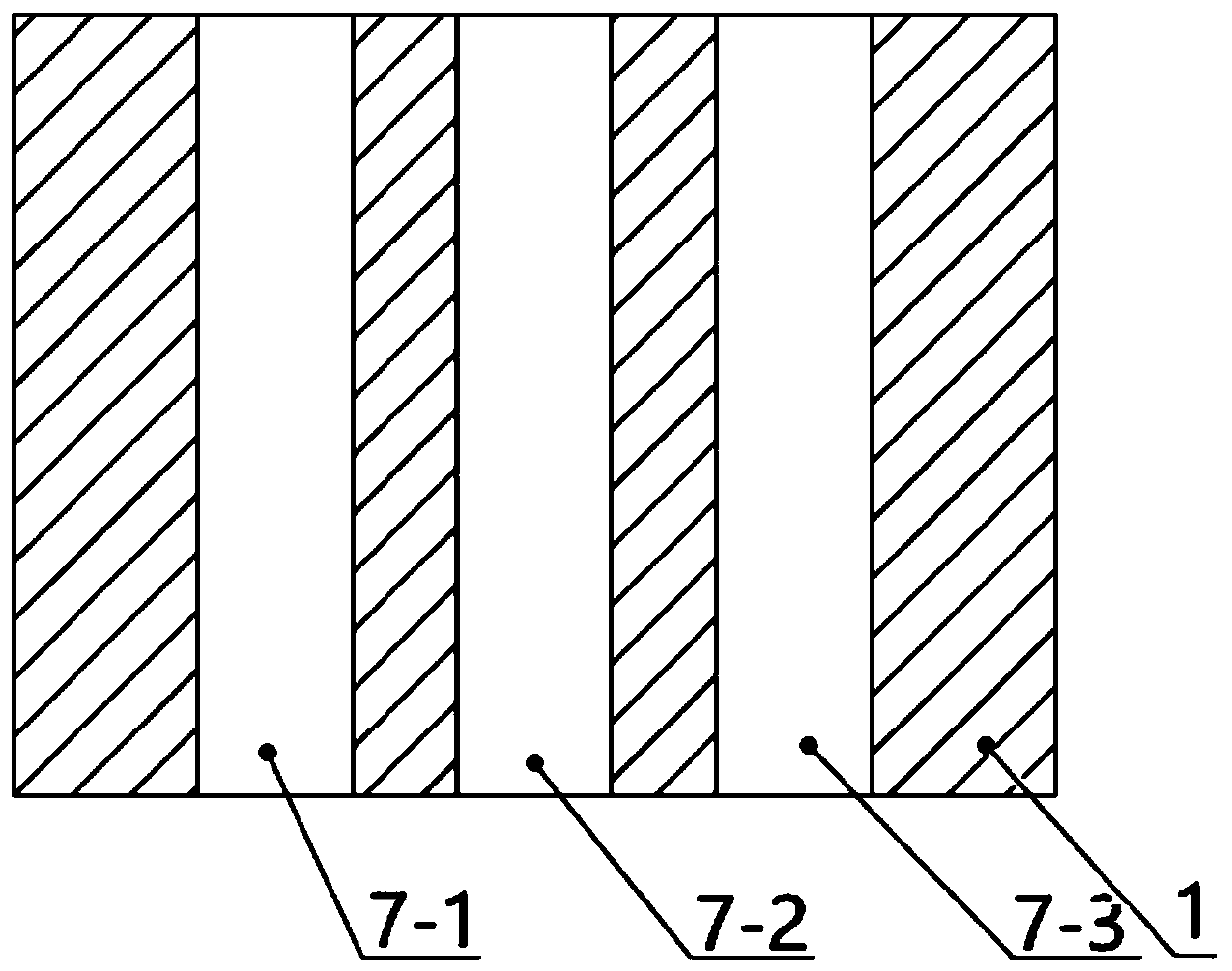

[0025] Such as figure 1 Shown is a cam-type multi-stage compression miniature high-pressure air pump, including a cylinder body 1, a rear end cover 2, a motor bracket 3, a motor 4, a cam 5 and a compression plunger 6; the motor 4 includes a motor stator 4-1 and an electric motor Sub 4-2, the two ends of the motor stator 4-1 are kept fixed with the cylinder body 1 through the motor bracket 3, the motor mover 4-2 is set on the outside of the motor stator 4-1, and the cam 5 is set on the motor mover 4 -2 and keep fixed with the motor mover 4-2, the side of the cylinder body 1 facing the cam 5 is provided with a compression cavity 7, the compression plunger 6 is installed in the compression cavity 7, the rear end cover 2 and the cylinder The body 1 is fixed, and the compression cavity 7 is sealed by the rear end cover 2. The cam 5 corresponds to the compression plunger 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com