A compact mounter screw type large-scale feeding system

A feeding system and placement machine technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problem of inability to realize PCB feeding, slow down the feeding speed of placement machines, and reduce the speed of placement machines. Feeding efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

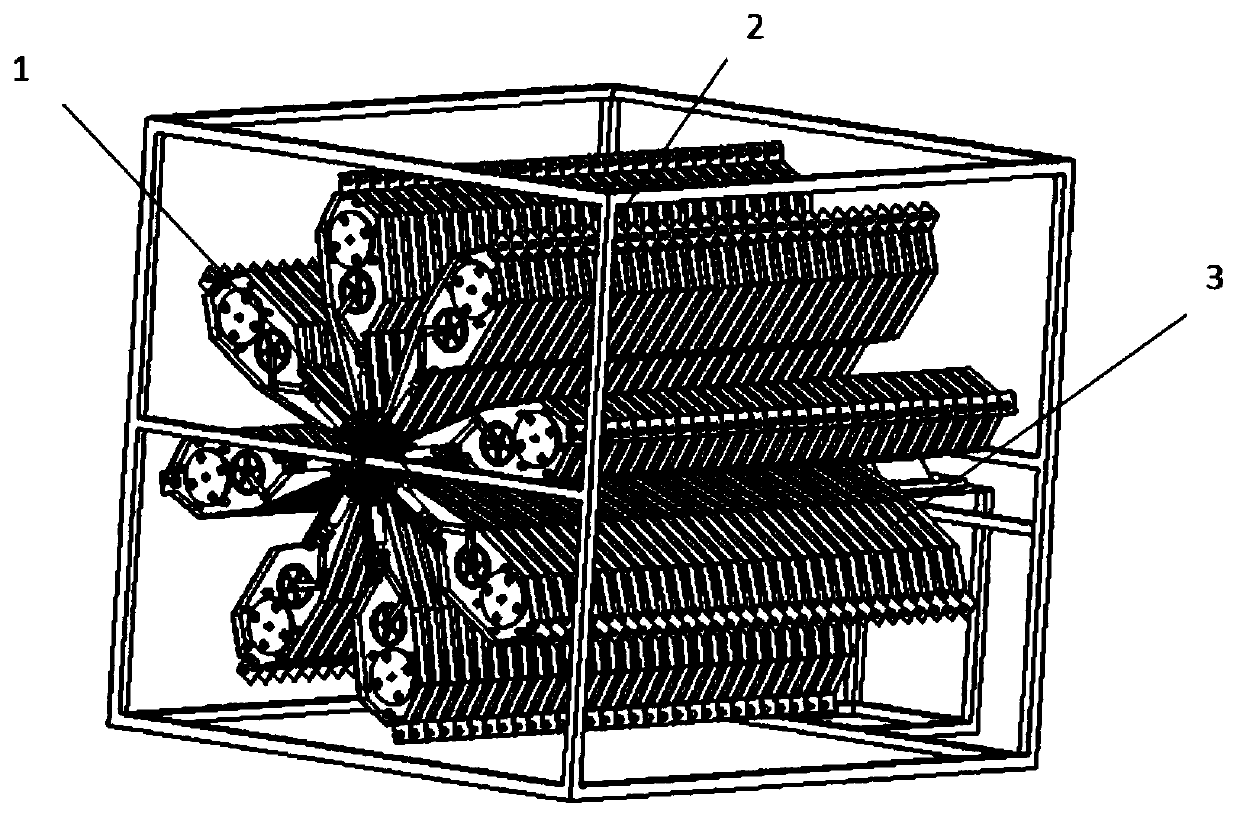

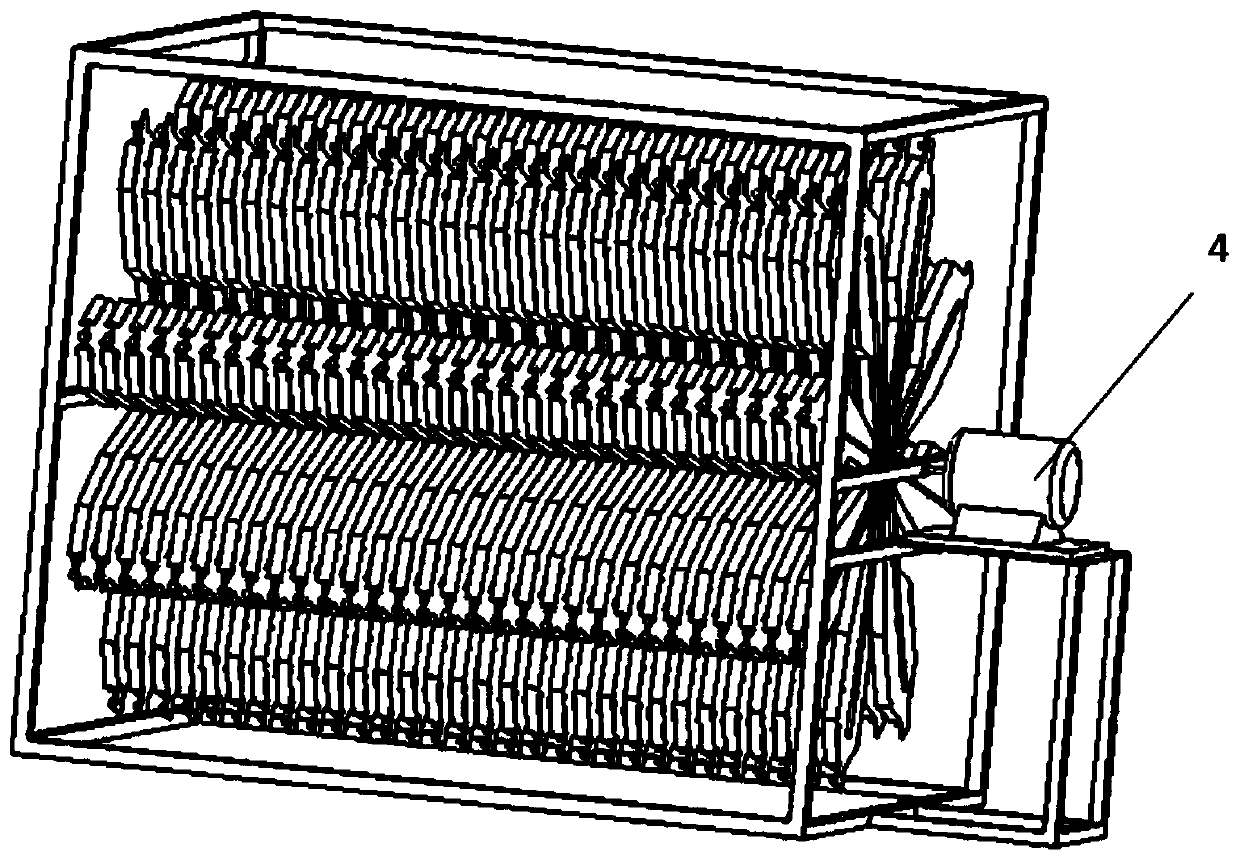

[0036] The invention discloses a screw type large-scale feeding system for a compact placement machine; the system includes an integral outer frame 2 and a feeder 3, the integral outer frame 2 is fixedly provided with a first driving device, and the feeder 3 is fixedly arranged inside There is a second drive and a third drive.

