Automatic control system for efficiently screening, sorting, loading and unloading cargoes and method thereof

An automatic control system, high-efficiency technology, applied in the direction of storage devices, transportation and packaging, etc., can solve the problems that affect the efficiency of automobile transshipment, the inability to realize high-efficiency automation, and the classification of goods, so as to reduce the workload of logistics classification and avoid tumbling scanning The effect of improving the degree of work and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

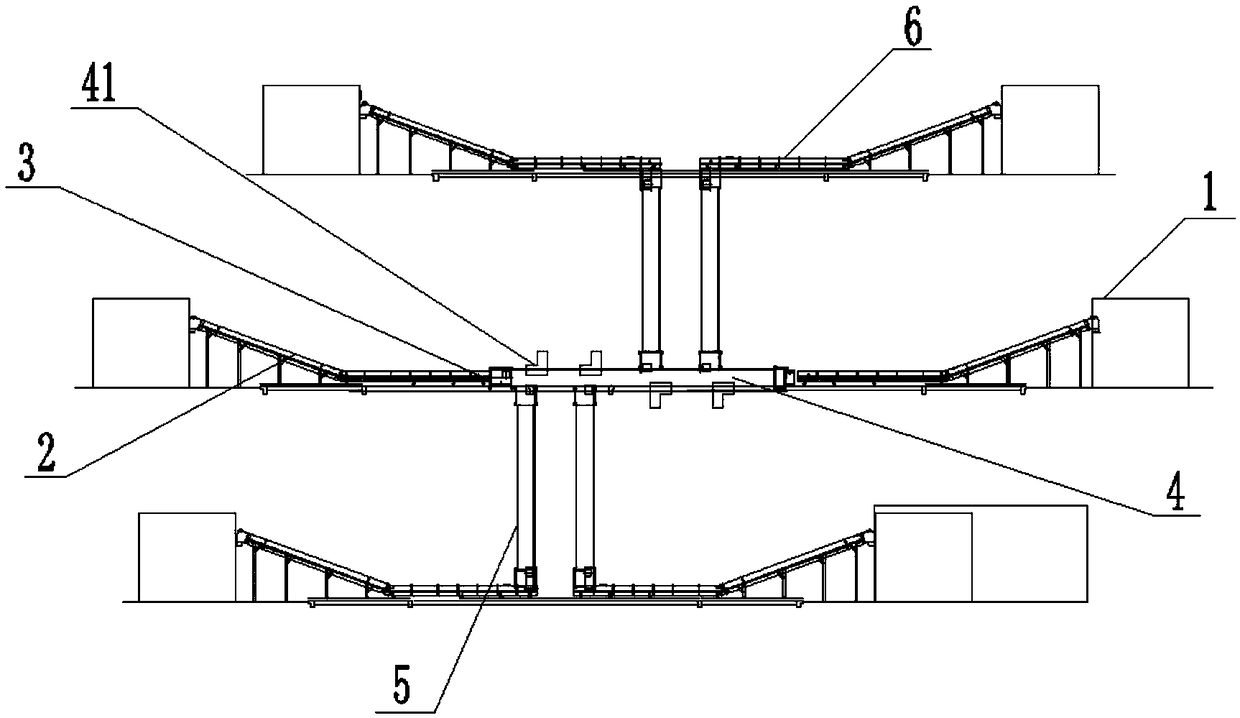

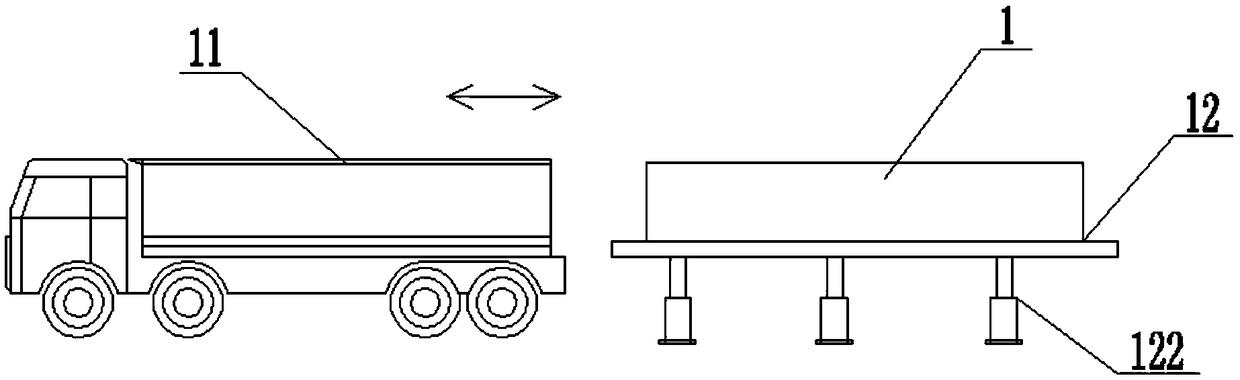

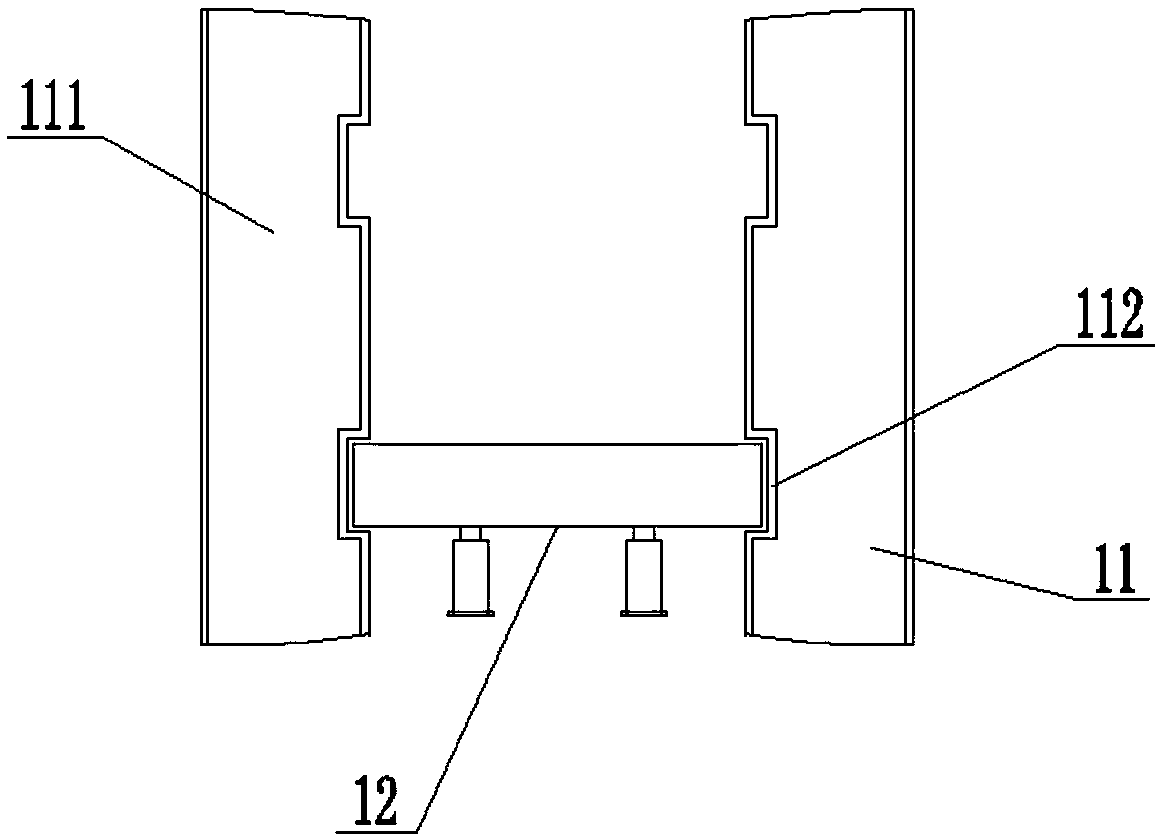

[0035] Such as Figure 1-6 As shown, the present invention discloses an automatic control system for efficient screening, sorting, loading and unloading, including a vehicle transfer system 1, an incoming channel 2, a scanning transmission system 3, a main channel 4, a sorting channel 5 and a shipping channel 6, A vehicle transfer system 1 is provided at the front end of the delivery channel 2, a cargo handling system is provided on the delivery channel 2 and the delivery channel 6, and a belt transmission system is provided on the delivery channel 2 and the delivery channel 6. device, the sorting channel 5 includes a conveyor belt, the scanning transmission system 3 is provided on the sorting channel 5, the rear end of the purchase channel 2 is connected to the front end of the main channel 4, and the main channel 4 The scanning transmission system 3 is provided, the goods pushing device 41 is fixedly installed on the side of the main passage 4, and a plurality of sorting pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com