Roof waterproof roll baking device

A waterproofing membrane and baking technology, which is applied to tools for roofing, roofing, construction, etc., can solve problems such as affecting the quality of waterproofing construction, poor adhesion between the membrane surface and the roof, and high labor intensity. The effect is high efficiency, simple structure, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

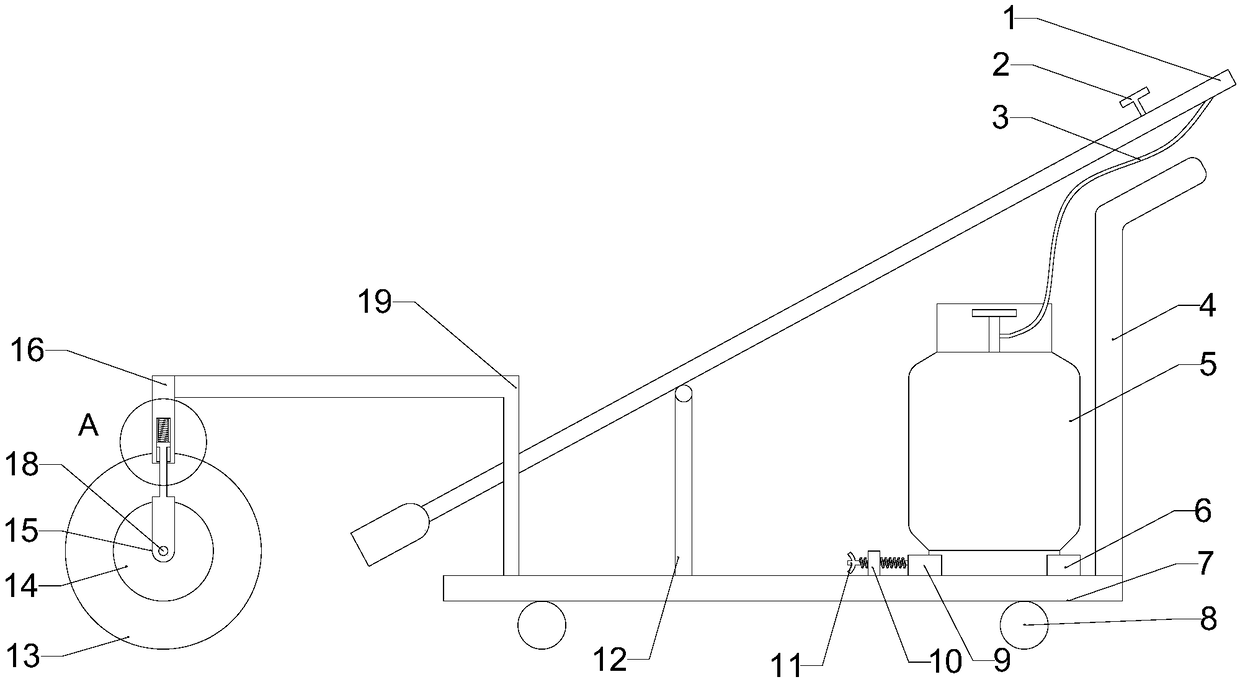

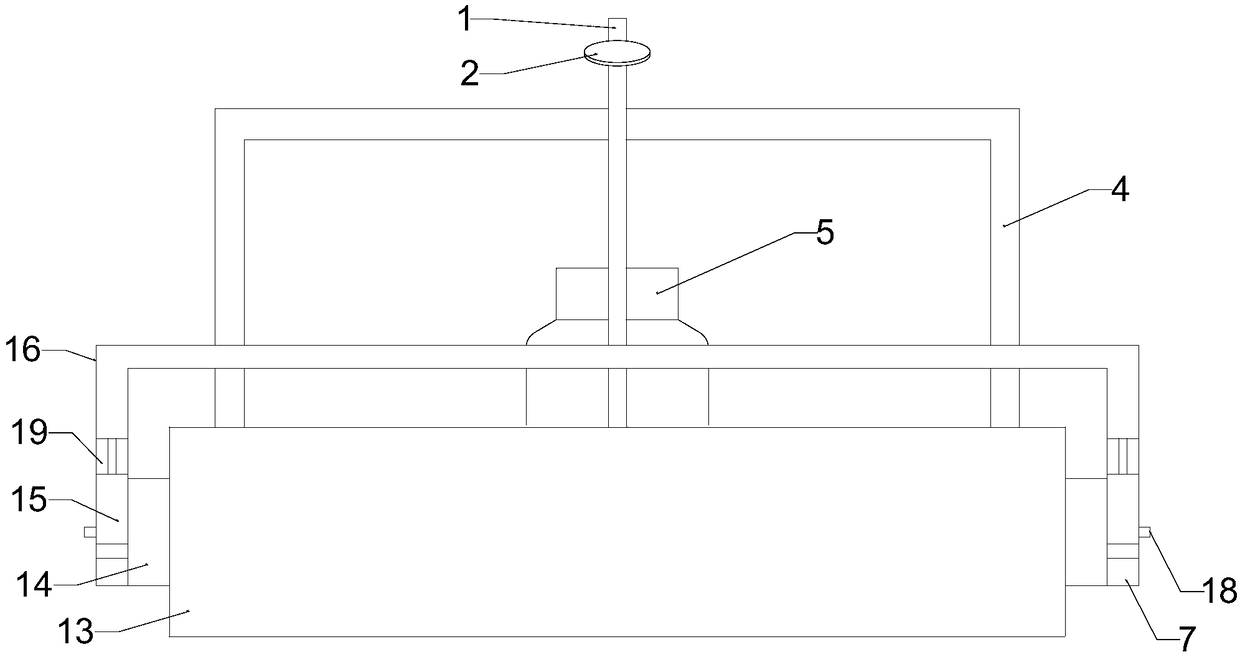

[0030] see Figure 1~3 , a roof waterproof membrane baking device, including a flame baking mechanism, the flame baking mechanism includes a flame spray gun 1 and a liquefied gas tank 5, the flame baking mechanism is arranged on a bottom plate 7, and the right side of the bottom plate 7 is vertically provided with a propulsion The handle 4 is provided with a pulley 8 at the four corners of the base plate 7, and the left side of the base plate 7 is provided with a waterproof roll laying mechanism.

