Control method of intelligent concrete shotcrete robot for tunnel

A control method, concrete technology, used in tunnels, tunnel linings, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

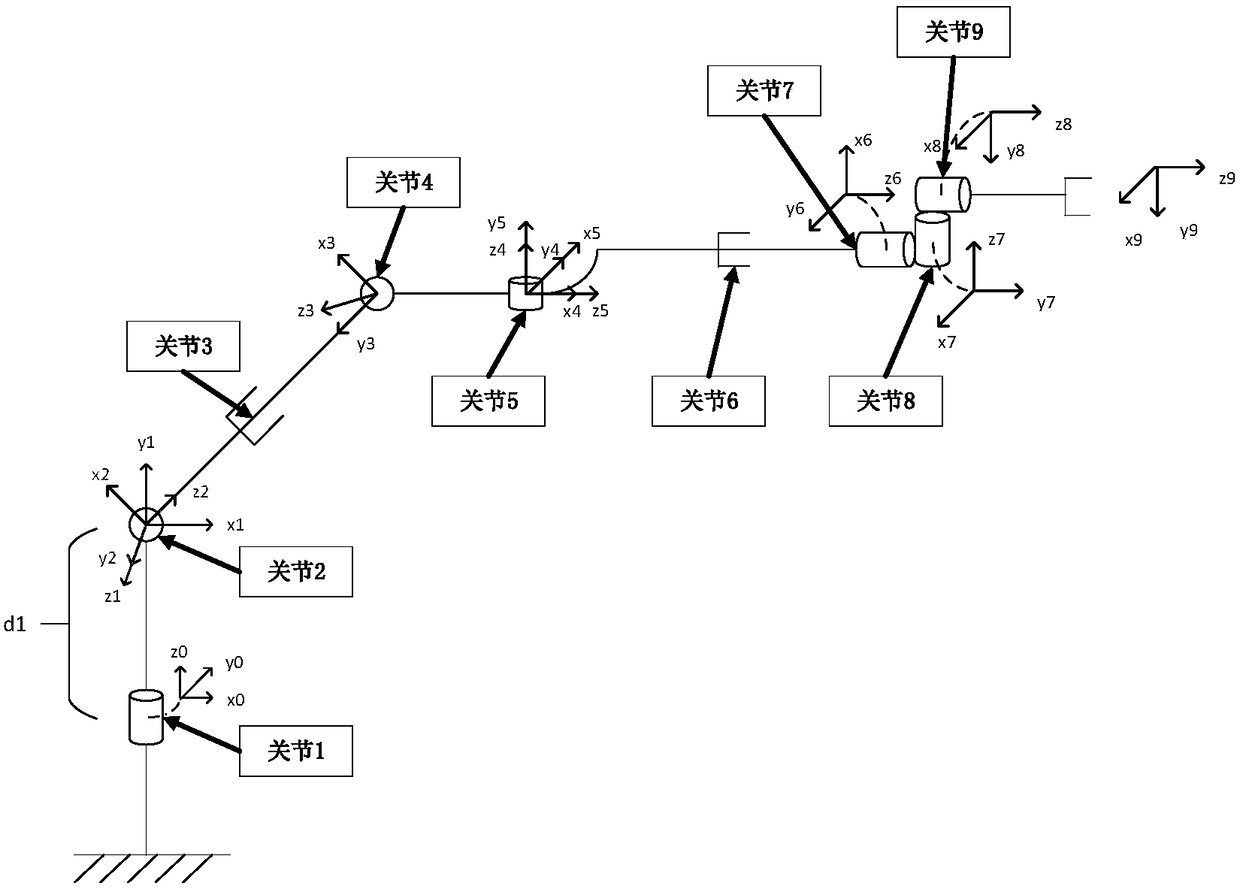

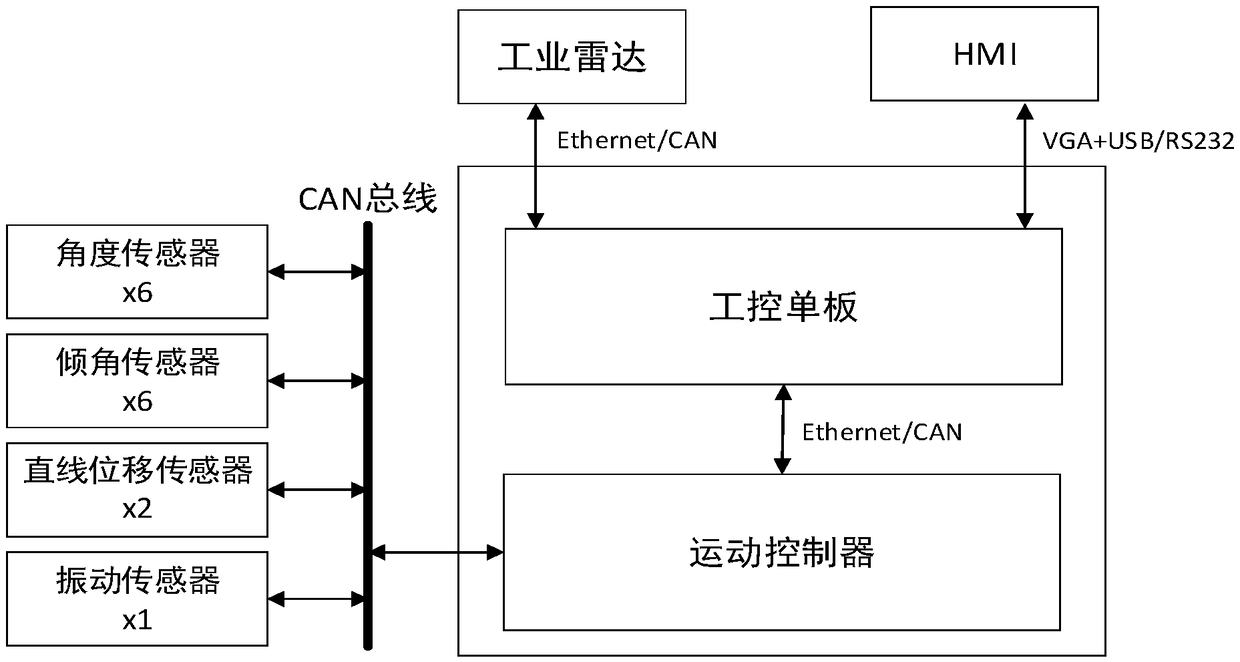

[0017] Step 1: hardware system construction; the present invention takes the KC30 series spraying machine equipment of Changsha Keda Intelligent Equipment Co., Ltd. as an example (but the related technology of the present invention is applicable to other similar equipment), and the mechanical arms of this equipment are nine in total The joints are driven by hydraulic pressure; the core of the control