Device and method for constructing fine stress field by precise principal stress

A technology of principal stress and stress field, applied in the direction of measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as fine analysis, and achieve improved accuracy, simple and refined methods, optimized complexity and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

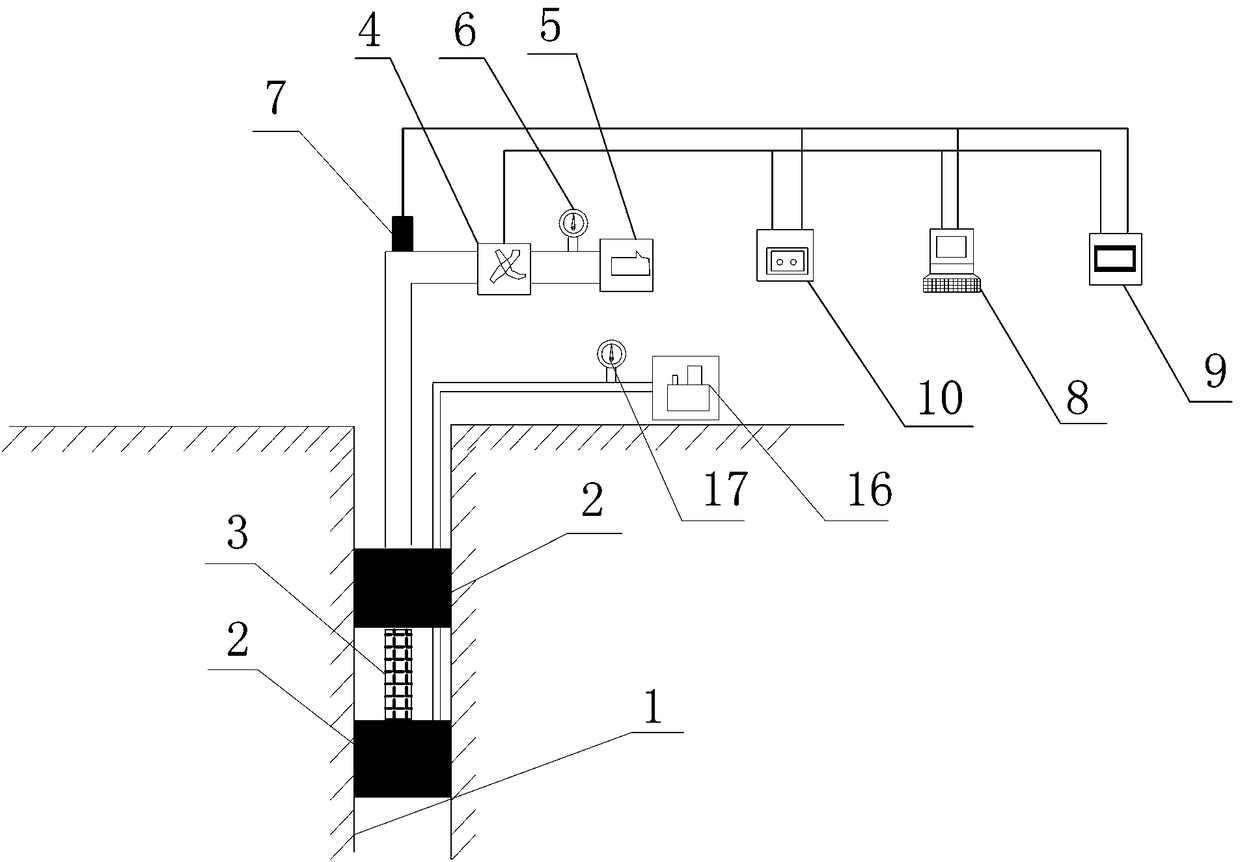

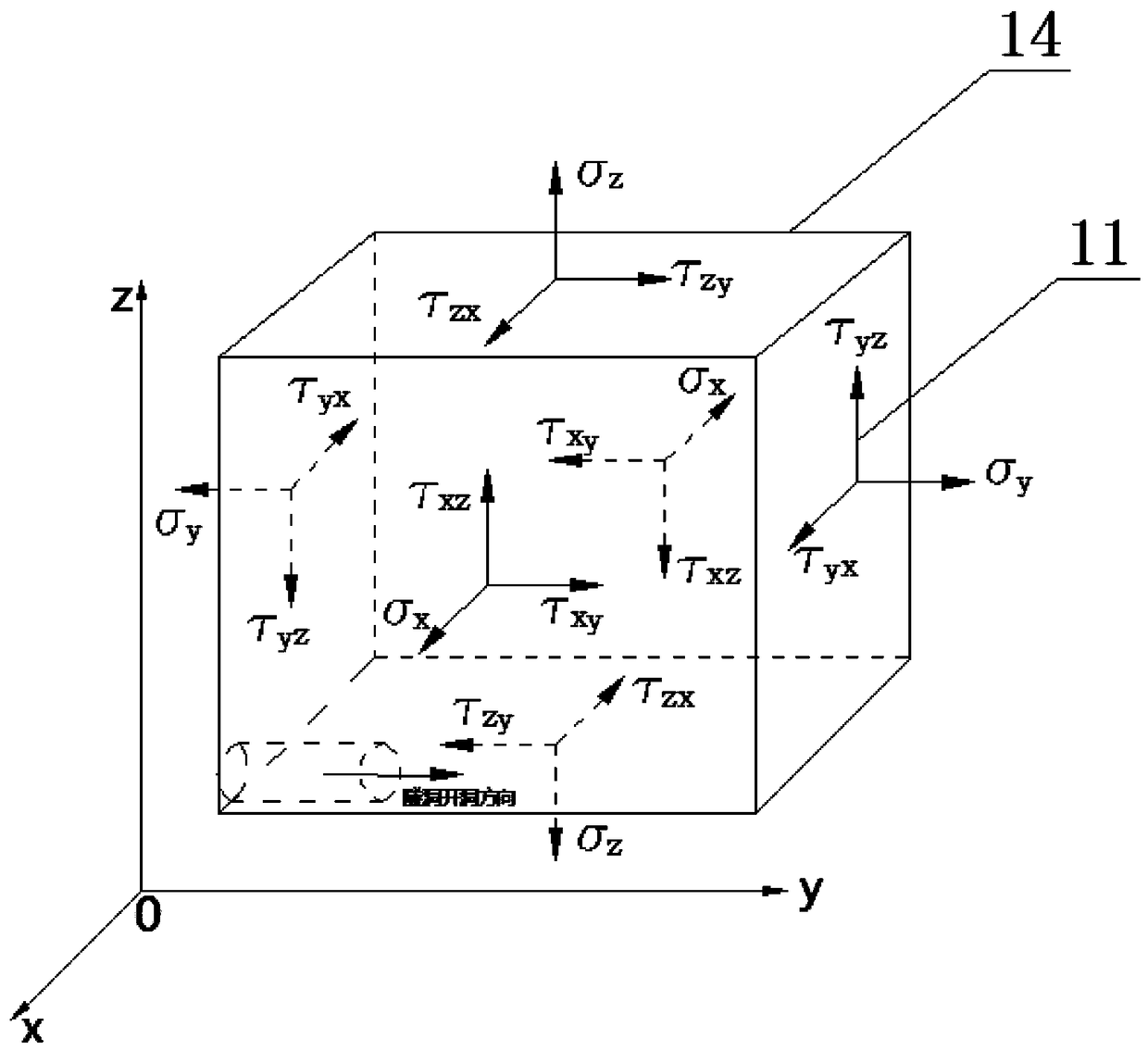

[0047] refer to Figure 1-4 , a device for constructing a fine stress field with precise principal stress, which includes a borehole 1 drilled inside the rock wall to be measured, and two expandable seals arranged at intervals are arranged inside the borehole 1 Blocking blocks 2, a fracturing test section 3 for testing is reserved between the blocking blocks 2, and the fracturing test section 3 is connected to the first high-pressure pump 5 through a pipeline, and a flow meter is installed on the pipeline 4. The first pressure gauge 6 and the pressure sensor 7; the pressure sensor 7 and the flow meter 4 are both connected to the digital acquisition system 8, the digital tape recorder 9 and the X-Y recorder 10 through signal lines at the same time.

[0048] Further, the depth of the borehole 1 is within the testing depth range, and its diameter is smaller than the diameter of the plugging block 2 after expansion.

[0049] Further, the blocking block 2 is connected with a secon...