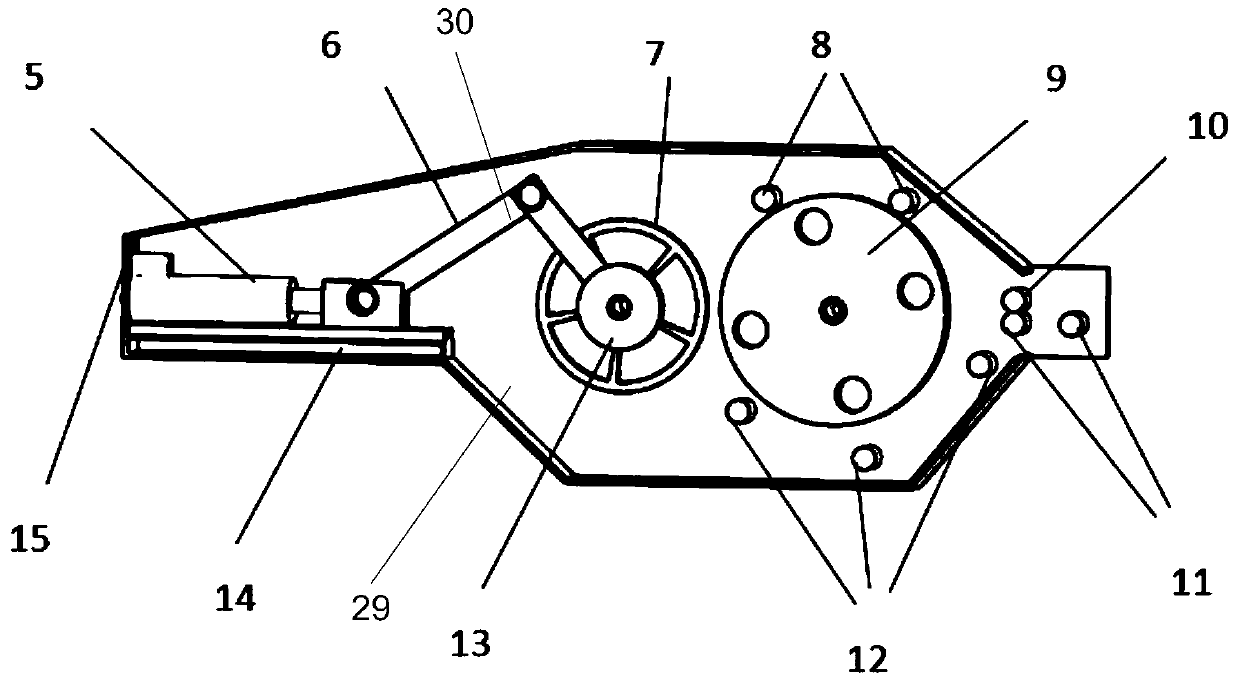

[0037] The overall outer frame 2 is a square frame structure composed of several supporting frames, and the first driving device is fixed in the overall outer frame 2; the first driving device includes a driving motor 4, a bearing and a turret 1, and the turret 1 includes a rotating shaft 16 and radial connecting rod 28; the axis of the rotating shaft 16 coincides with the vertical centerline of the overall outer frame 2 in space The interference fit enables the rotating shaft 16 to rotate relative to the overall outer frame 2; a drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com