system is the motion controller and the industrial control board, and sensors are installed on each joint of the arm frame. The hardware block diagram is as follows: figure 2 shown;

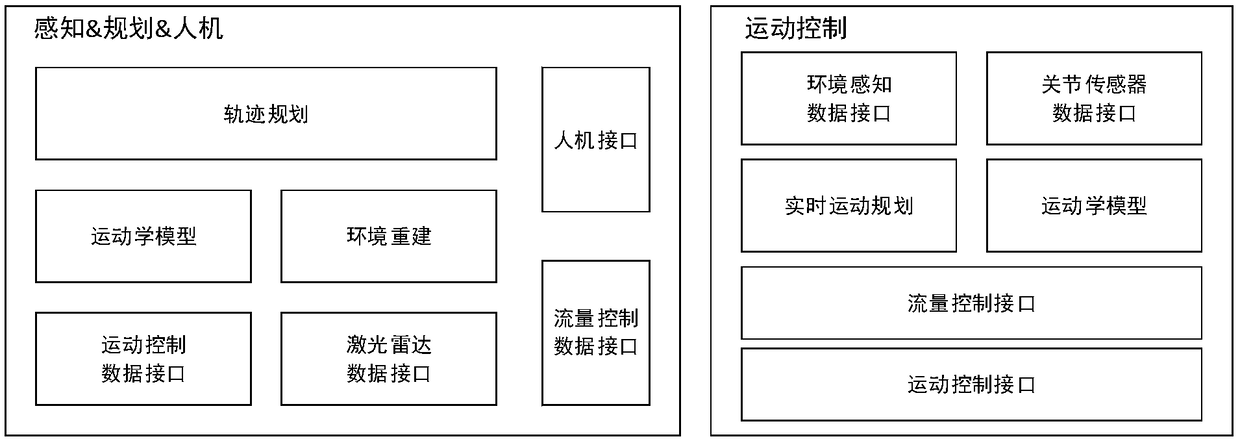

[0018] The hardware architecture is mainly aimed at the two core tasks of real-time motion control and rapid environment perception. The former controls the manipulator to complete specified actions in real time through the sensor data of each joint and the planning results, and the latter receives data from environmental perception sensors (mainly lidar) to quickly complete the environment. Perceiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com