Button cell cleaning system

A cleaning system and button battery technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as high work intensity and unstable cleaning effect, and achieve reduced production intensity and automation. High degree of anti-reflux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

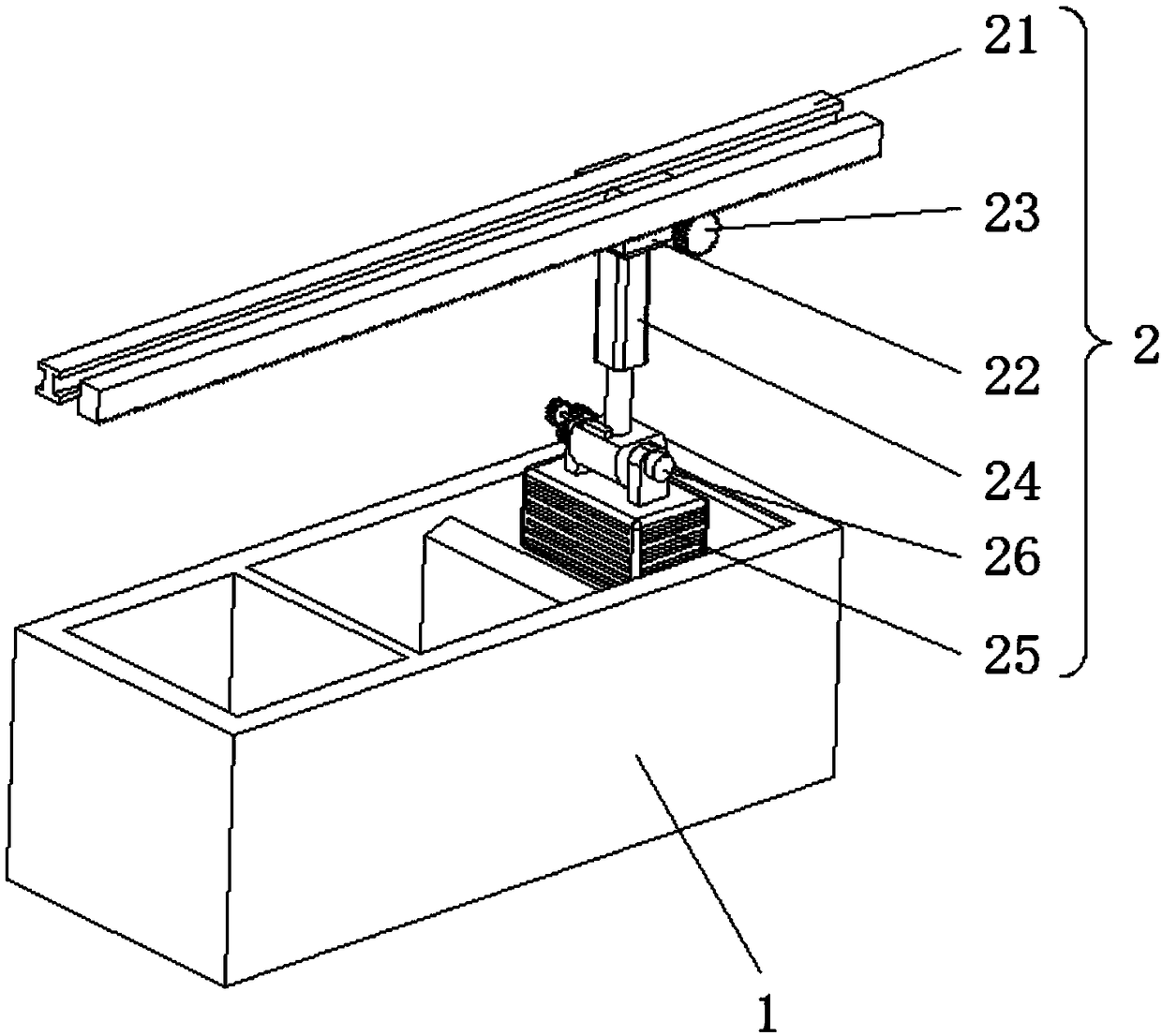

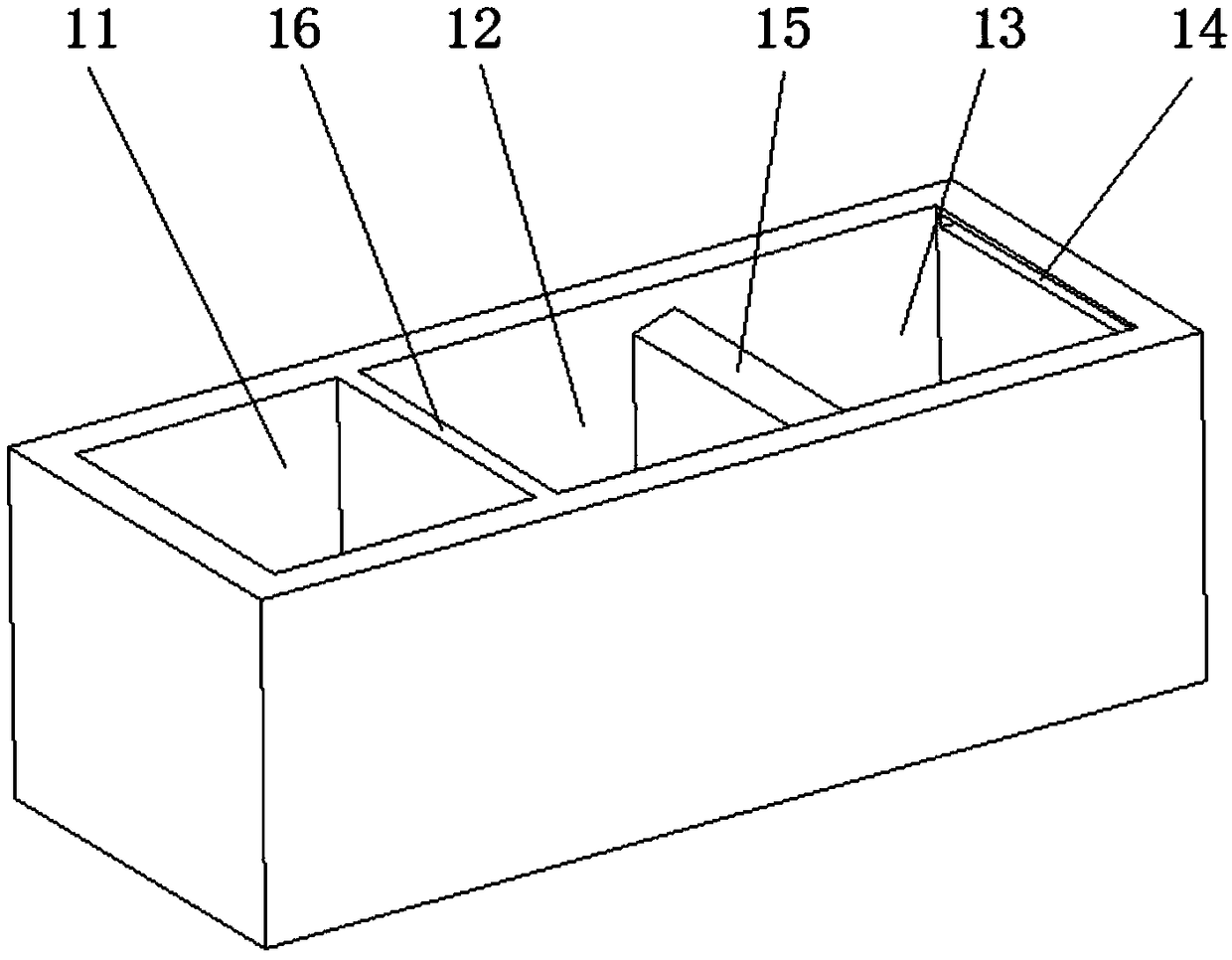

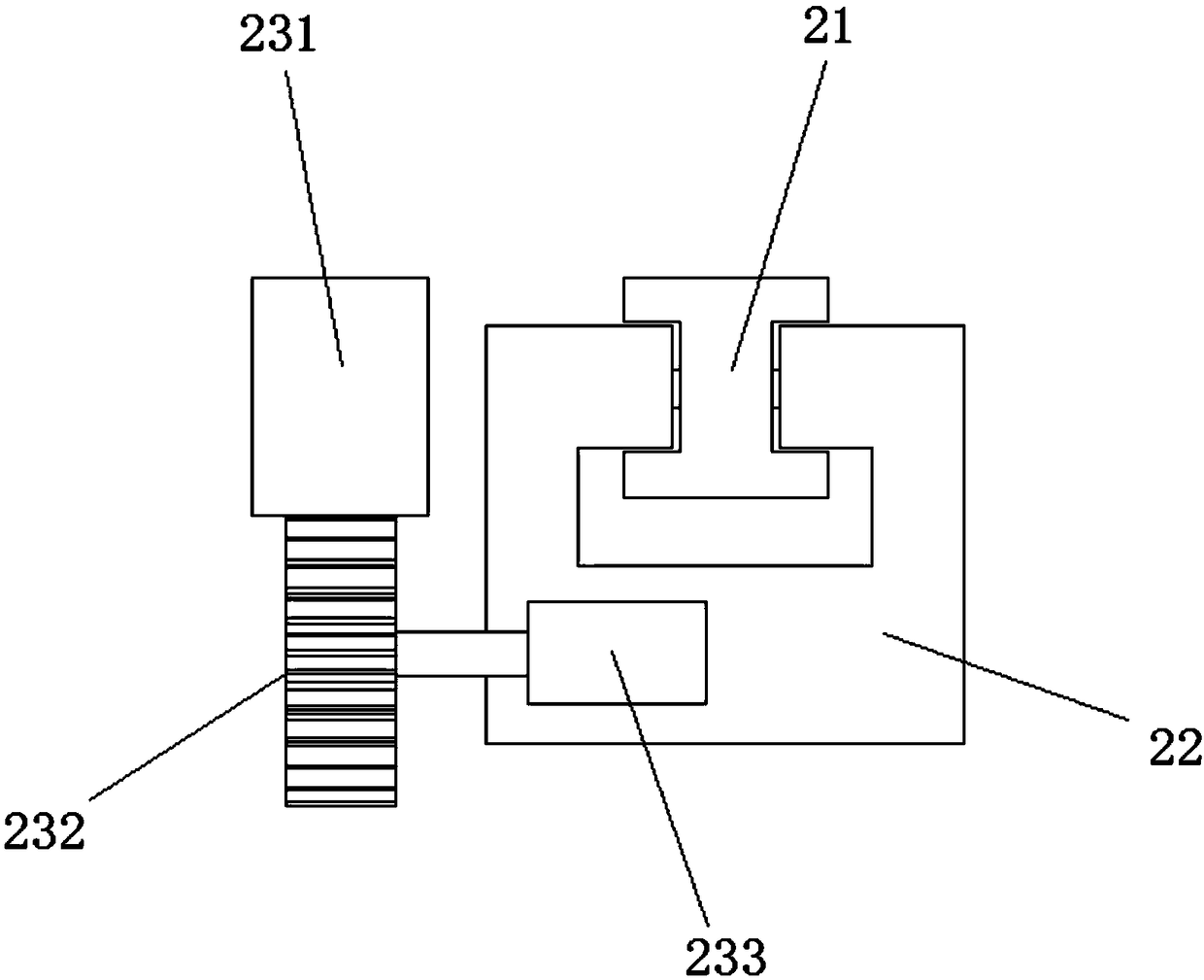

[0025] See Figure 1 to Figure 4 , the present invention has a cleaning tank 1 and a feeding mechanism 2; the inside of the cleaning tank 1 is sequentially separated from left to right with a degreasing tank body 11, a first rinsing tank body 12 and a second rinsing tank body 13; on the inner wall of the cleaning tank 1 A water inlet 14 connected to the water inlet is provided above the second rinsing tank 13; the water inlet 14 is located on the right side of the second rinsing tank 13; the first rinsing tank 12 is provided with a water outlet connected to the drain pipe; The upper edge of a rinsing tank body 12 is connected with the upper edge of the second rinsing tank body 13 through a water diversion slope 15; the upper edge of the second rinsing tank body 13 is higher than the upper edge of the first rinsing tank body 12; A water retaining plate 16 is provided between a rinsing tank body 12 and the oil removal tank body 11; The extension direction extends.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com