A Robust Preset Performance Control Method for Distributed Manipulator System

A technology of preset performance and control methods, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as complex weight parameter adjustment and online use of complex and unfavorable control laws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

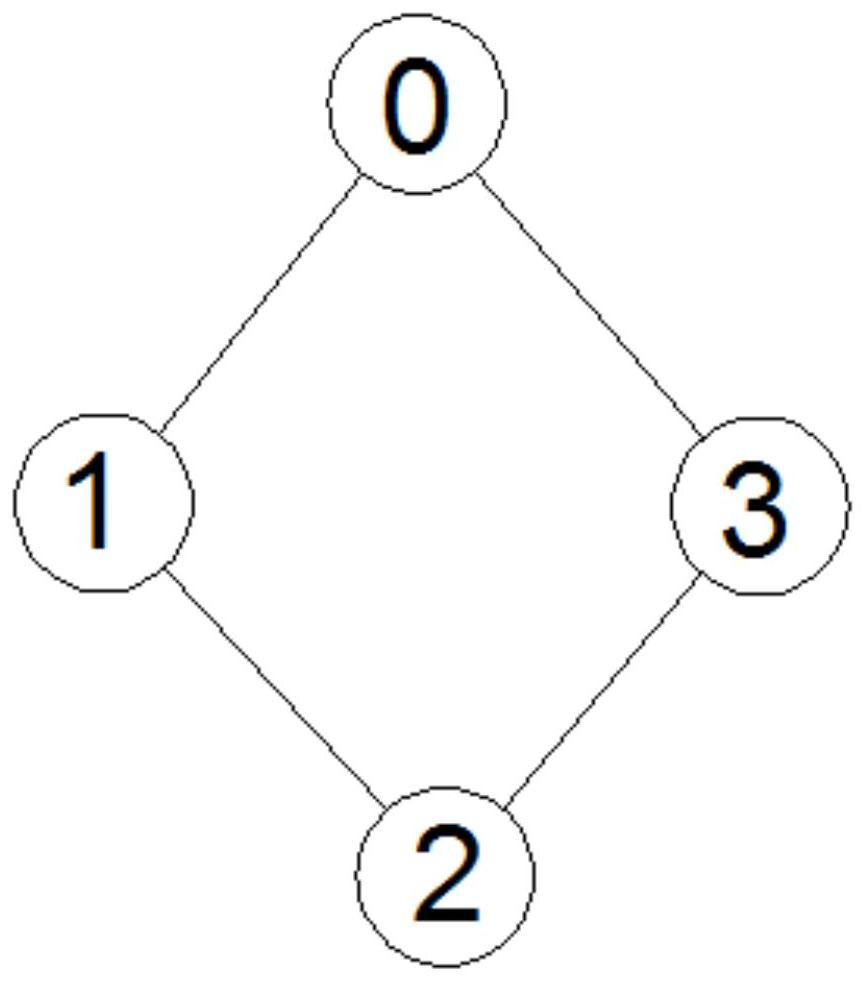

[0080] The present invention selects multiple second-order manipulator systems, a typical nonlinear mechanical system, as a research object, and performs master-slave stability control of multiple manipulator systems. Suppose there are 3 slave manipulator systems, one master manipulator system, and the information topology between master and slave manipulator systems is as follows: figure 1 shown.

[0081] In the distributed stability control study, the parameters of the slave manipulator are set as:

[0082] Slave arm system 1: m 1,1 =0.5kg, m 1,2 = 1.5kg, l 1,1 = 1.0m, l 1,2 =0.8m;

[0083] Slave arm system 2: m 2,1 = 1.0kg, m 2,2 = 2.0kg, l 2,1 = 1.5m, l 2,2 = 1.0m;

[0084] From robotic arm system 3: m 3,1 = 1.5kg, m 3,2 = 1.0kg, l 3,1 = 1.2m, l 3,2 = 1.0m;

