Air bag pipe sealing element

A pipeline sealing, airbag technology, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problem of increasing groundwater leakage, and achieve the effect of improved sealing performance, compact structure and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

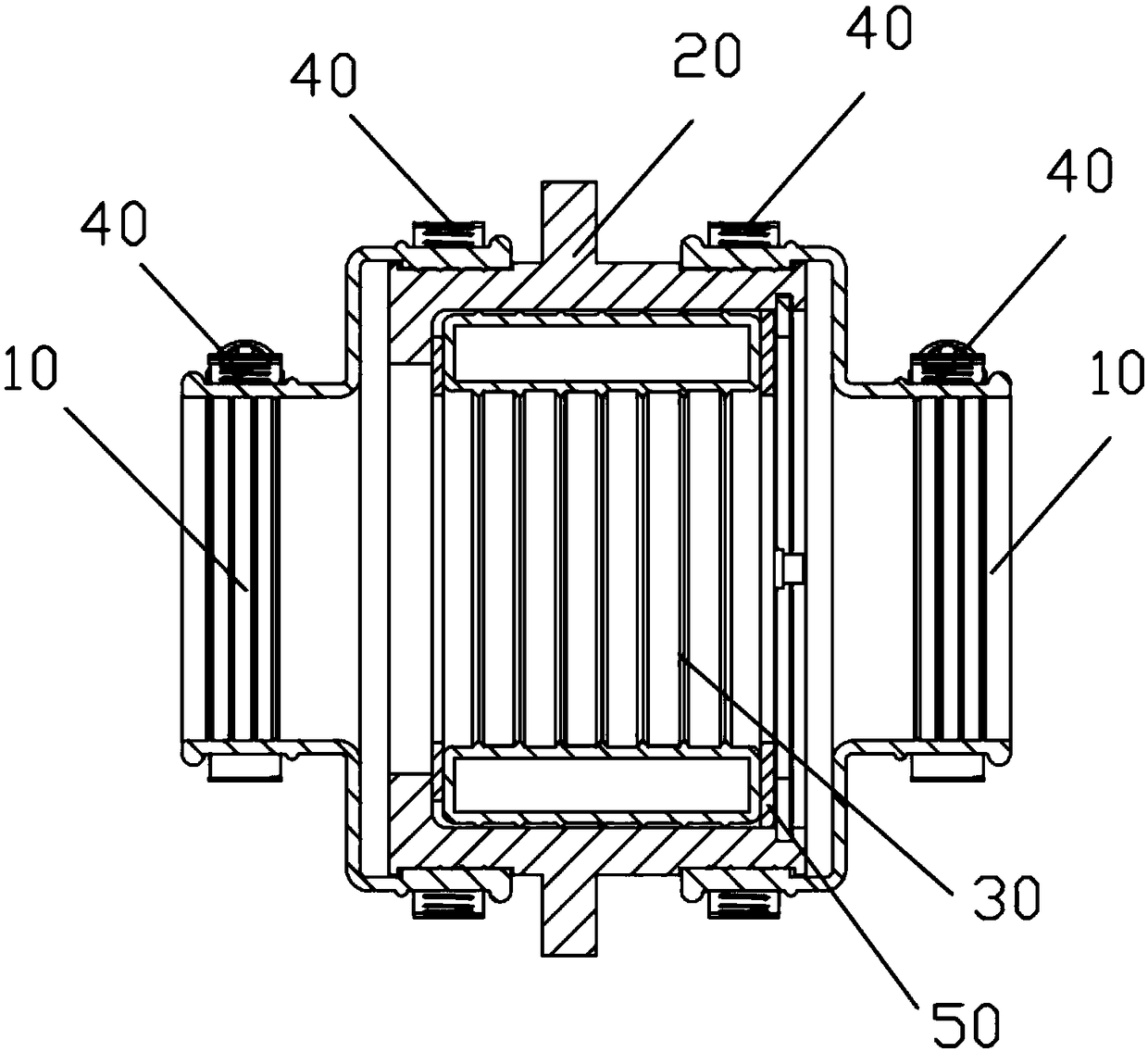

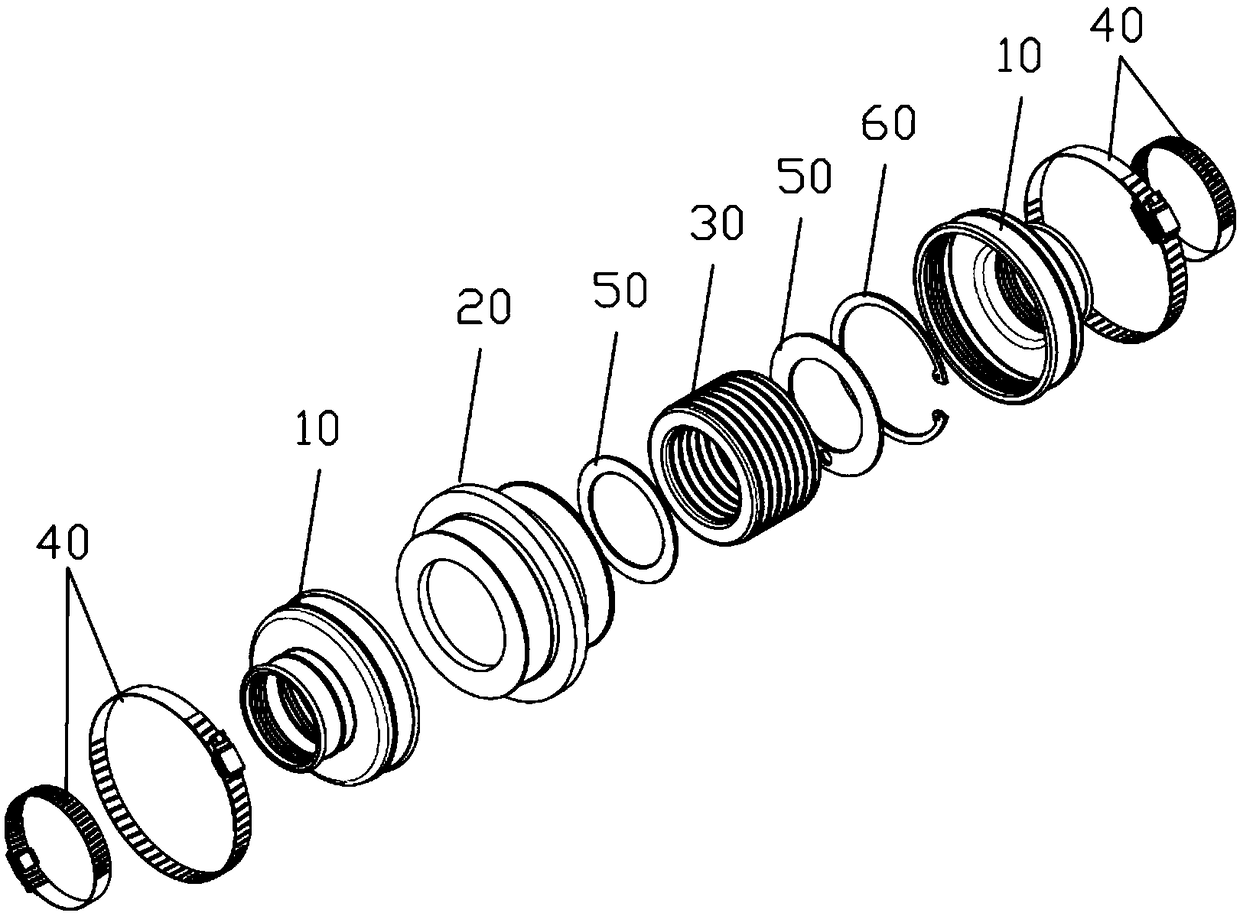

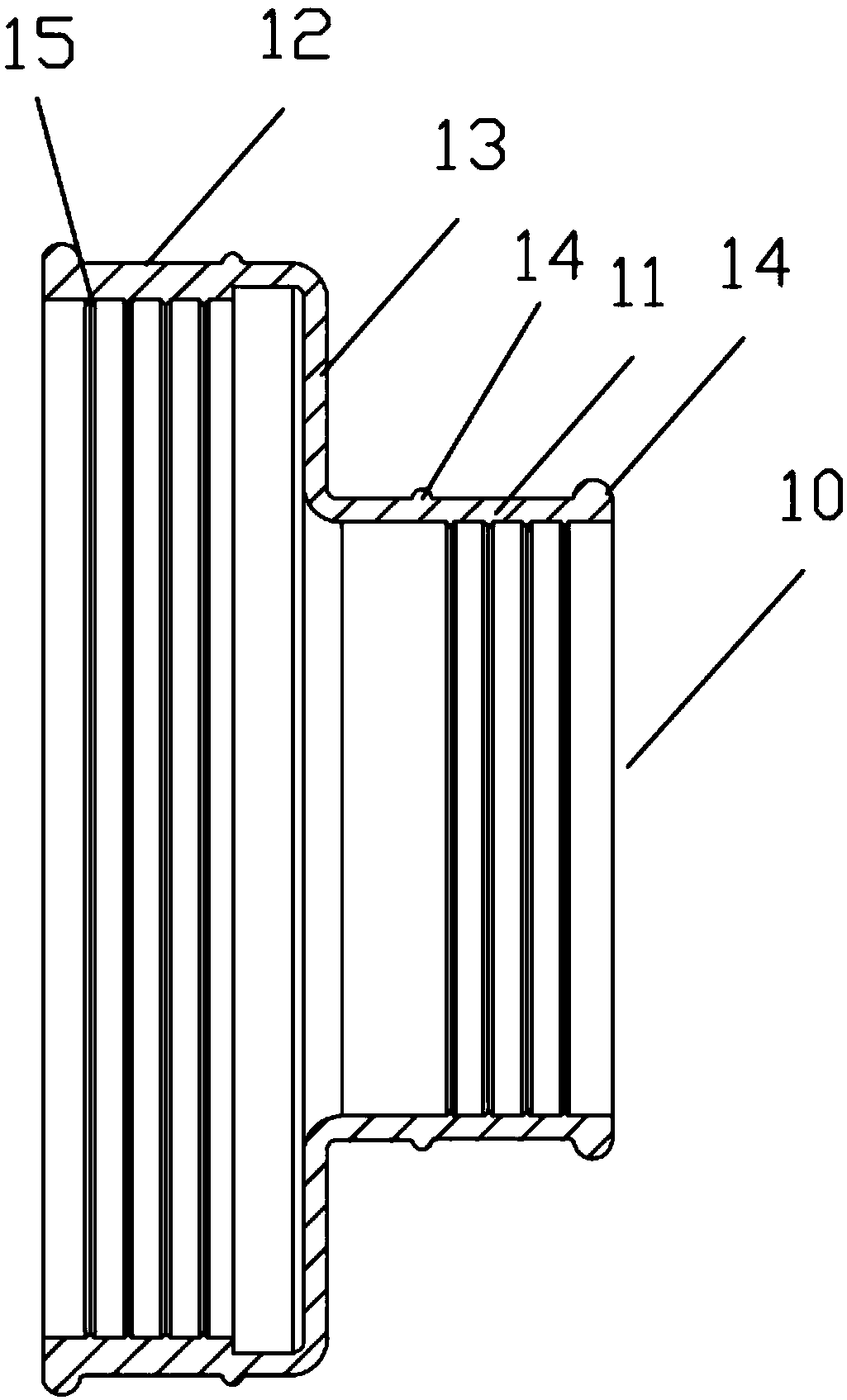

[0025] Example: such as Figure 1-7 As shown, a gas bag-type pipe seal includes a sealing sleeve 10, a sealing flange 20 and an air bag 30, the sealing flange 20 is fixedly connected to the opening of the underground container 70, and penetrates from the outside of the underground container To the inner side of the underground container, the underground pipeline 80 is passed through the inside of the sealing flange 20, and an accommodating groove 21 is provided between the underground pipeline 80 and the sealing flange, and the air bag 30 is placed in the accommodating groove 21 and sealed. Sleeved on the underground pipeline 80, a sealing sleeve 10 is respectively sleeved on the sealing flange 20 located inside and outside the underground container, and the sealing sleeve 10 is used to seal the gap between the sealing flange and the underground pipeline 80. The sealing sleeve 10 is an integral rubber part, and the sealing flange 20 is an integral polyethylene part. The seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com