A Method of On-line Measuring Slab Width

A slab and width technology, applied in the field of online measurement of slab width, can solve the problems of affecting delivery cycle, increasing rolling cost, and stopping production of rolling line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

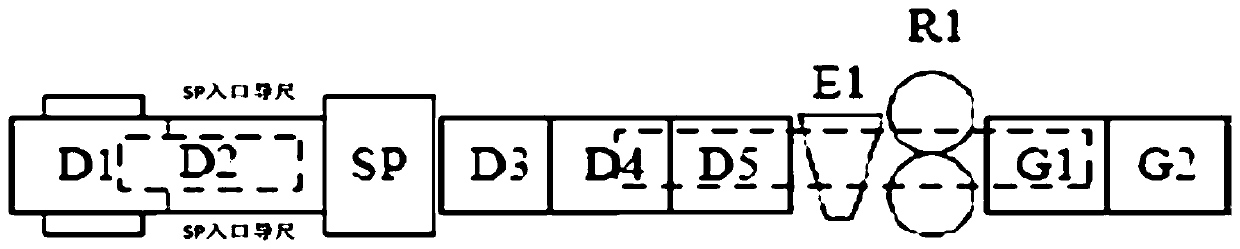

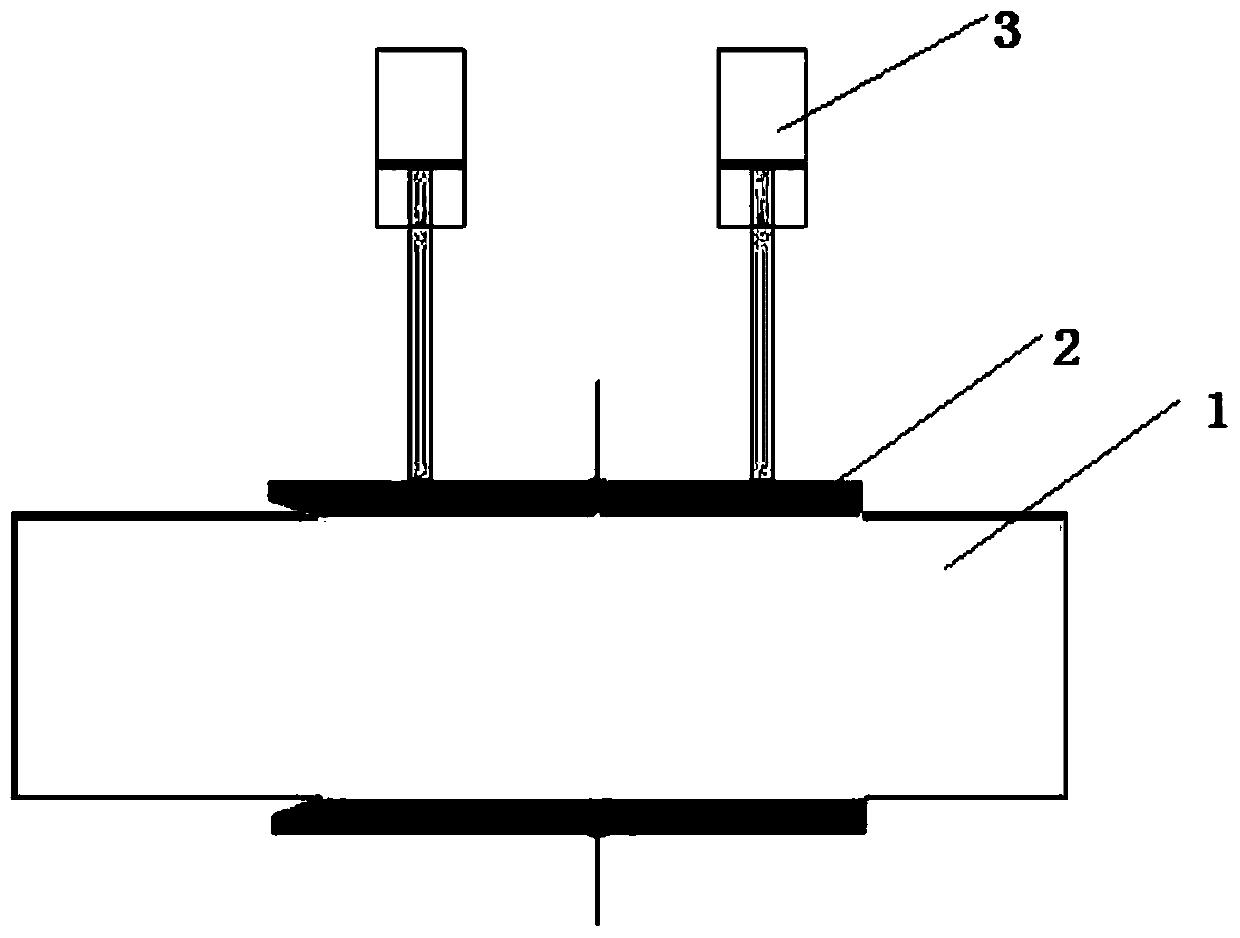

[0036] Such as Figure 1-2 As shown, a method for measuring the width of a slab online includes a pressure-width detection method, a displacement-width detection method and a slab width out-of-tolerance judgment method. The slab width is measured online by the pressure-width detection method or the displacement-width detection method, and the measurement result is judged by the slab width out-of-tolerance judgment method.

[0037] One, described pressure-width detection method comprises the steps:

[0038] 1) Install a pressure sensor on the 3 plug side of the front gauge hydraulic cylinder of the fixed-width press SP;

[0039] 2) During the centering process of the slab 1, the value of the pressure sensor is detected, and the pressure value is sent to the PLC for judgment processing;

[0040] 3) When the pressure is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com