A device for detecting the filtering effect of an engine filter element and its application method

A filtering effect and engine technology, applied in jet engine testing, gas turbine engine testing, etc., can solve the problems of inaccurate liquid level filling position time, absence of filter element, inaccurate start timing, etc., to achieve detection time and filling end time. Accurate, stable and reliable use method and process, and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

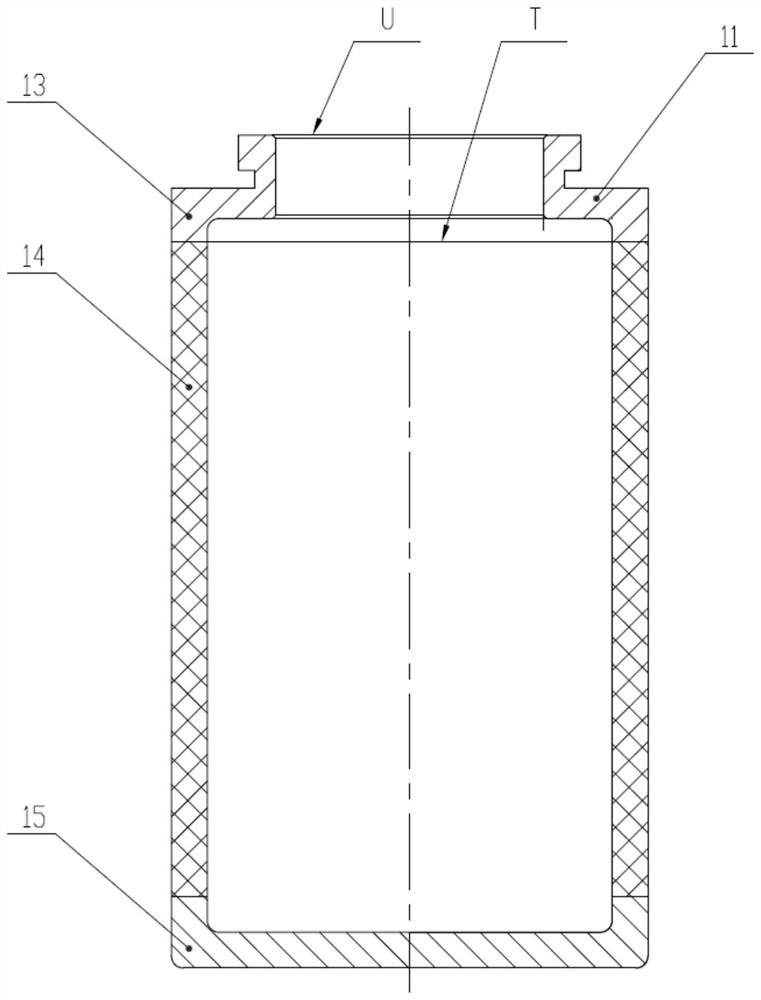

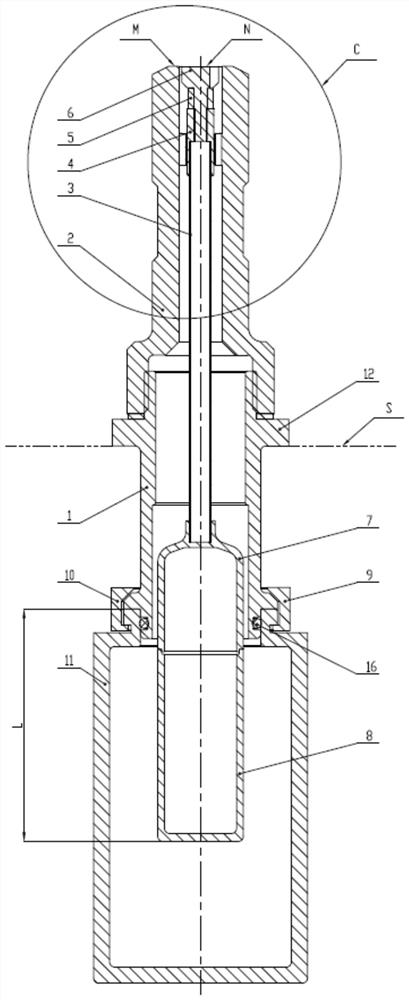

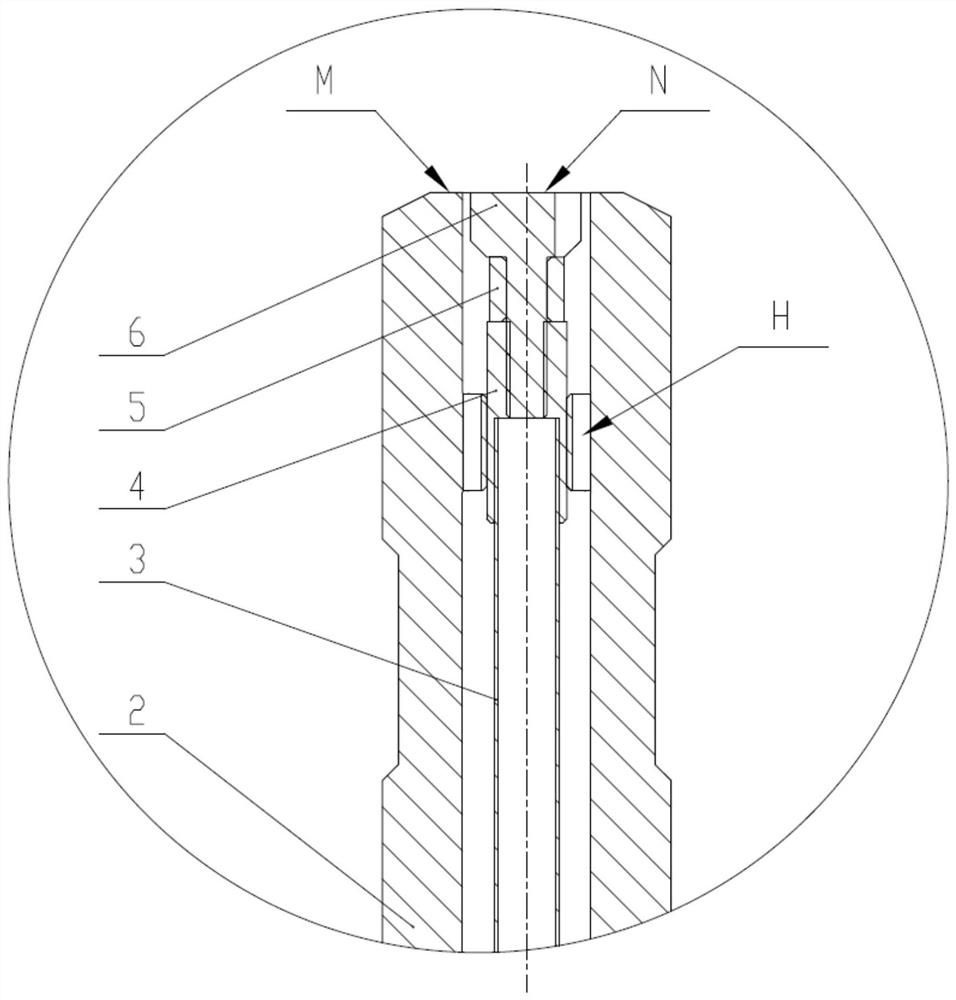

[0029] Example see Figure 1-Figure 4

[0030] This embodiment provides a device for detecting the filtering effect of an engine filter element, which includes a housing, a signal transmission part and a connecting part. There are openings at both ends of the shell, and a cavity in the middle, and the signal transmission part is arranged in the cavity. When using this embodiment to detect, the oil level signal in the filter element to be tested is transmitted to the signal transmission part through buoyancy. The guide piece is clearance fit with the signal transmission piece. The top of the casing is provided with a measurement reference plane M, and the top of the casing is provided with an opening communicating with the cavity, and the top opening is used to discharge the air in the cavity during detection.

[0031] An external liquid level indicator 12 is provided on the outer wall of the housing, and the external liquid level indicator 12 is provided with an external li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com