A vacuum pump lifecycle management method

A technology of full life cycle and management method, applied in the field of product life cycle management, can solve problems such as difficulty in unified management of product data and order information, inability to grasp product dynamic information, untimely response to customers, etc., to improve maintenance service quality, Effective storage of corporate knowledge and the effect of reducing the amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below with reference to the accompanying drawings and embodiments.

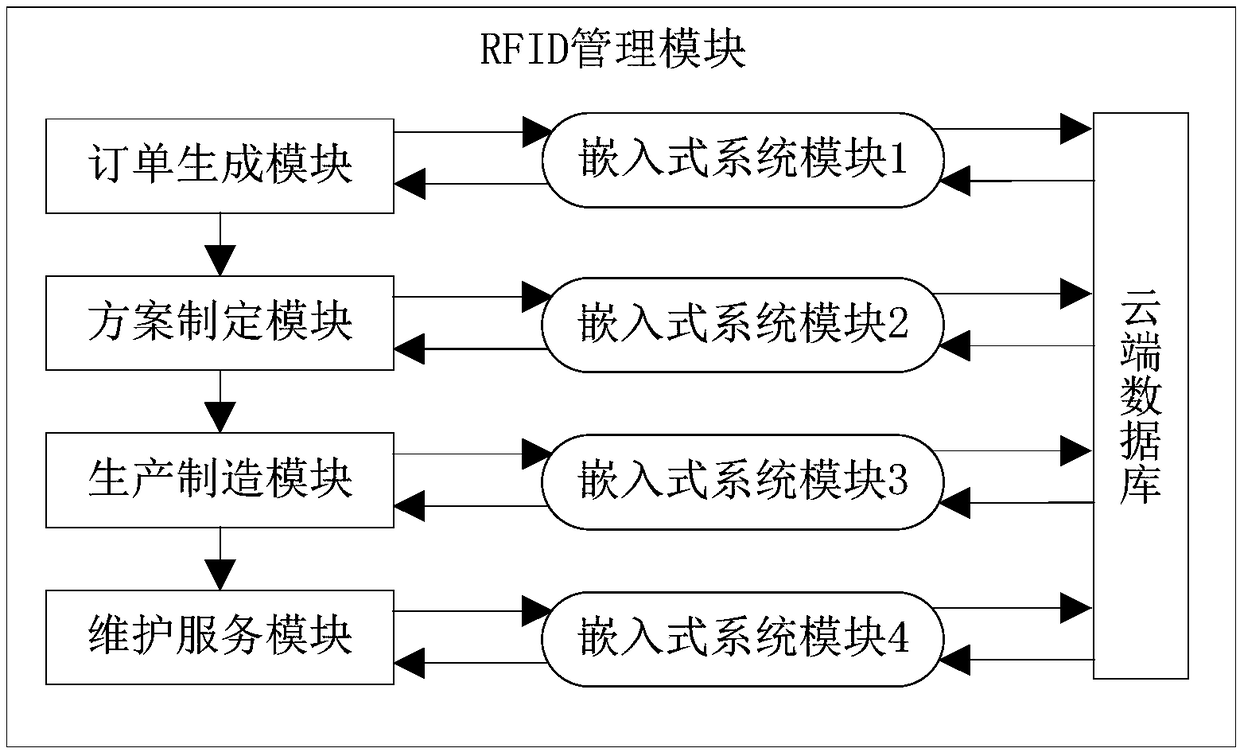

[0045] like figure 1 , shows the intelligent management system for the whole life cycle of the vacuum pump. This embodiment is an intelligent management system for the whole life cycle of a vacuum pump, including: a cloud database, an order generation module, a scheme formulation module, a manufacturing module, a maintenance service module, an RFID management module, and an embedded system module.

[0046] Specifically, the cloud database is connected with the order generation module, the plan formulation module, the manufacturing module, and the maintenance service module through the embedded system module, and is used to store the information of each stage in the whole life cycle of the vacuum pump product.

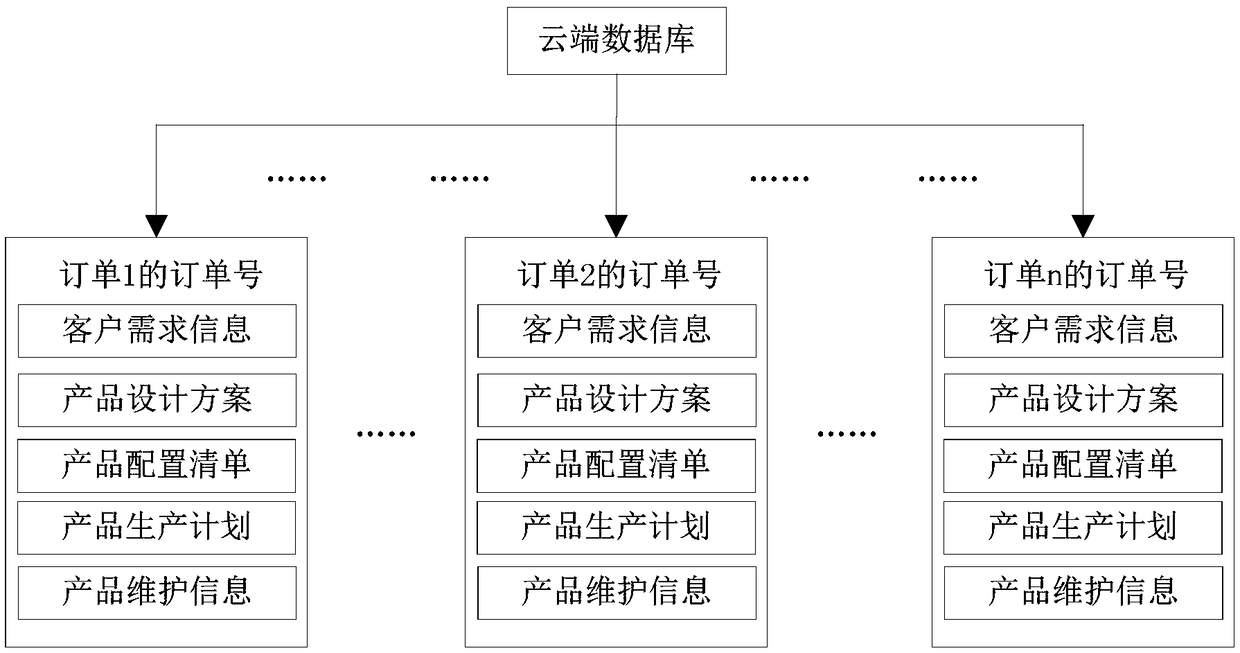

[0047] like figure 2 , which shows that the storage method of the cloud database is that the whole life cycle information of the vacuum pump pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com