Embodiment 2

[0051] The method for constructing a fine stress field device using any one of the precise principal stresses comprises the following steps:

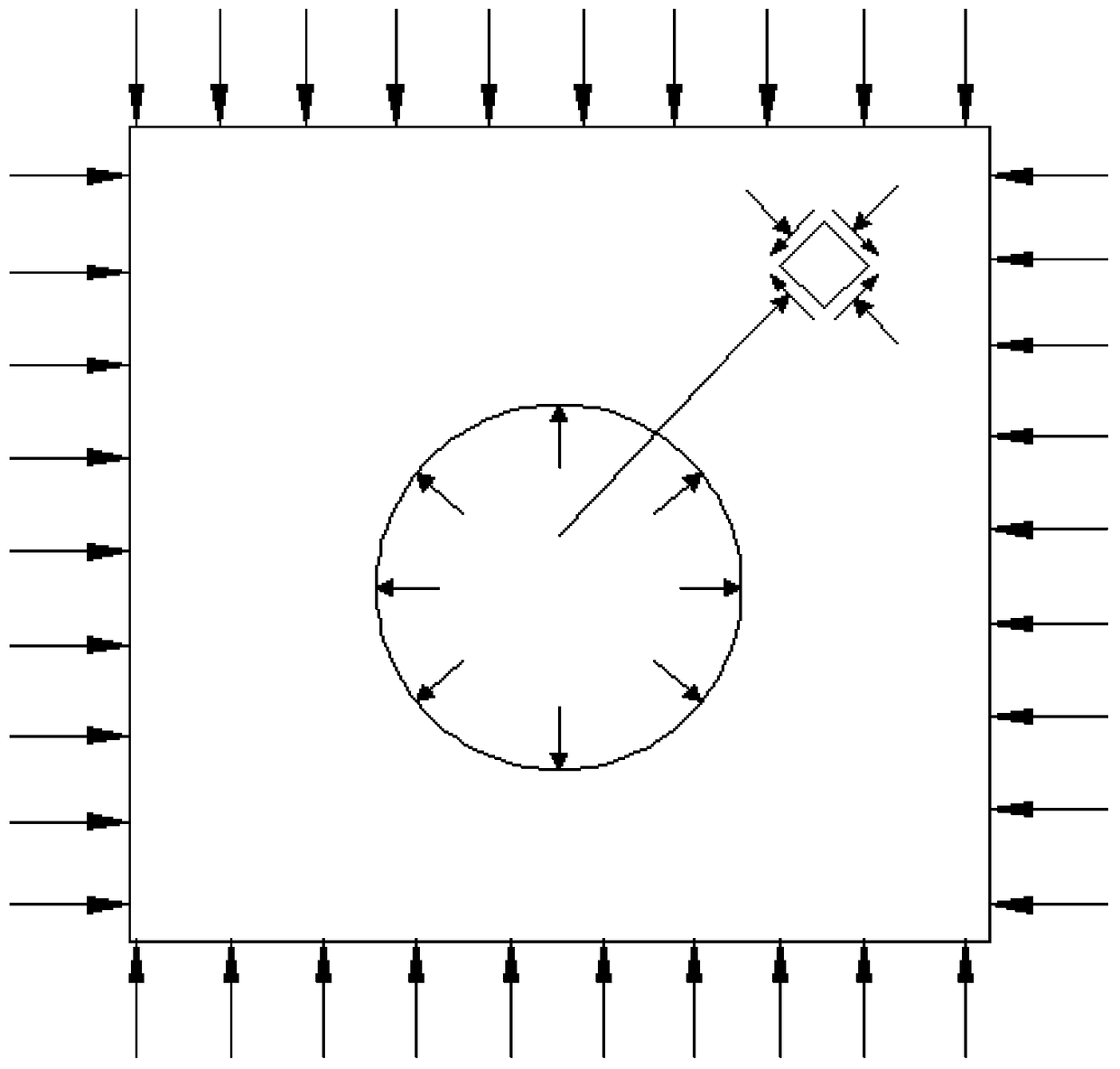

[0052] S1. Measure the stress component of the rock wall by hydraulic fracturing;

[0053] S1.1. Seat seal: Two expandable block blocks 2 are used, placed in the selected test section through the drill pipe, and pressurized so that the block block 2 is seated on the hole wall of the borehole 1 to form The fracturing test section 3 constitutes the pressure-bearing section space, and the hydraulic pressure of the fracturing test section 3 is zero at this time;

[0054] S1.2. Fluid injection and pressurization: push the push-pull switching valve through the drill pipe, and pressurize the fracturing test section 3 with the high-pressure pump 5, so that the hole wall of the borehole 1 is subjected to increasing hydraulic pressure;

[0055] S1.3. Fracturing of the rock wall: under sufficient hydraulic pressure, the hole wall cracks along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com