Non-singular terminal sliding mode force position control method for constraint-oriented reconfigurable manipulator

A non-singular terminal and control method technology, applied in the field of robot control method and constrained system control, can solve the problems of chattering, slow convergence speed, low tracking accuracy, etc., to suppress chattering effect, increase system reliability and improve system reliability. The effect of stability and lower application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

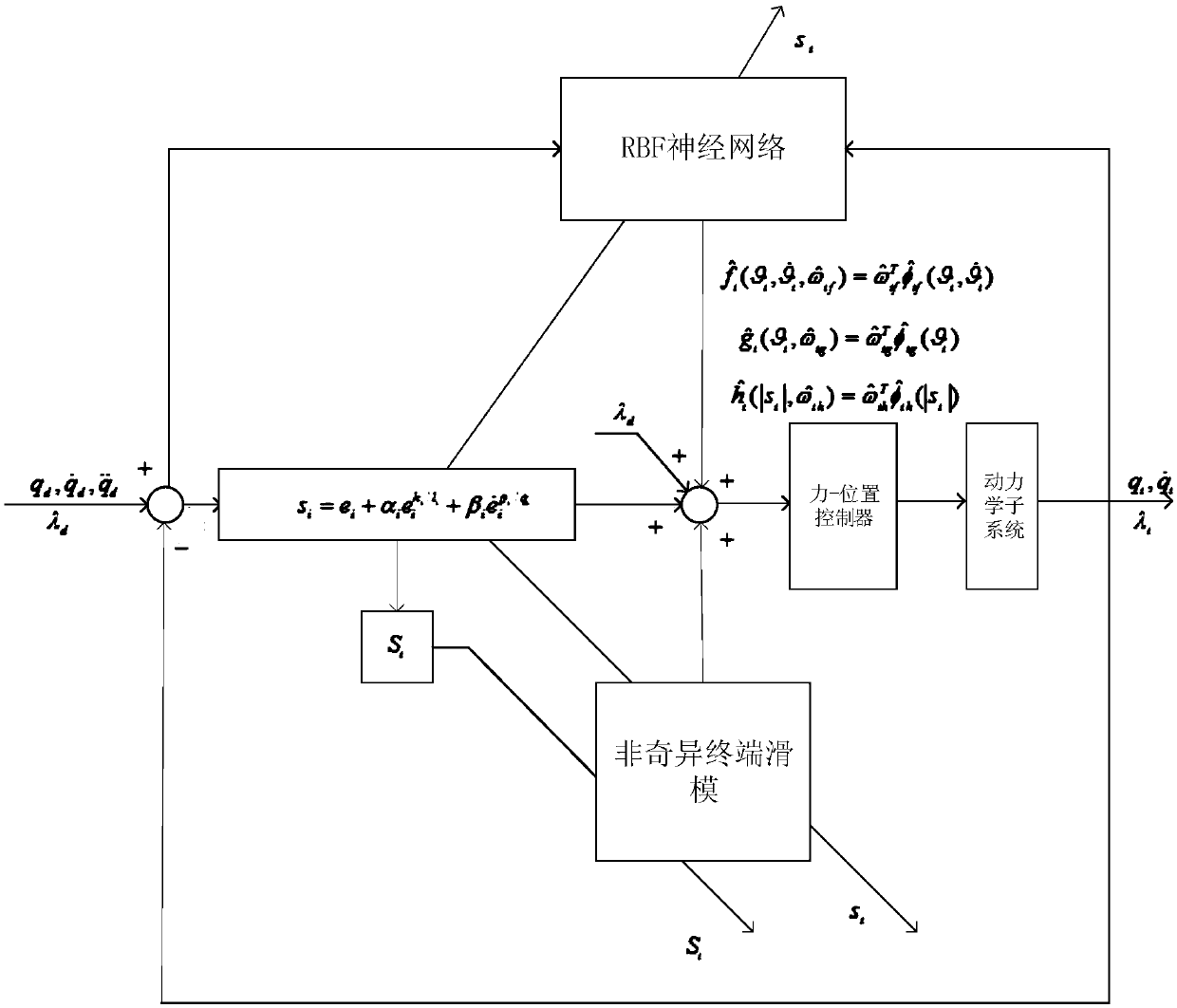

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

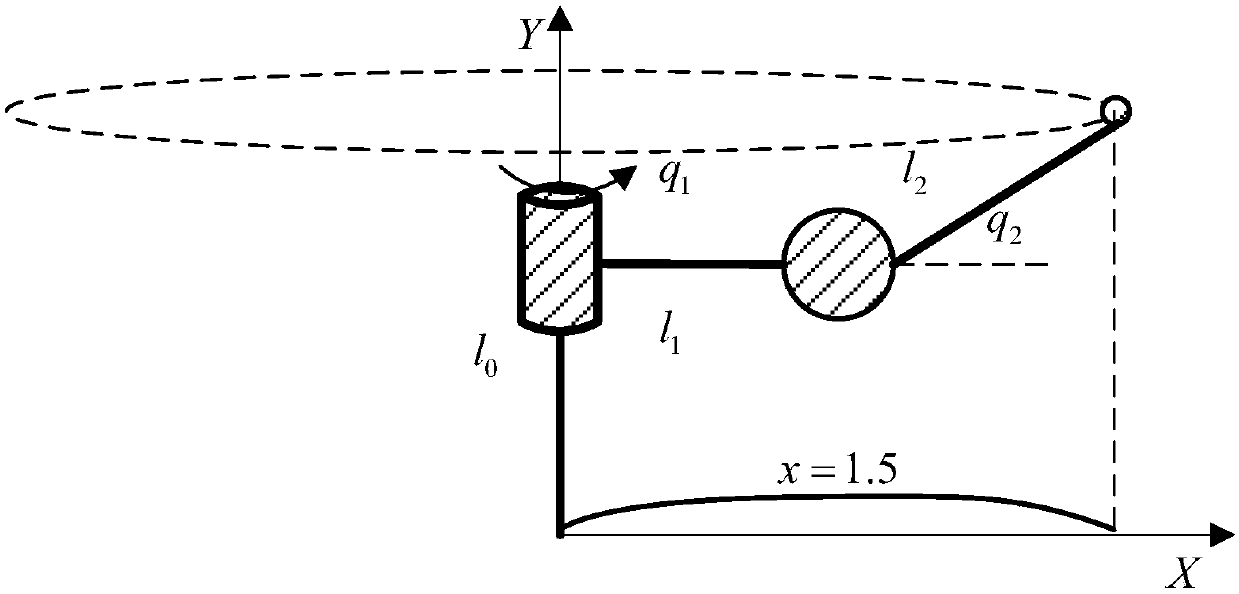

[0045] The constraint-oriented non-singular terminal sliding mode force position control method of the reconfigurable manipulator described in the