Wheel hub direct drive air suspension system and cooperative control method based on nmpc

An air suspension, direct drive technology, applied in suspension, elastic suspension, vehicle components, etc., can solve the problems of dynamic characteristic lag, increased constraints, serious parameter coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

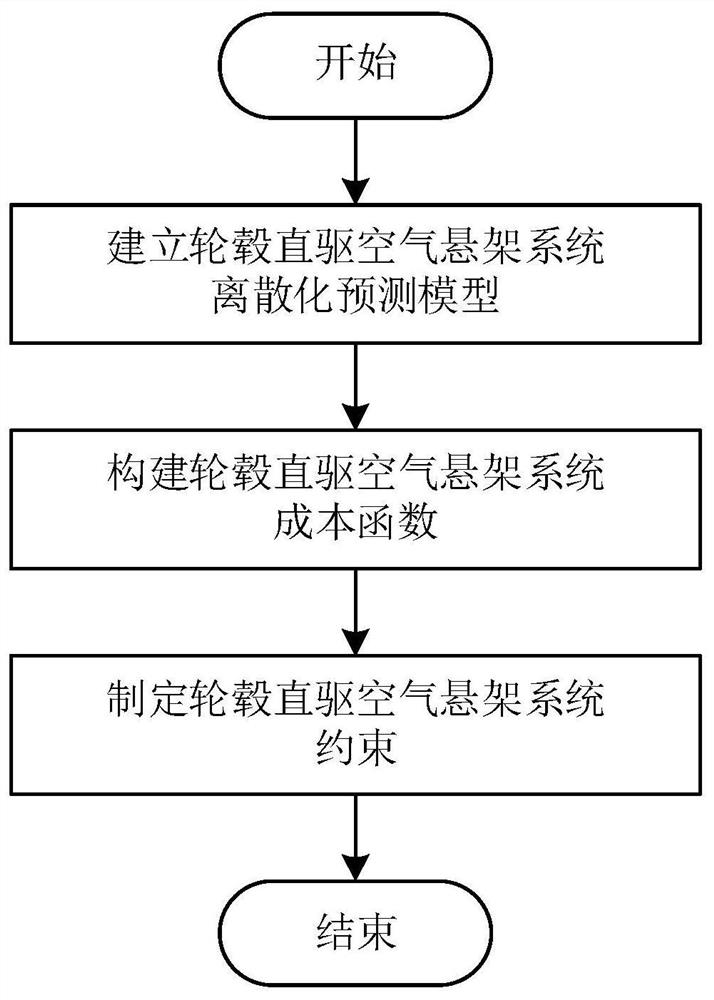

Method used

Image

Examples

Embodiment Construction

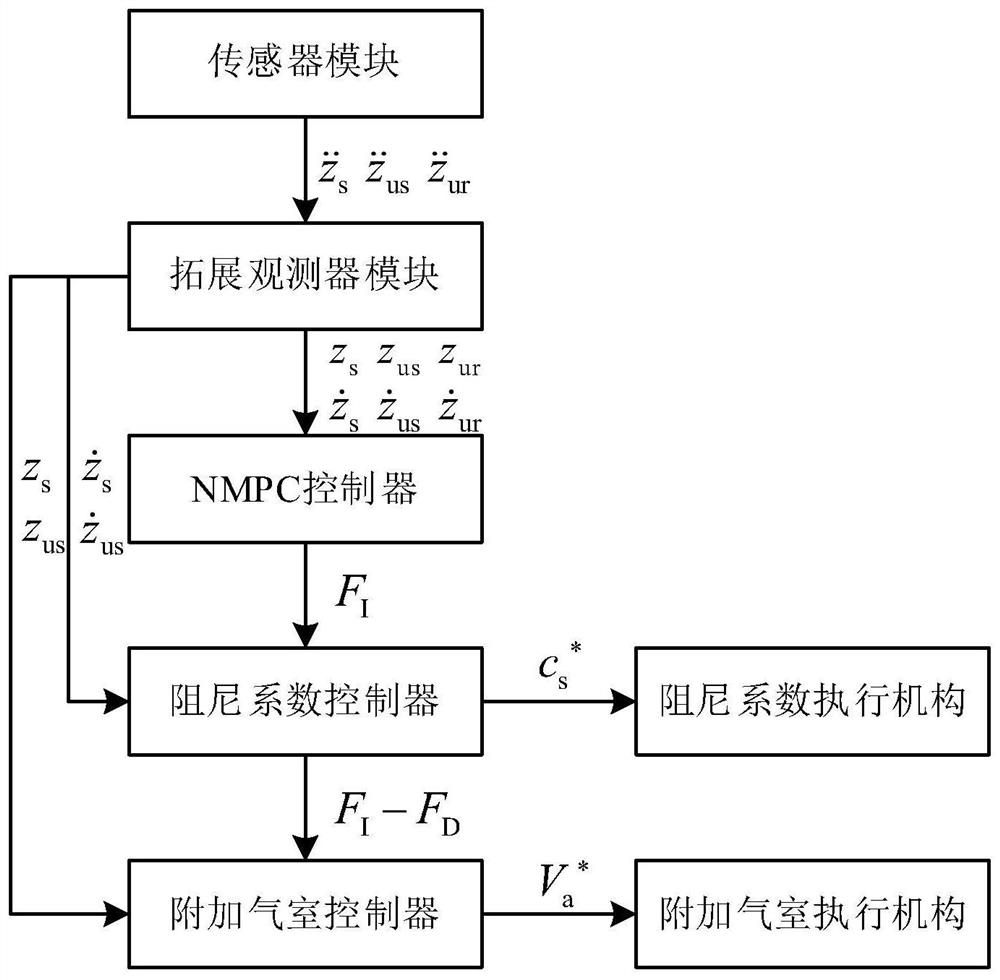

[0018] see figure 1 , the NMPC-based wheel hub direct drive air suspension system of the present invention is composed of a sensor module, an extended observer module, an NMPC controller, a damping coefficient controller, a damping coefficient actuator, an additional air chamber controller and