Height-adjustable support mechanism and integrated cooker

A support mechanism and height technology, applied in the field of cookers, can solve the problems of difficult movement of target equipment, inconvenient operation, and inconvenient operation, and achieve the effects of easy moving and later maintenance, simple height adjustment, and improved user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

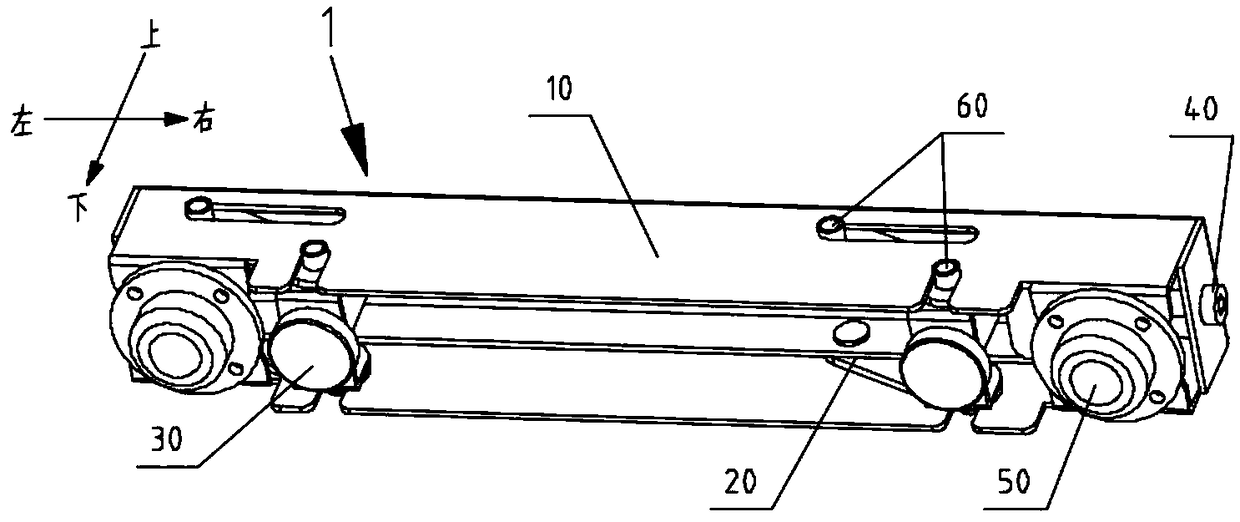

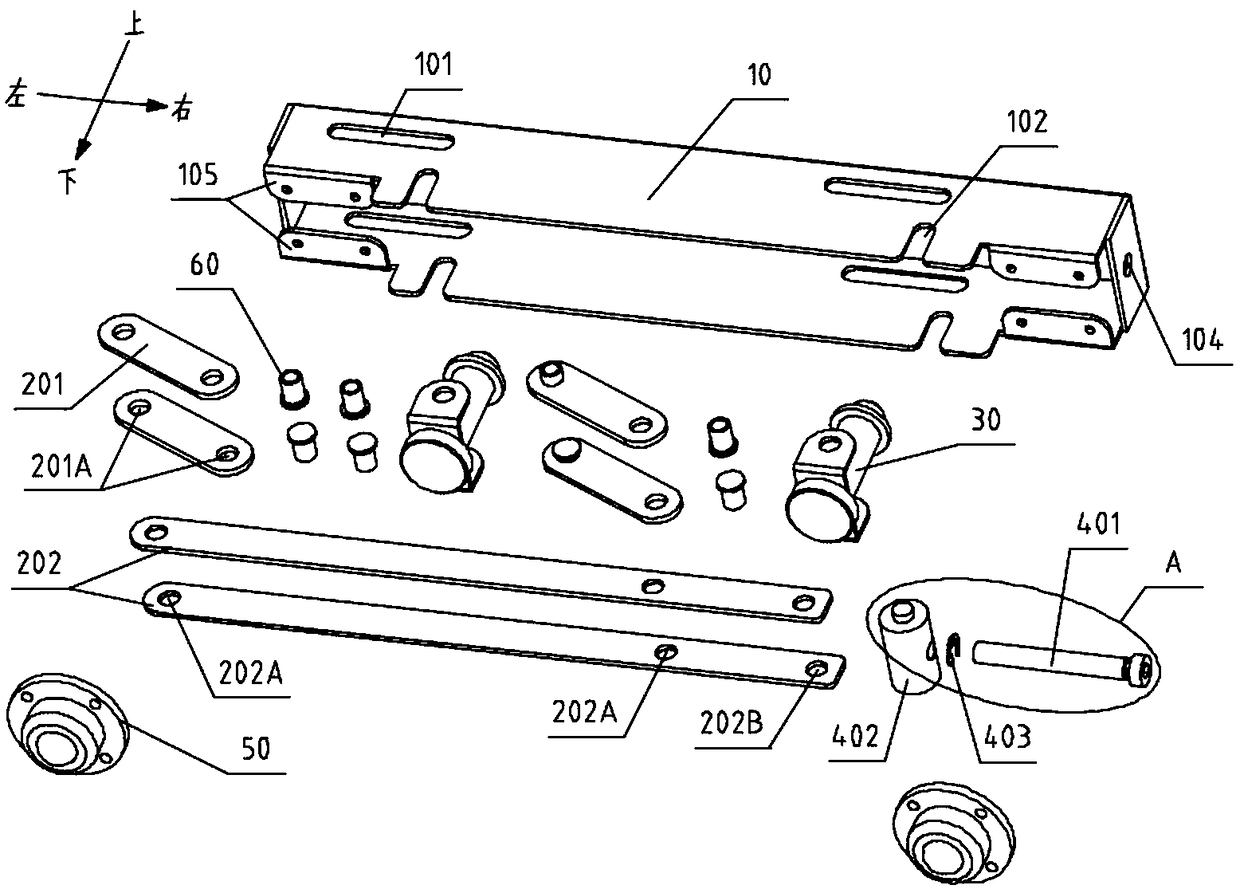

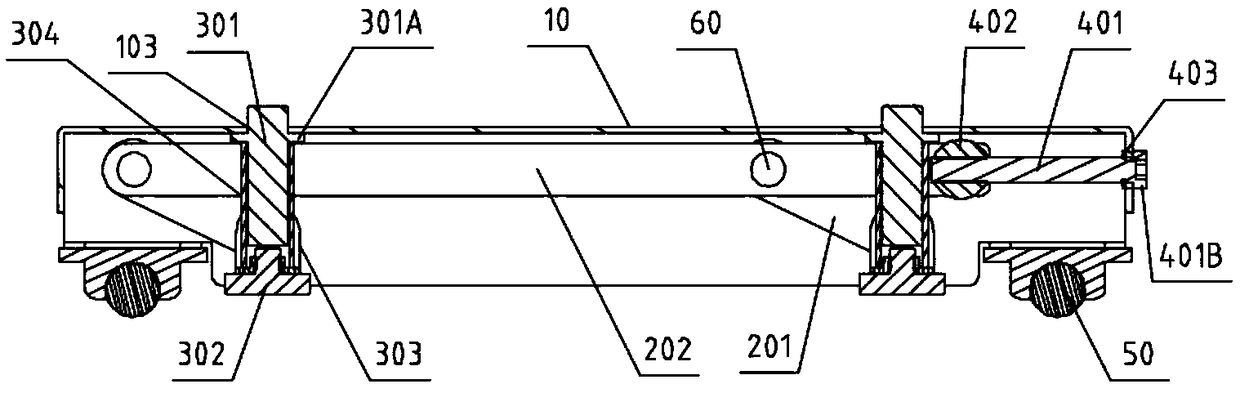

[0032] see figure 1 , a height-adjustable support mechanism of this embodiment, the support mechanism 1 includes a bracket 10 , a transmission assembly 20 , two sets of support assemblies 30 , an adjustment assembly 40 , two sets of moving assemblies 50 and several connectors 60 . The transmission assembly 20 is movably arranged in the bracket 10 and is respectively connected with two sets of support assemblies 30 and adjustment assemblies 40 , the two sets of support assemblies 30 are arranged on both sides of the inside of the bracket 10 so as to be movable up and down, and the adjustment assembly 40 is movably arranged in the bracket 10 , two sets of moving assemblies 50 are respectively installed on both sides of the bottom of the support 10, so that the support 10 can move on the ground. Thus, by driving the adjustment assembly 40 to move, the transmission assembly 20 can synchronously drive the movement of the two sets of support assemblies 30, and then drive the up and ...

Embodiment 2

[0052] Referring to 7-10, an integrated stove in this embodiment includes a main body 2, a base 3, a skirting panel 4 and an oil box 5, the base 3 is arranged at the bottom of the main body 2, and the skirting panel 4 and the oil box 5 are respectively arranged on The base 3 also includes two sets of support mechanisms 1 as described in Embodiment 1, and the two sets of support mechanisms 1 are respectively fixed on opposite sides of the base 3 in parallel. Thus, through the support mechanism 1, the movement of the integrated cooker is quick, fast, convenient, and highly safe, and the danger of the integrated cooker being easily toppled during the moving process or being crushed on people's feet during the process of lifting the equipment and putting it down is avoided. ;At the same time, the overall height adjustment method of the integrated stove is simple, reliable and humanized, and a single person can independently complete the height adjustment of the integrated stove, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com