Cutting device of stone plate

A cutting device and stone slab technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems affecting the efficiency of stone slab cutting, insufficient stone slab fixing quality, and damage to the cutting wheel, so as to ensure the fixed quality and ease of use. The effect of promotion and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

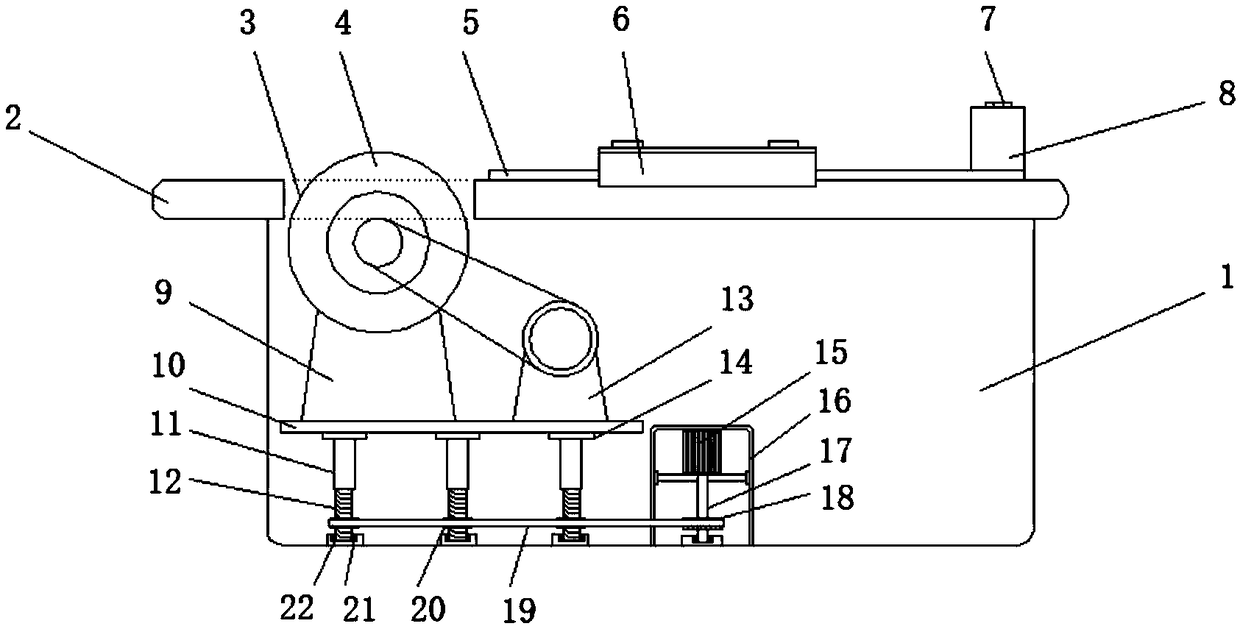

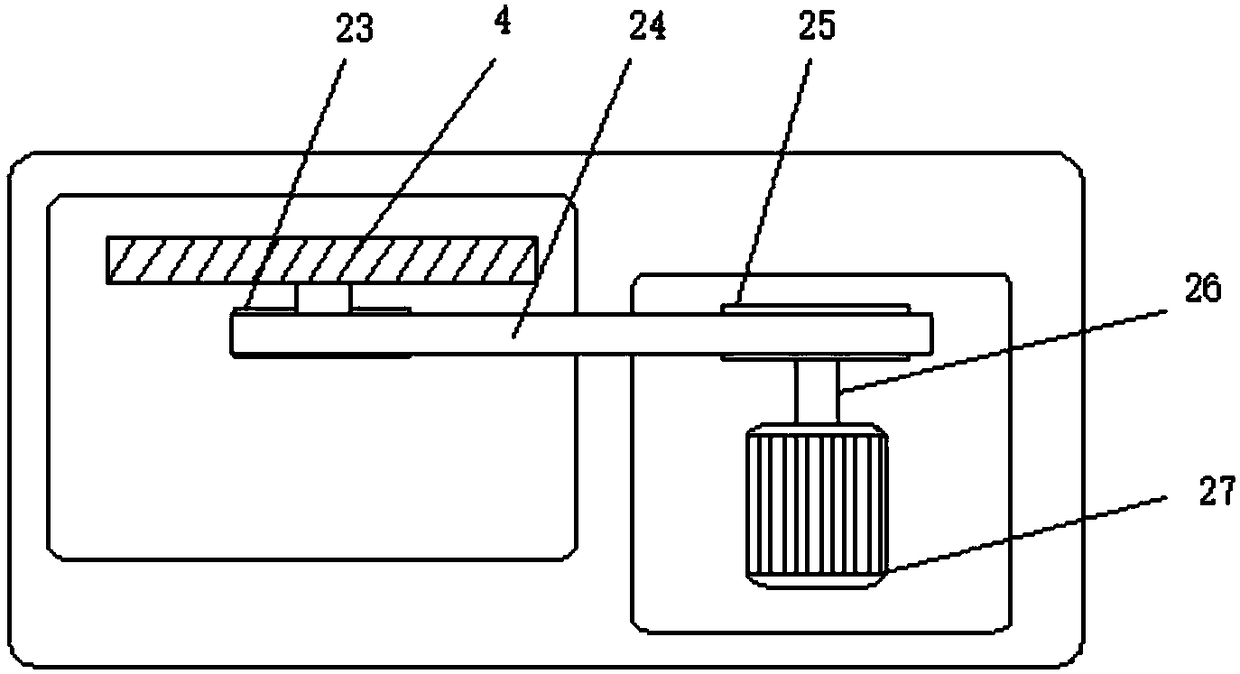

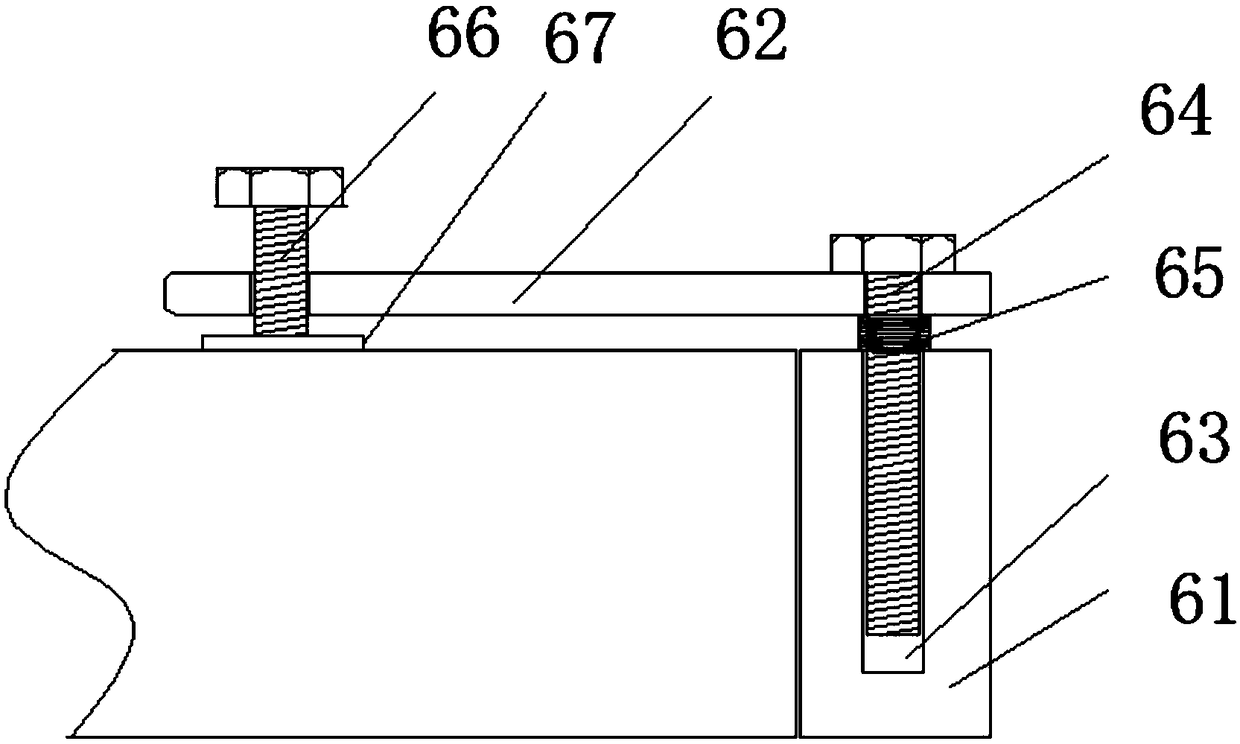

[0022] see Figure 1~3 , in an embodiment of the present invention, a slate cutting device includes a bottom box 1, a table 2 is fixedly installed on the upper end of the bottom box 1, a guide rail 5 is provided on the table 2, and a retractable cutter wheel is provided on one side of the guide rail 5. Hole 3, cutter wheel telescopic hole 3 is provided with 4, the cutter wheel 4 is connected to the cutting drive device, the lower end of the cutter wheel 4 and the cutting drive device is provided with an electric lifting device, and the cutter wheel can be adjusted by the electric lifting device 4, so that the cutting knife wheel 4 can adjust the appropriate distance from the telescopic hole 3 of the knife wheel according to the different thicknesses of the stone slabs, so as to avoid excessive useless gap between the cutting knife wheel 4 and the slit of the stone slab during the cutting process. Friction, while protecting the cutting wheel 4, can effectively improve the cutti...

Embodiment 2

[0032] see Figure 1~3 , on the basis of Embodiment 1, the embodiment of the present invention upgrades the function of a slate cutting device, specifically:

[0033]The right end of the guide rail 5 is provided with a fixed push block 8, and the fixed push block 8 is provided with a positioning bolt 7. The fixed push block 8 is connected to an automatic propulsion device, and the automatic propulsion device stably promotes the slate to advance and cut. 8 When not in use, the fixed push block 8 is fixed on the guide rail 5 by the positioning bolt 7, and the automation and cutting efficiency of the slate cutting device are improved by the fixed push block 8 and the automatic propulsion device.

[0034] Preferably, the automatic propulsion device is a telescopic hydraulic rod.

[0035] It should be noted that the lifting motor 15 and the lifting rotating shaft 17 in this application are all applications of the prior art. In this application, a bottom box 1 is provided, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com