Automatic high-precision adjustment control system for common electric valve

A technology of regulating control and electric valves, applied in the direction of valve details, valve lifts, valve devices, etc., can solve problems such as limited adjustment accuracy, inability to output analog signals, and inability to achieve millisecond-level adjustments, so as to reduce response errors and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

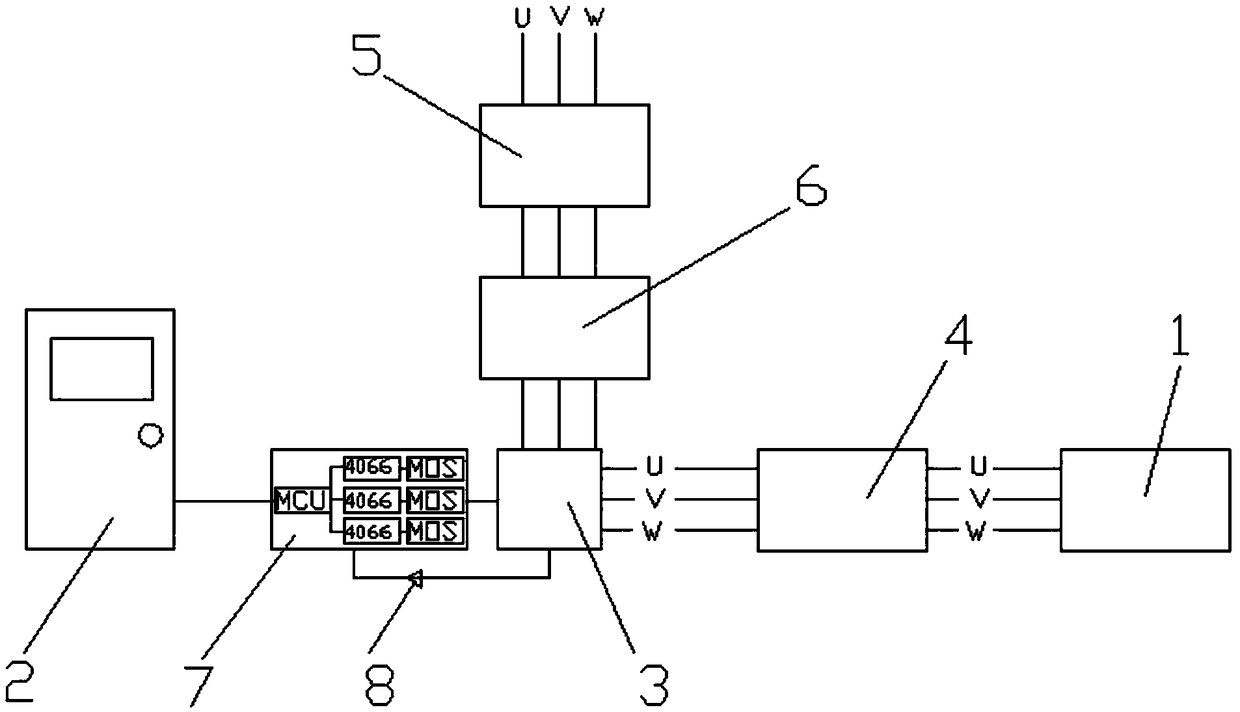

[0024] Such as figure 1 As shown; an ordinary electric valve realizes automatic high-precision adjustment control system, which is applied to a cold and hot continuous supply system, and is characterized in that it includes:

[0025] The electric valve 1, the electric valve 1 is installed in the cooling and heating continuous supply system, and the temperature sensor, pressure sensor and flow sensor are respectively installed in the cooling and heating continuous supply system,

[0026] DCS control cabinet 2, the temperature sensor, pressure sensor and flow sensor are respectively electrically connected to the input terminals of the DCS control cabinet,

[0027] Relay 3, electric valve 1 is connected to the output circuit of relay 3, and the input circuit of relay 3 is connected to the output terminal of DCS control cabinet 2,

[0028] A circuit protection module 4 is electrically connected between the connection between the electric valve 1 and the relay 3, and the output ci...

Embodiment 2

[0038] Such as figure 1 As shown; an ordinary electric valve realizes automatic high-precision adjustment control system, which is applied to a cold and hot continuous supply system, and is characterized in that it includes:

[0039] The electric valve 1, the electric valve 1 is installed in the cooling and heating continuous supply system, and the temperature sensor, pressure sensor and flow sensor are respectively installed in the cooling and heating continuous supply system,

[0040] DCS control cabinet 2, the temperature sensor, pressure sensor and flow sensor are respectively electrically connected to the input terminals of the DCS control cabinet,

[0041] Relay 3, electric valve 1 is connected to the output circuit of relay 3, and the input circuit of relay 3 is connected to the output terminal of DCS control cabinet 2,

[0042] A circuit protection module 4 is electrically connected between the connection between the electric valve 1 and the relay 3, and the output ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com