Mountain crack monitoring and early warning system and early warning method

A technology of monitoring and early warning, mountain, applied in the field of crack monitoring device, monitoring and early warning system of mountain crack deformation, can solve the problem of high professional quality requirements of operators, monitoring timeliness, economy, operability, and structural reliability. Problems such as balance points, inability to obtain data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

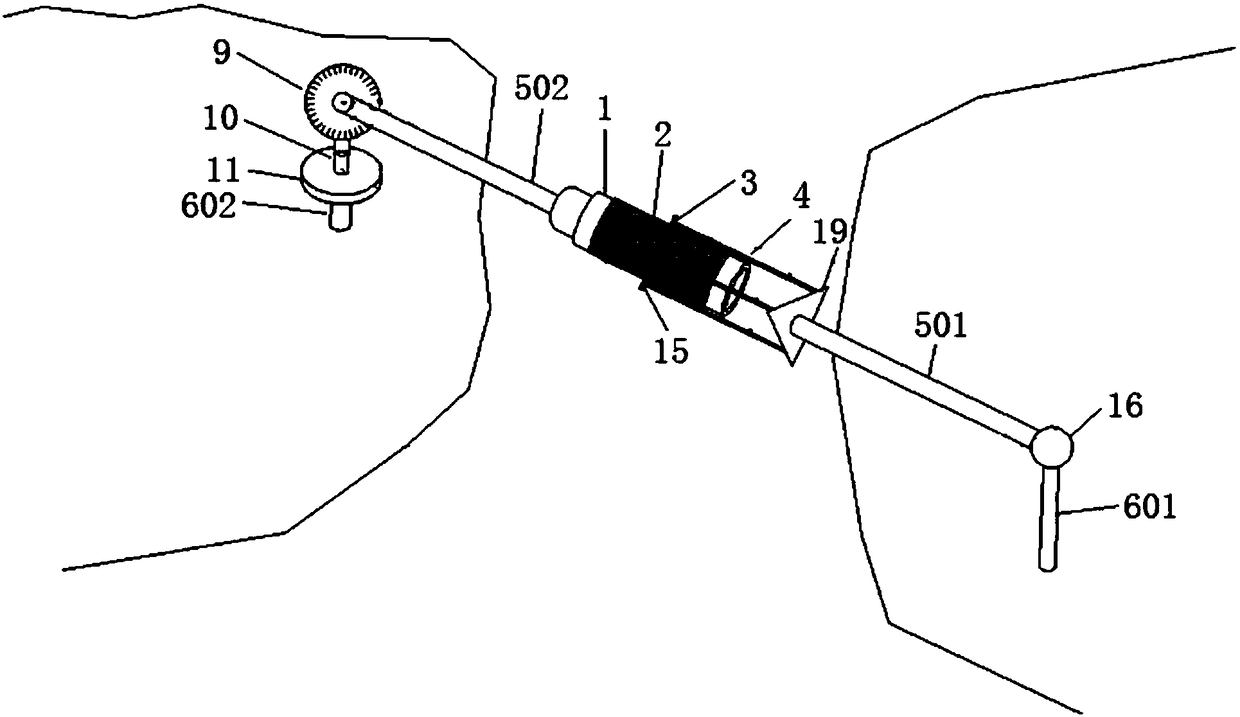

[0131] like figure 1 As shown, a mountain crack monitoring and early warning system, the system includes: an insulating wire barrel 1, a resistance wire 2, a metal slide 3, a metal connecting rod 4, a first non-metallic support rod 501, a second non-metallic support rod 502, A first fixed rod 601 , a second fixed rod 602 , an ammeter 7 , an angle processor 8 , a vertical angle sensor 9 , a pillar 10 , a horizontal angle sensor 11 , and a power supply 12 .

[0132] The resistance wire 2 is wound on the insulating wire barrel 1 . The metal connecting rod 4 is arranged on the periphery of the insulating wire barrel 1 . One end of the metal connecting rod 4 is connected with the metal slide 3 . The metal slide 3 is in contact with the resistance wire 2 on the insulating wire barrel 1 . The first non-metal support rod 501 is connected to the other end of the metal connecting rod 4 and the first fixing rod 601 . The second non-metal support rod 502 connects the end of the insula...