an additional air chamber actuator. Consists of 7 parts. The sensor module, the extended observer module, the NMPC controller, the damping coefficient controller and the additional air chamber controller are connected in series in sequence. The output end of the coefficient controller is connected to the input end of the damping coefficient actuator, and the output end of the additional air chamber controller is connected to the input end of the additional air chamber actuator.

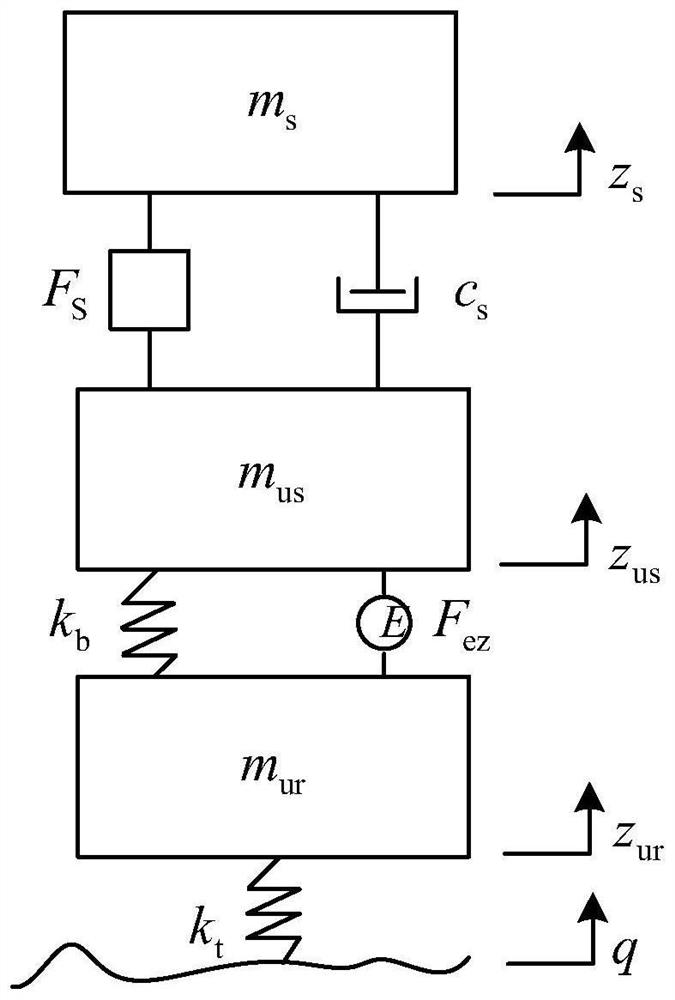

[0019] The sensor module consists of three acceleration sensors, which are respectively installed at the sprung mass, the tire and the motor rotor mass, and the motor stator and the remaining unsprung mass, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com