Automatic edge sticking device for filter element

A kind of welt and automatic technology, applied in the direction of cardboard items, etc., can solve the problems of unstable paper core and glue, multi-manual, troublesome adjustment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

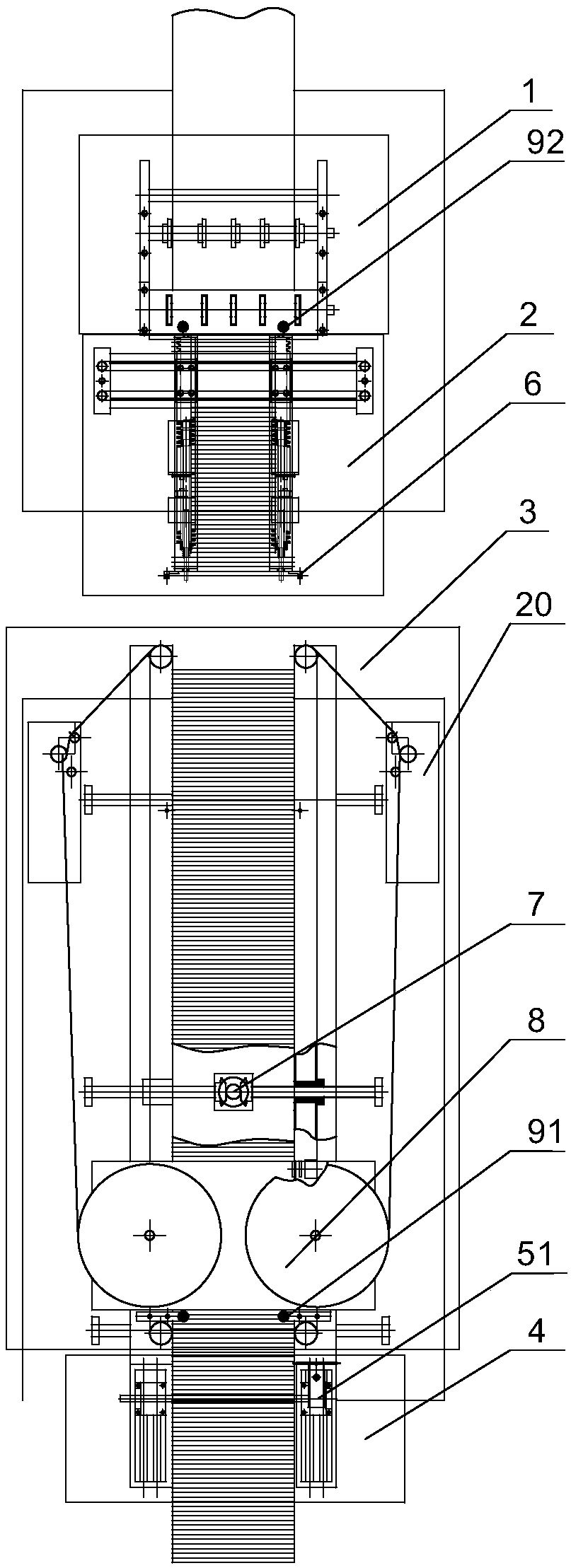

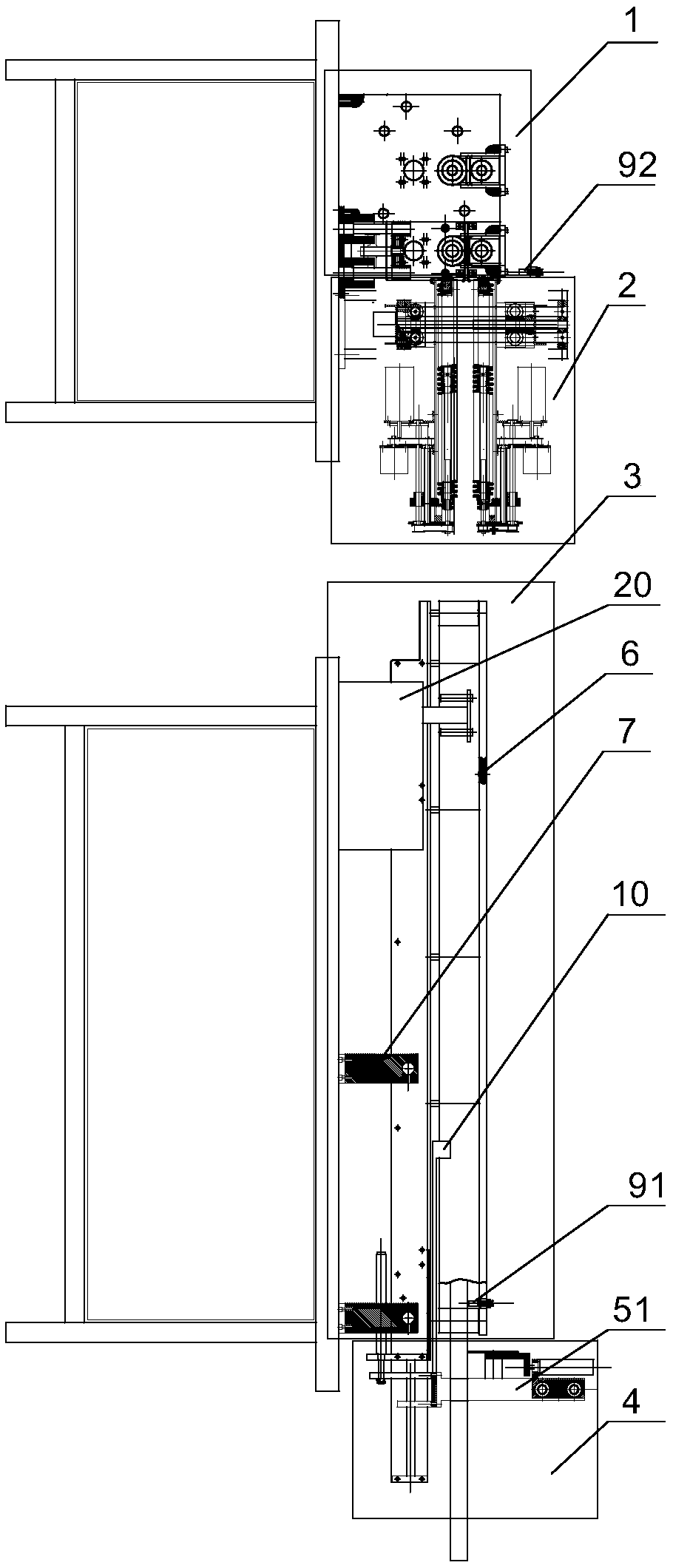

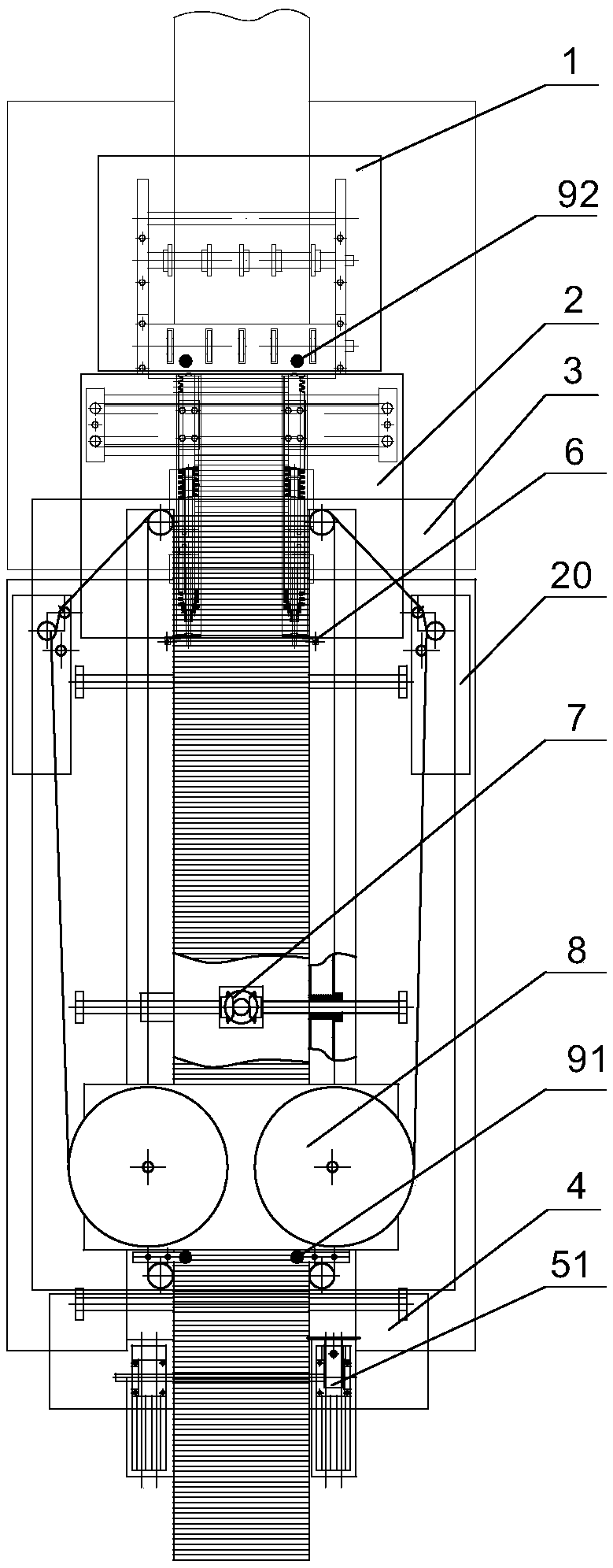

[0043] see Figure 1-Figure 9 As shown, the filter element automatic welting device of the present embodiment comprises a paper feeding device (1), a paper delivery device (2), a wetting device (3) and a cutting device (4), and the paper feeding device (1) transfers paper to be folded to The paper delivery device (2), the paper delivery device (2) sequentially transports the paper to the welting device (3) and the cutting device (4). When the paper delivery device (2) transports paper folds, the paper delivery device (2) collects the current paper fold evenly to form several paper folding units, and the edge sticking device (3) attaches edge strips to both sides of the current paper fold synchronously , the cutting device (4) cuts paper folds and side strips, and the rear section of the welting device (3) is provided with a rear paper folding sensing device (91) close to the cutting device (4), and a rear paper folding sensing device (91 ) to monitor the paper folding to cont...

no. 2 example

[0051] see Figure 13-Figure 16As shown, the specific structure of this embodiment is basically the same as that of the first embodiment, and the difference lies in the specific setting of the cutting device. Now, the filter element automatic edge wetting device of the second embodiment will be described. The filter element automatic welting device of the present embodiment comprises paper feeding device (1), paper delivery device (2), welting device (3), cutting device (4), same as the first embodiment, paper delivery device (2) ) is responsible for collecting the paper, and at the same time folds the paper evenly, and in the middle of the welting device (3) allows the side strips to be pasted according to the spacing of the paper delivery device (2). A rear paper folding induction device (91) is arranged near the two sides of the welting device (3) near the cutting device (4). When the rear paper folding sensing device (91) transmits the set number of folding signals to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com