present invention is generally suitable for integrating standard modules and interfaces, and can recombine and configure its own configuration according to different task requirements. Construct the robotic arm system. Since the control method designed in the present invention is applicable to various manipulator configurations, two configurations A and B are selected as examples to illustrate the effectiveness of the method designed in the invention.

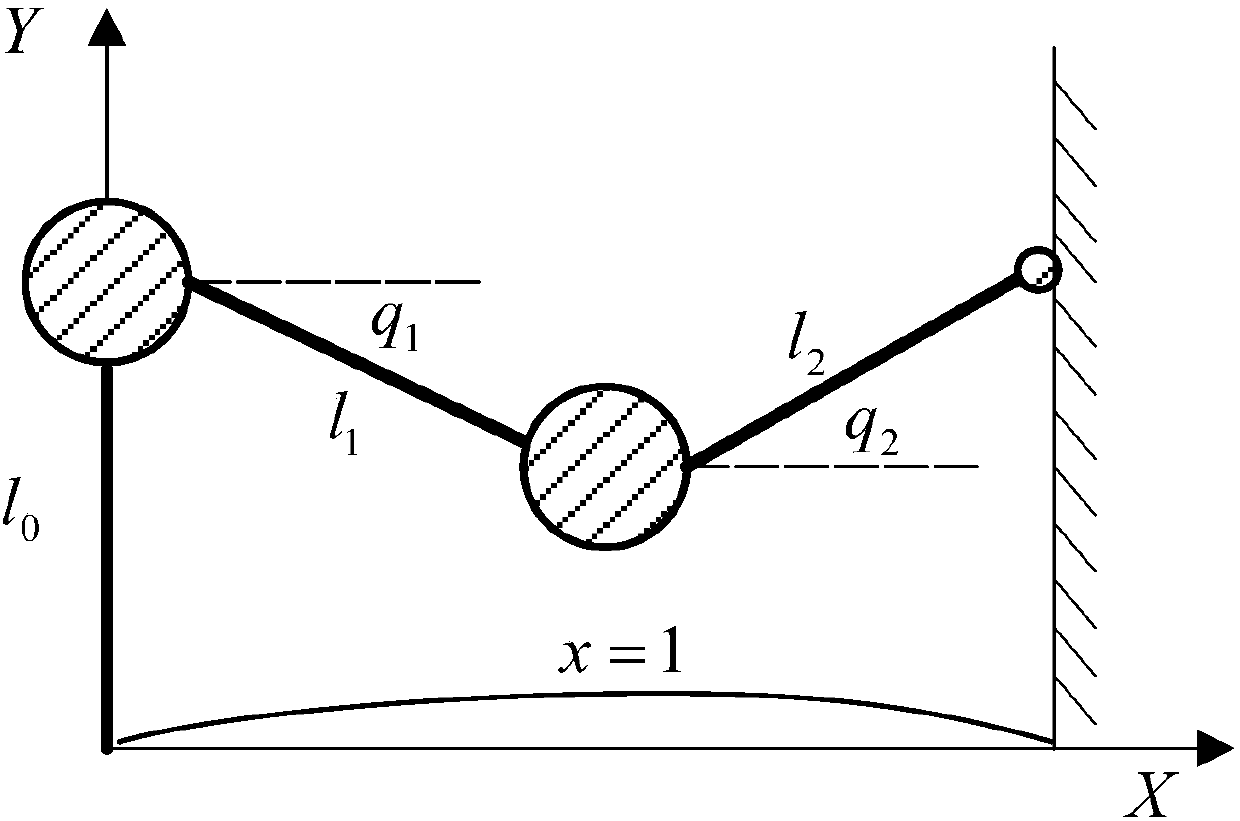

[0046] Such as figure 1 As shown, the configuration A of the application object of the non-singular terminal sliding mode force position control method for the constraint-oriented reconfigurable manipulator of the present invention, for the convenience of descripti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com