Singular perturbation model-based method for cooperatively controlling shape and thickness of hot rolled sheet

A singular perturbation and cooperative control technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problem of low precision of plate thickness control, achieve strong real-time performance, small steady-state error, and fast response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation process of the present invention for the coordinated control of the shape and thickness of the hot-rolled thin plate is as follows:

[0040] Step 1: Discrete singular perturbation modeling and shape and thickness collaborative controller design for the hot-rolled sheet rolling process

[0041] The four-roll bending hot rolling mill is selected as the controlled object, and the discrete singular perturbation model is established as in formula (1), and the control law (3) is designed, and the controller gain is obtained through theorem 1. The parameters of the controlled system are shown in Table 1.

[0042] Table 1 Parameter list of the controlled system

[0043]

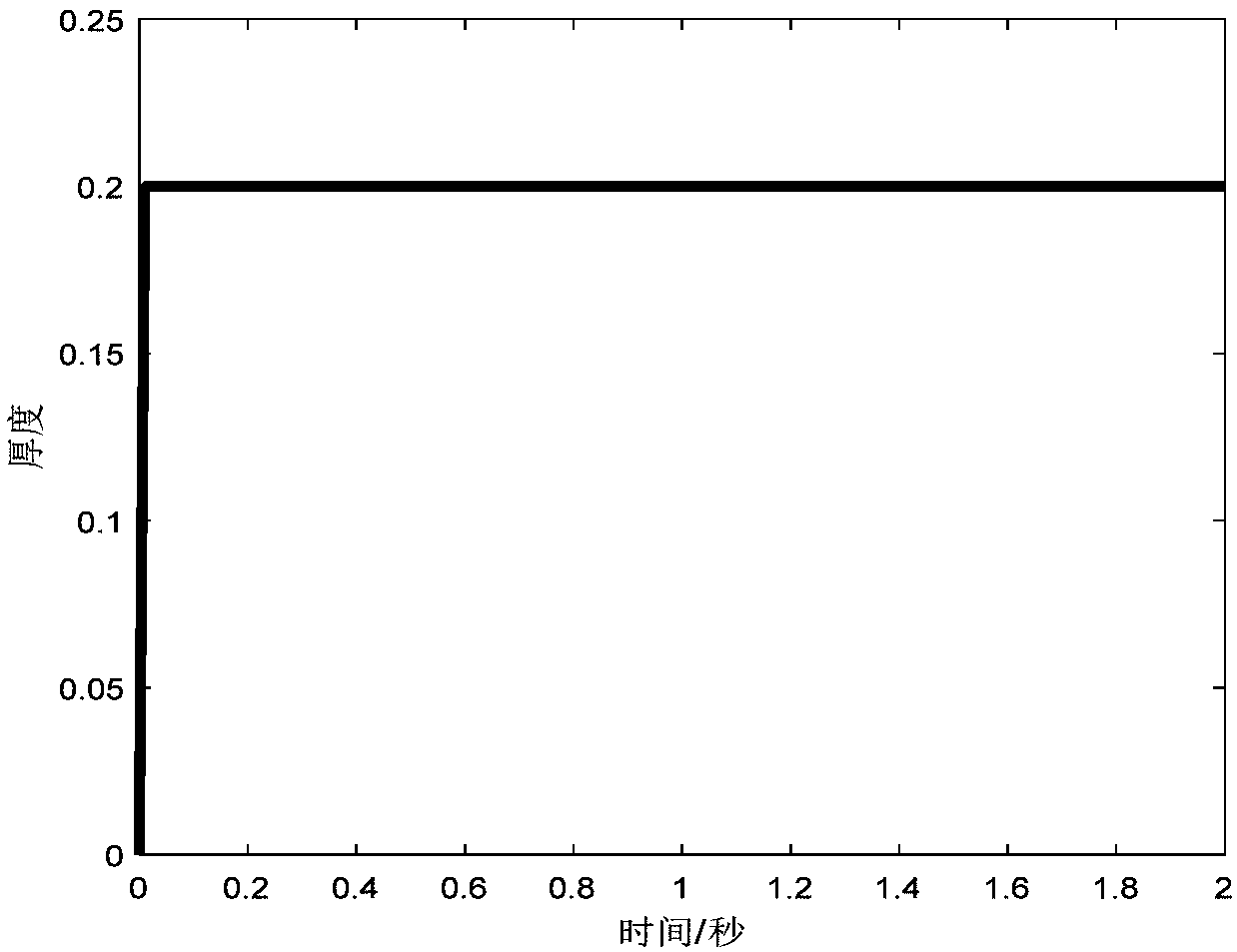

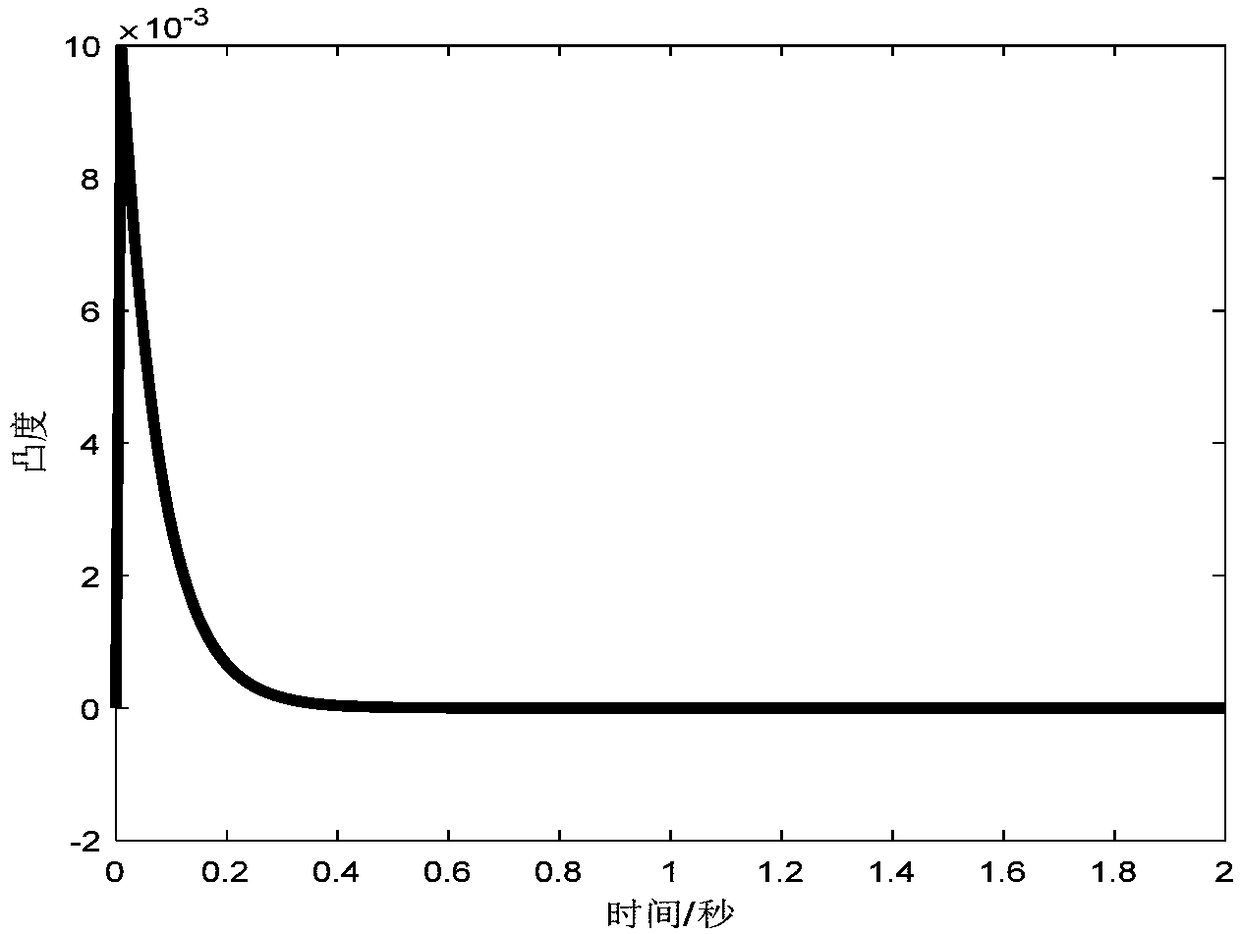

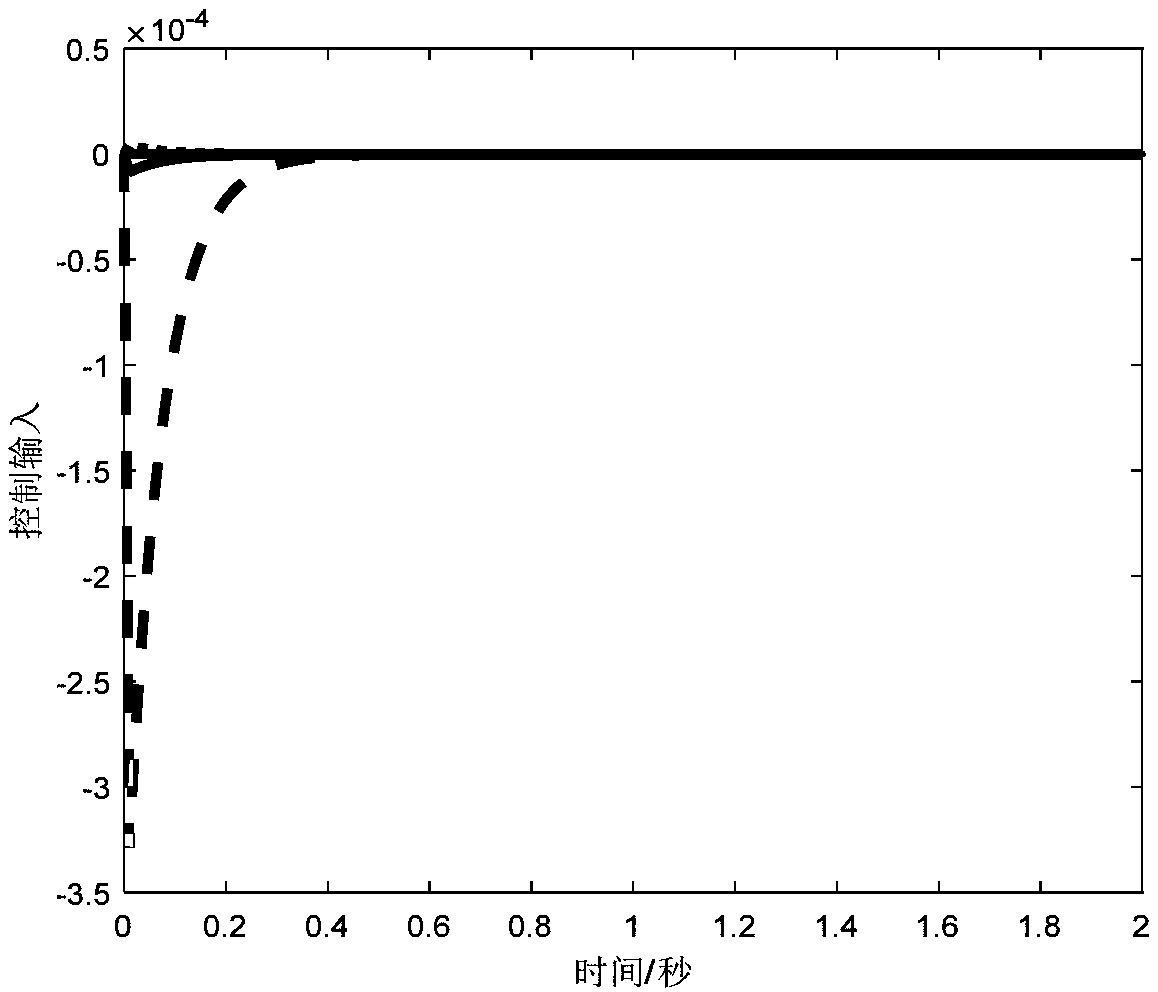

[0044] Let the initial value x(0)=[0.2 0.01 01×8]T, ε=0.1, carry out the simulation, the response curve of the closed-loop system is as follows figure 1 and 2 and control input responses such as image 3 .Simulation results show that the control method can achieve cooperative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com