Magnetic strength detection device and method for magnetic charging motor shell

A technology of strength detection and magneto, which is applied in the direction of magnetic performance measurement, the size/direction of the magnetic field, etc., can solve the problems of large error of detection results, large deviation of measurement values, and the inability to guarantee the stability of the detection probe and the motor casing, etc., to achieve The effect of reducing the detection error and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

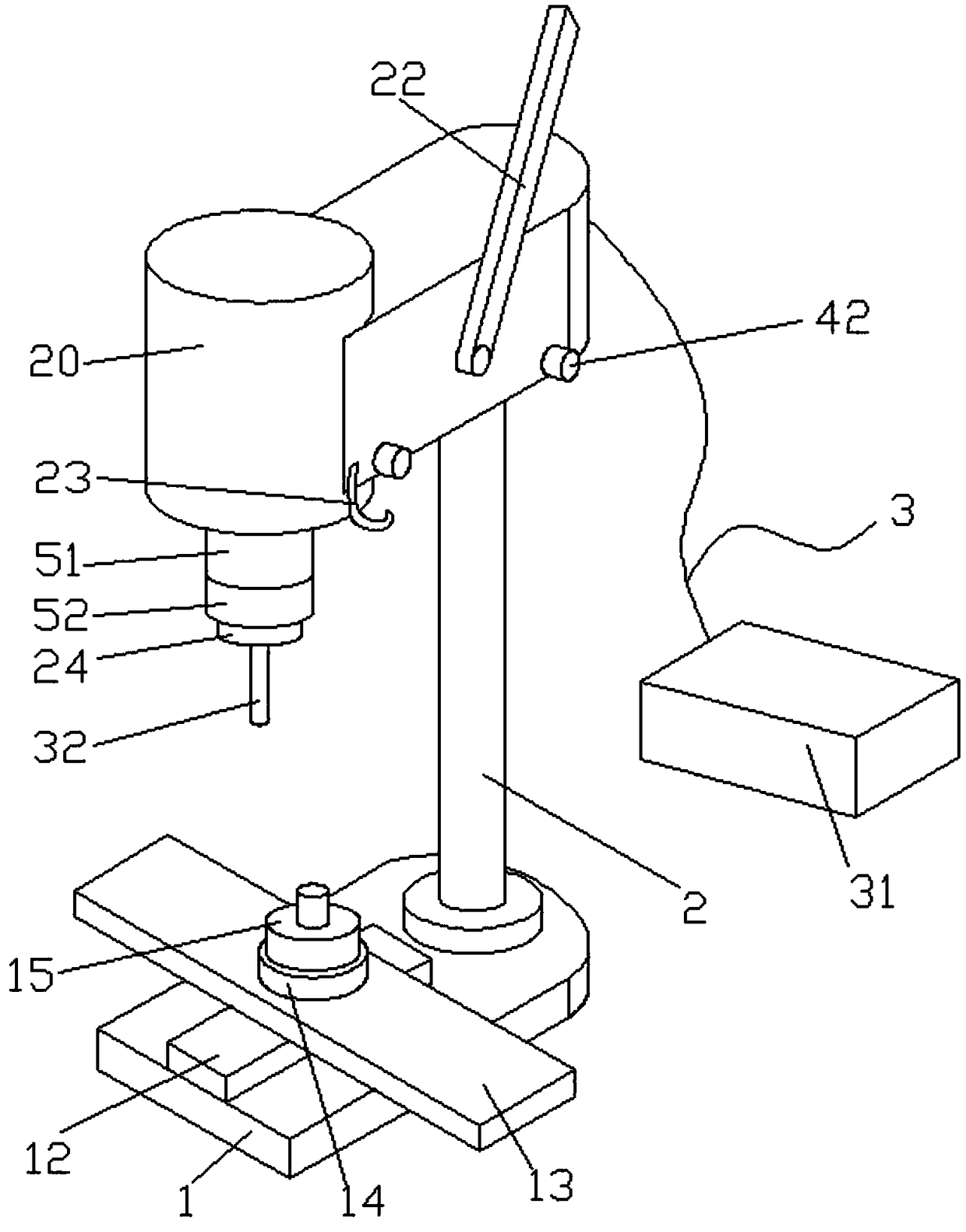

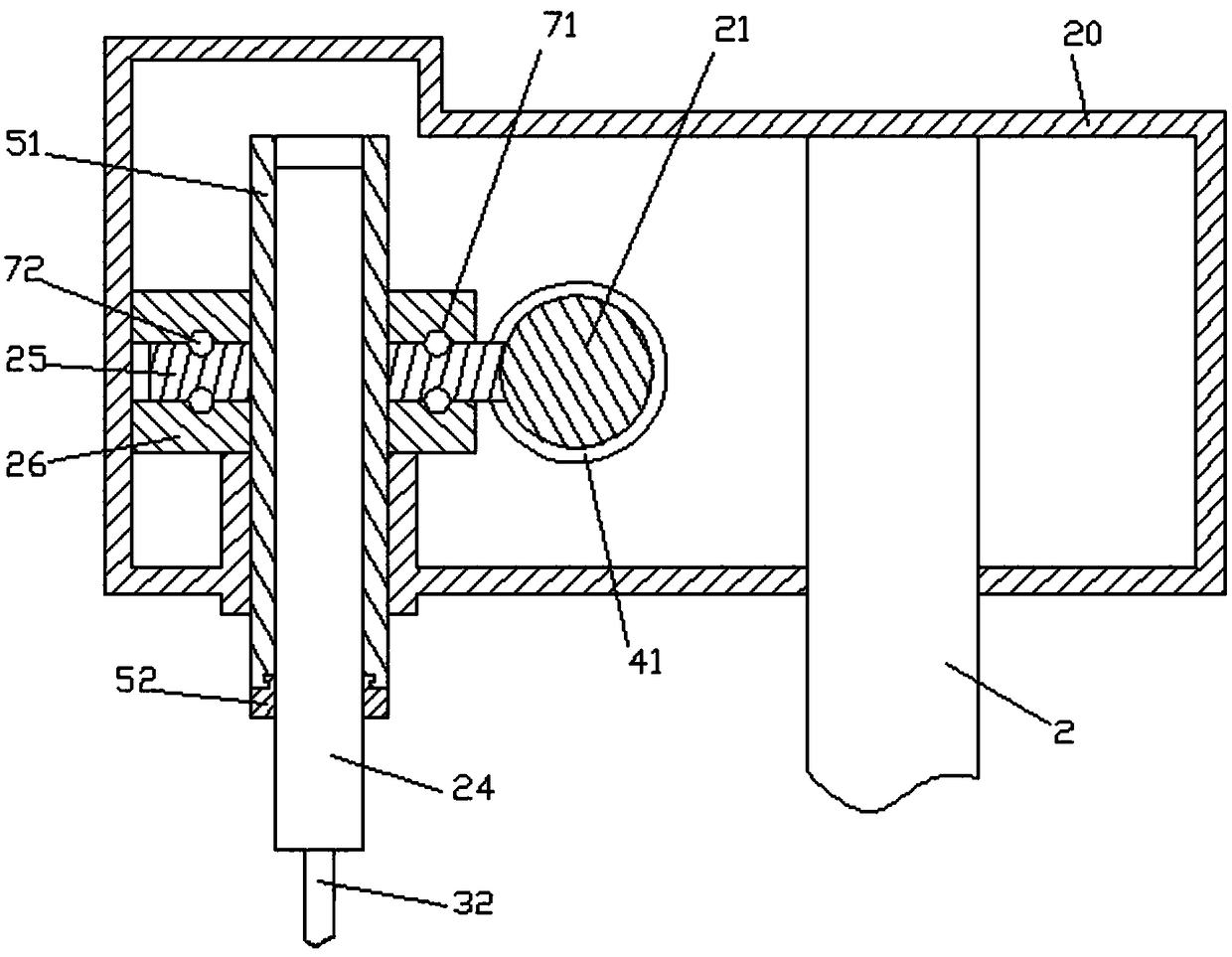

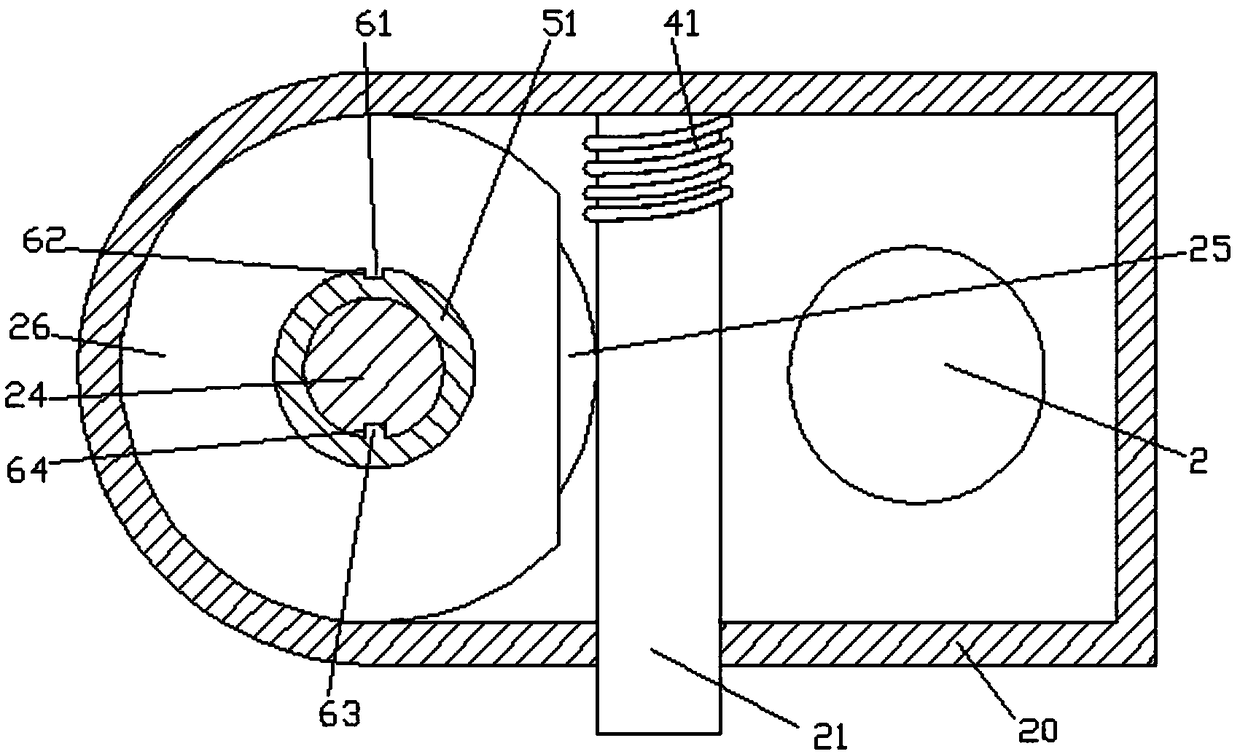

[0025] combine figure 1 , figure 2 Shown; a magnetized motor housing magnetic strength detection device, including a base 1, a column 2, a gauss meter 3, the column 2 is vertically installed on the top of the base 1, the base 1 