Embodiment 2

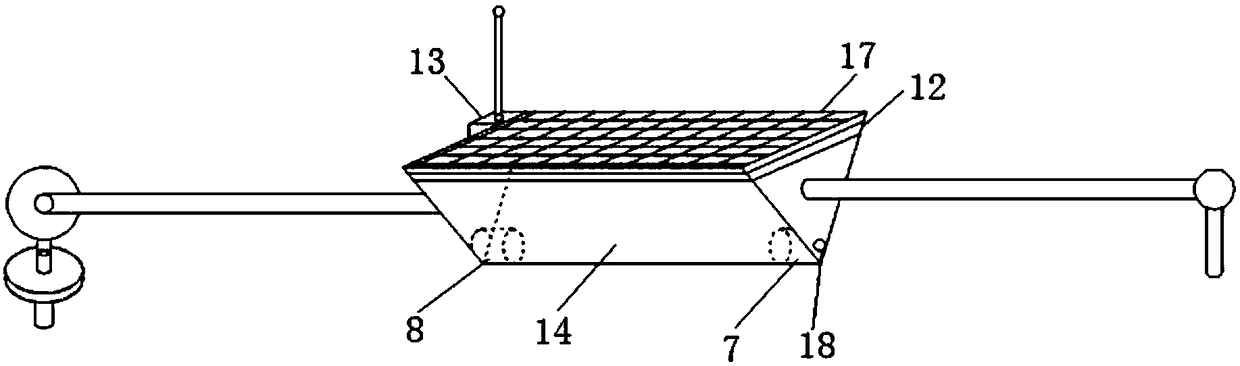

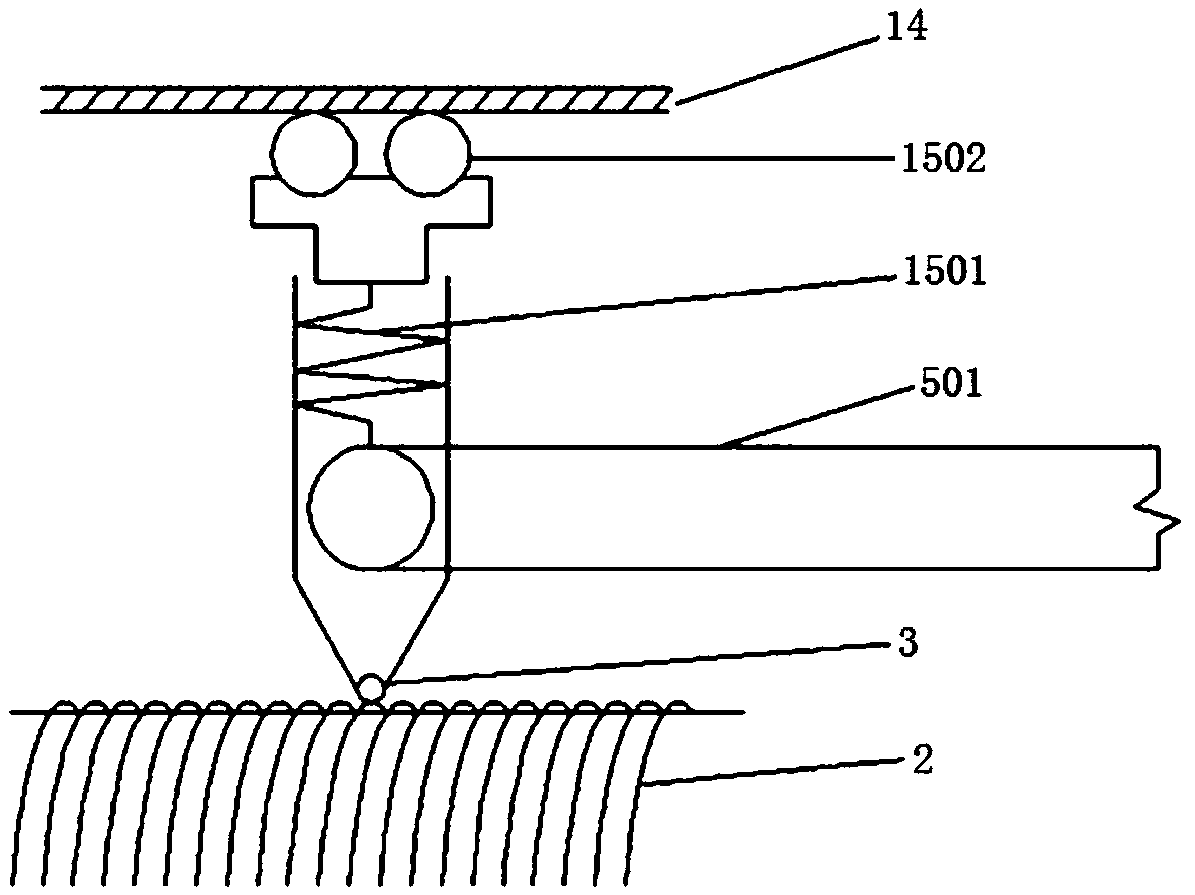

[0137] like figure 2 As shown, Embodiment 1 is repeated, except that the system further includes a wireless signal transmitter 13 . The wireless signal transmitter 13 is connected with the ammeter 7 and the angle processor 8 . The system also includes a housing 14 . The casing 14 wraps around the outside of the sliding rheostat K. The first non-metal support rod 501 and the second non-metal support rod 502 protrude from both ends of the housing 14 respectively. The system also includes a limit pulley 15 . The limit pulley 15 includes a spring 1501 and a pulley 1502 . The spring 1501 connects the pulley 1502 and the metal slide 3 on the sliding rheostat K, and the pulley 1502 is in contact with the inner wall of the housing 14 . The system also includes a steering knuckle 16 . The steering knuckle 16 is disposed at the connection between the first non-metallic support rod 501 and the first fixed rod 601 , and is used for adjusting the angle between the first non-metallic...

Embodiment 3

[0139] Embodiment 2 is repeated, except that the system further includes a protection resistor 18 . The protection resistor 18 is connected in series in the first closed loop. The system also includes a tripod mount 19 . The metal connecting rod 4 is connected with the first non-metallic support rod 501 through the triangular fixing bracket 19 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com