Variable damping viscoelastic plate type damper

A viscoelastic, variable damping technology, applied in protective buildings/shelters, building components, shockproof, etc., can solve the problems of reducing the damping ratio of viscoelastic materials, accelerating material aging, deformation, etc., to optimize the utilization of materials, Fast repair and replacement, improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

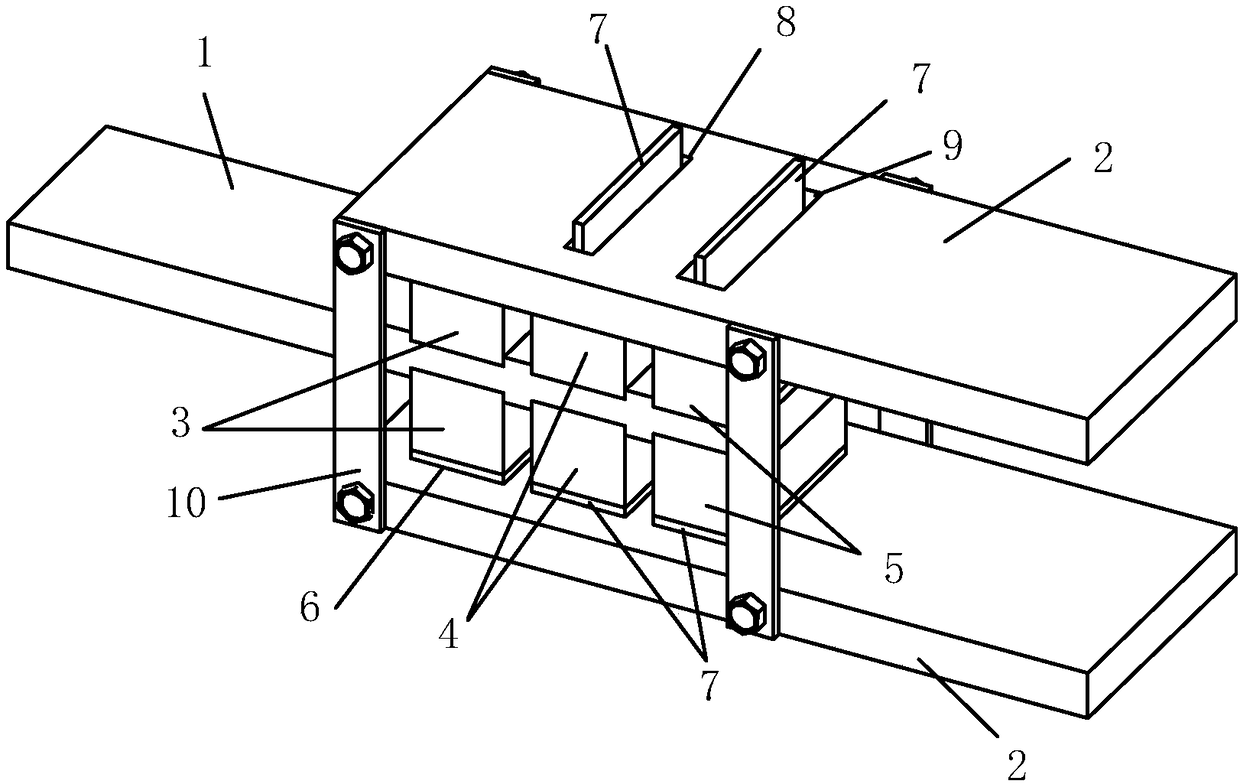

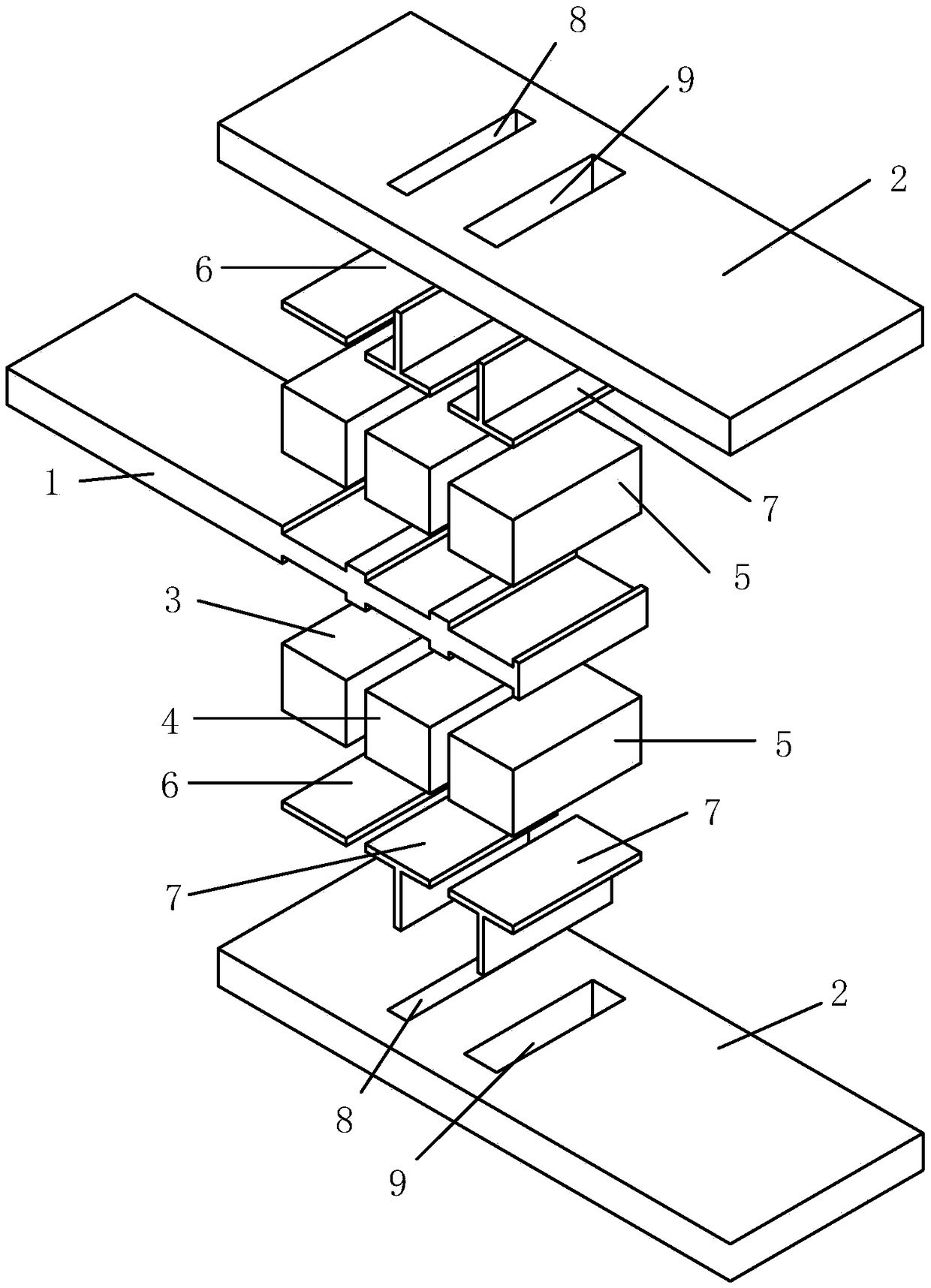

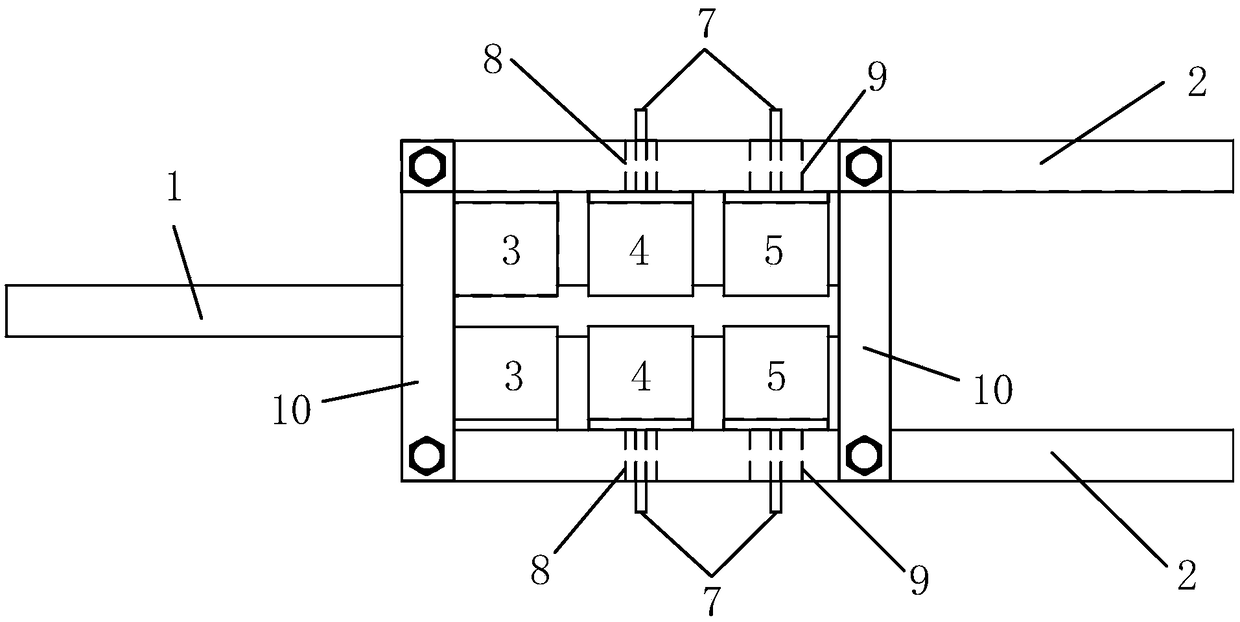

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as Figure 1~3 As shown, the variable damping viscoelastic plate damper of the present invention includes the outer steel plate 2 arranged up and down oppositely and the middle steel plate 1 between the two outer steel plates 2, and the outer steel plate 2 is provided with a plurality of square hole structures along the horizontal direction; It includes multiple groups of damping units arranged side by side (the present invention adopts three groups of damping units arranged side by side, namely damping unit I3, damping unit II4 and damping unit III5), each group of damping units includes a damping unit located above the middle steel plate and a damping unit located in the middle The damping unit below the steel plate, the two damping units in each group of damping units are symmetrically distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com