[0031] In the present invention, the flame roasting mechanism set on the base plate 7 melts and softens the surface of the waterproof material covered on the waterproof coiled material 13 laying mechanism, and pushes the whole device forward through the propulsion handle 4 vertically arranged on the right side of the base plate 7 to make it waterproof. The coiled material 13 laying mechanism lays the waterproof material on the roof along the traveling path of the device, thereby com...

Embodiment 2

[0033] see Figure 1~3 , a roof waterproof membrane baking device, including a flame baking mechanism, the flame baking mechanism includes a flame spray gun 1 and a liquefied gas tank 5, the flame baking mechanism is arranged on a bottom plate 7, and the right side of the bottom plate 7 is vertically provided with a propulsion The handle 4 is provided with a pulley 8 at the four corners of the base plate 7, and the left side of the base plate 7 is provided with a waterproof roll laying mechanism.

[0034] The flame roasting mechanism includes a support rod 12 vertically arranged on the bottom plate 7, the ball on the upper part of the support rod 12 is hinged with a flame spray gun 1, the upper right side of the flame spray gun 1 is provided with a control valve 2, and the right end of the flame spray gun 1 is connected with a hose 3, The other end of the hose 3 is connected to the outlet of the liquefied gas tank 5 , and the liquefied gas tank 5 is arranged on the bottom plat...

Embodiment 3

[0039] see Figure 1~3 , a roof waterproof membrane baking device, including a flame baking mechanism, the flame baking mechanism includes a flame spray gun 1 and a liquefied gas tank 5, the flame baking mechanism is arranged on a bottom plate 7, and the right side of the bottom plate 7 is vertically provided with a propulsion The handle 4 is provided with a pulley 8 at the four corners of the base plate 7, and the left side of the base plate 7 is provided with a waterproof roll laying mechanism.

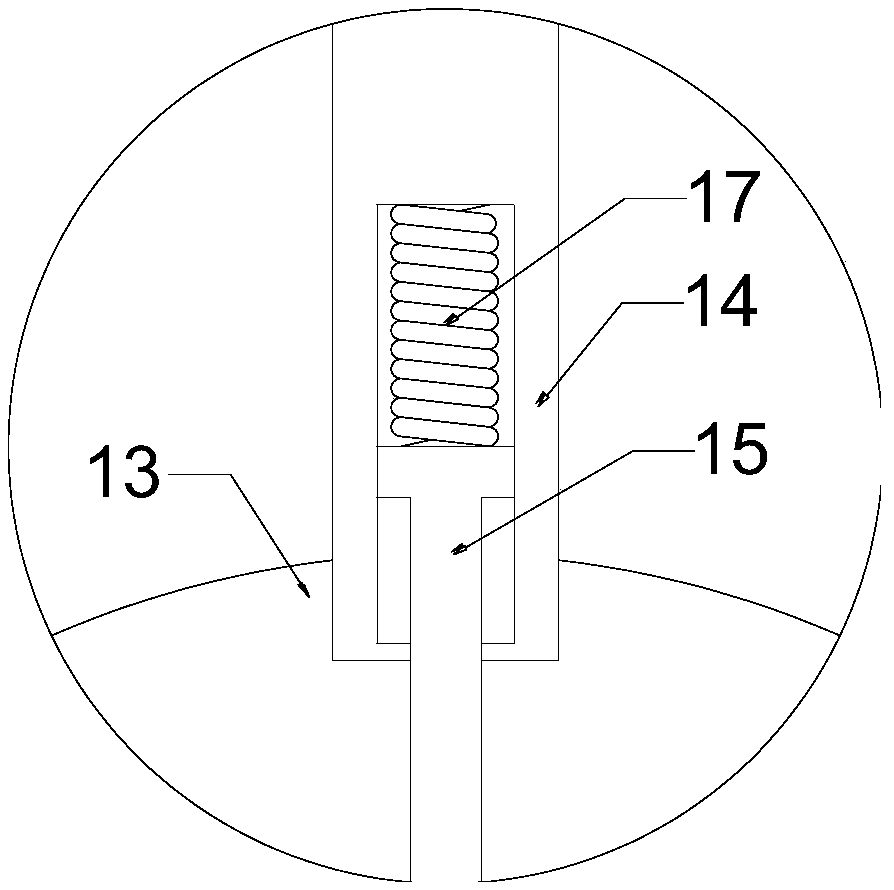

[0040] The laying mechanism of the waterproof coiled material 13 includes a support 19 located on the left side of the base plate 7, the left end of the support 19 is provided with a connecting cross bar 16, and the bottom of the connecting cross bar 16 is vertically provided with two splints 15, and the two splints 15 are connected by pin shafts 18. The roller 14 is covered with a waterproof coiled material 13 . By setting the waterproof membrane laying mechanism, the baking and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com