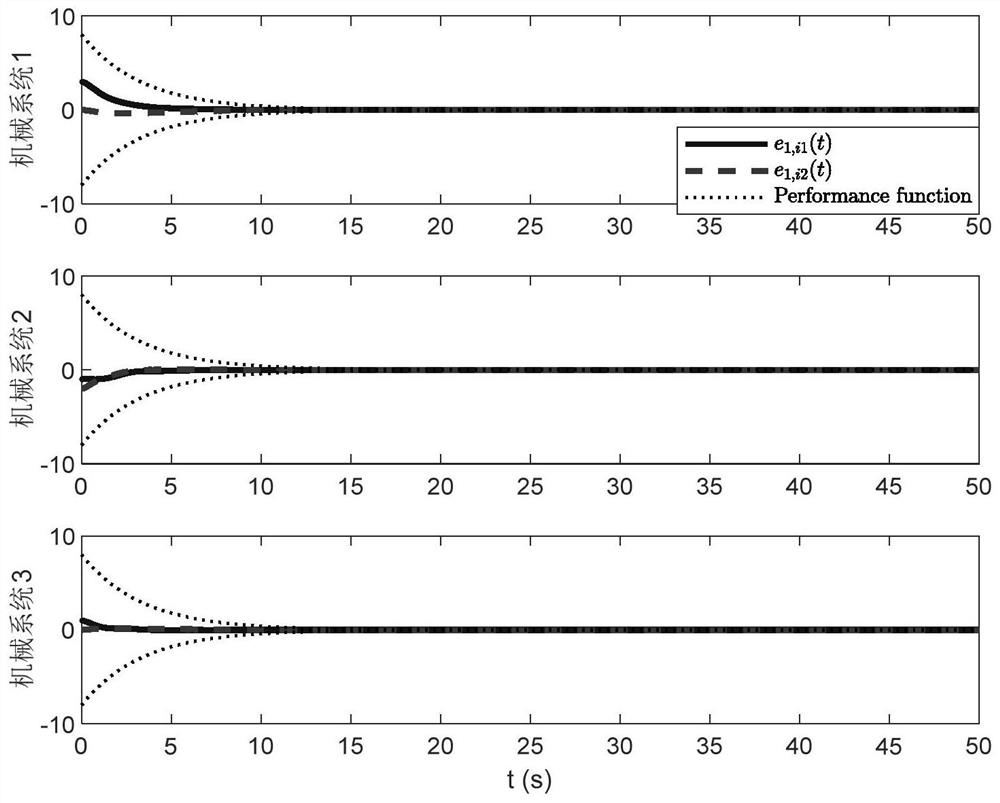

[0085] The performance function parameters of the three slave manipulator systems are all set as:

[0086] ρ i,0 =8,ρ i,∞ =0.01,l i =0.3,κ i,r =1(i=1,2,3);

[0087] The controller parameters of th...

Embodiment 2

[0092] Multiple second-order manipulator systems, a typical nonlinear mechanical system, are selected as the research object to carry out tracking control of multiple manipulator systems. The parameters and initial state of the control system are the same as those in the first embodiment.

[0093] Suppose the desired trajectory of the main manipulator system is:

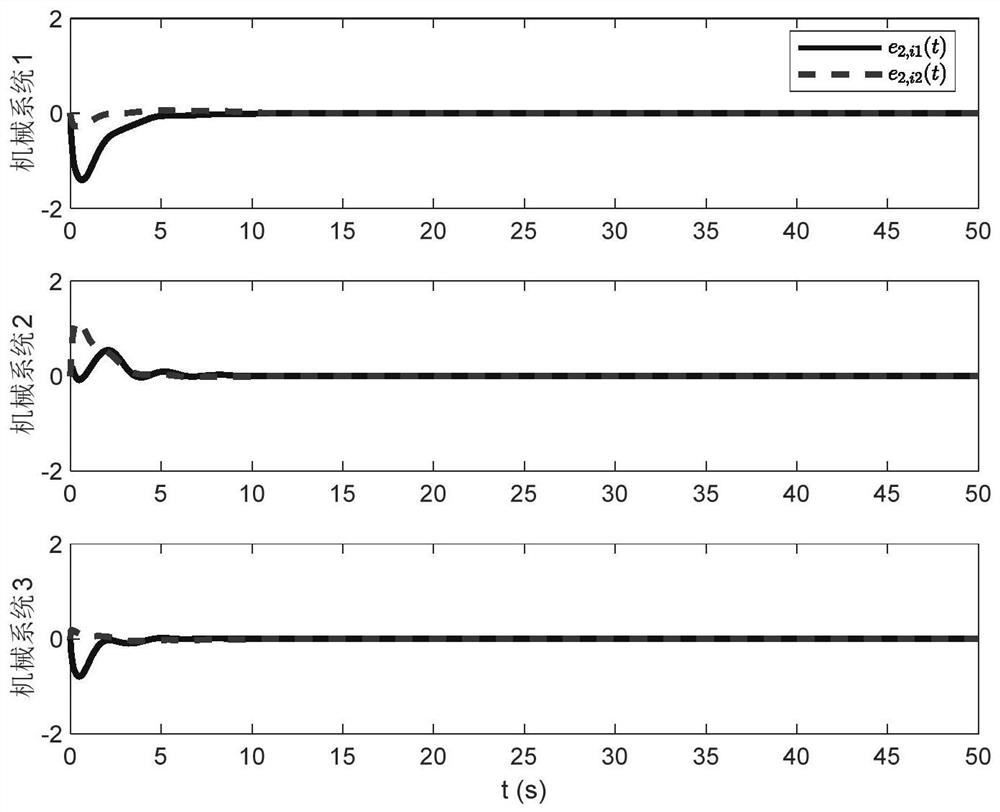

[0094] The corresponding simulation results are as Figures 6 to 9 As shown in the figure, it can be concluded that 1) under the unknown dynamic model and external disturbance, the slave manipulator system can track the desired joint angle command in about 25s, and the preset joint angle tracking error performance envelope can Realized in the whole time domain, compared with the stable control in the first embodiment, the response time of the distributed tracking follows the target instruction and there is a delay phenomenon; 2) the input from the manipulator system is bounded, so in the present invention A distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com