is equipped with a longitudinal feed rocker 12, and the longitudinal feed The upper part of the rocker 12 is equipped with a transverse feed rocker 13, the upper part of the transverse feed rocker 13 is fixedly installed with a turntable 14, the upper part of the turntable 14 is equipped with a chuck 15, the upper end of the column 2 is installed with a headstock 20, and a worm is installed inside the headstock 20 21. One end of the worm 21 is connected to the lower pressure rod 22. The lower pressure rod 22 is located outside the headstock 20. The side of the headstock 20 where the lower pressure rod 22 is installed is provided with a positioning hook 23. The end side of the headstock 20 is equipped with a main shaft 24. The main shaft 24 Perpendicul...

Embodiment 2

[0035] combine figure 1 , figure 2Shown; a magnetized motor housing magnetic strength detection device, including a base 1, a column 2, a gauss meter 3, the column 2 is vertically installed on the top of the base 1, the base 1 is equipped with a longitudinal feed rocker 12, and the longitudinal feed The upper part of the rocker 12 is equipped with a transverse feed rocker 13, the upper part of the transverse feed rocker 13 is fixedly installed with a turntable 14, the upper part of the turntable 14 is equipped with a chuck 15, the upper end of the column 2 is installed with a headstock 20, and a worm is installed inside the headstock 20 21. One end of the worm 21 is connected to the lower pressure rod 22. The lower pressure rod 22 is located outside the headstock 20. The side of the headstock 20 where the lower pressure rod 22 is installed is provided with a positioning hook 23. The end side of the headstock 20 is equipped with a main shaft 24. The main shaft 24 Perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com