A Method for Measuring the Cathode Proximity Focusing Distance of Super Second Generation Image Intensifier

A technology of focusing distance and image intensifier, which is applied in the direction of measuring device, instrument, optical instrument test, etc., to avoid economic loss and avoid the risk of breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

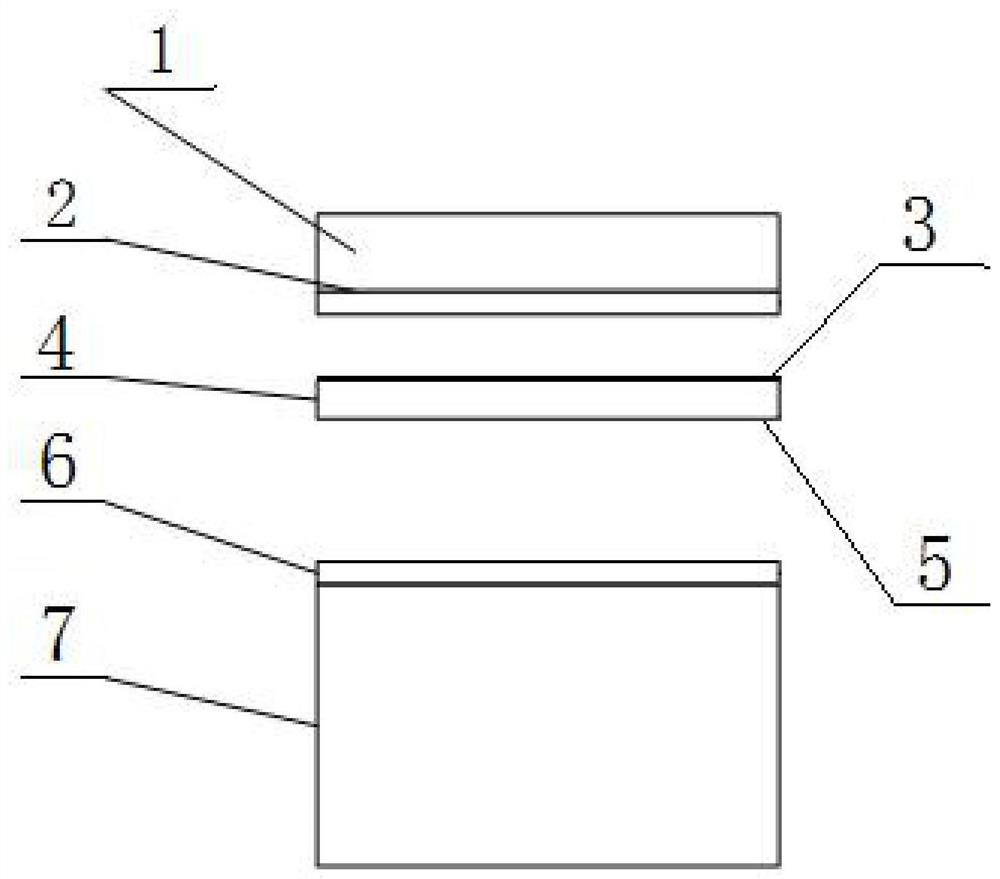

Embodiment 1

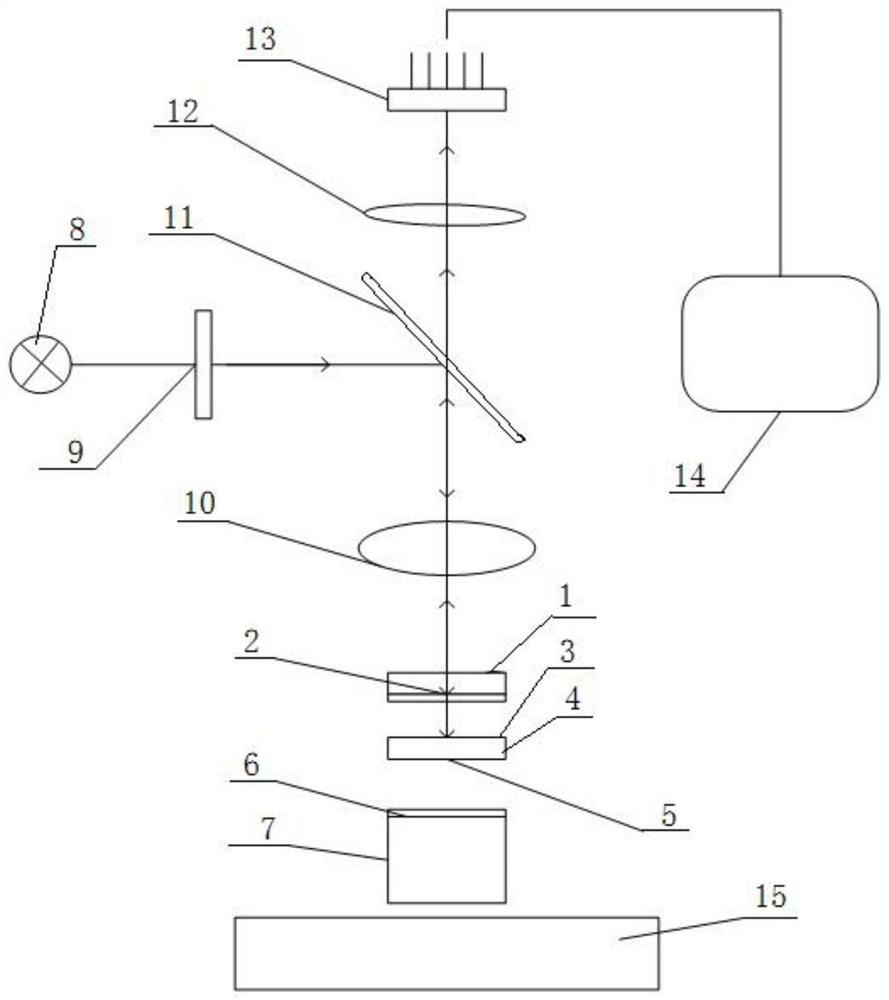

[0029] Use the method of the present invention to measure the close-fitting focus distance of the cathode of the image intensifier, such as figure 2 As shown, the objective lens 10, the half mirror 11, the eyepiece 12, and the CMOS device are fixed sequentially from bottom to top using a frame, and the CCD or CMOS device is connected to the computer 14, and the stage 15 is set to place the image intensifier at the same time. The table 15 can move in the X and Y directions in the plane; and a controller for the fine-tuning mechanism of the objective lens focus can be moved in the Z direction.

[0030] It includes the following steps: (1) Turn on the working power of the tungsten lamp, adjust the working current to the rated value, and let the current stabilize for 5 minutes. The interference filter used in the optical path is a 980nm interference filter.

[0031] (2) Turn on the working power of the CMOS device, turn on the computer 14, and make the CMOS camera work normally....

Embodiment 2

[0036] On the other hand, the present invention can also be used for measuring the distortion of image intensifier microchannel plate 4, comprises the steps:

[0037] (1) Turn on the working power of the tungsten filament lamp, adjust the working current to the rated value, and let the current stabilize for 5 minutes. The interference filter used in the optical path is a 980nm interference filter.

[0038] (2) Turn on the working power of the CMOS device, turn on the computer, and make the CMOS camera work normally. The target size of the CMOS device used is 1 inch, the resolution is 800H×600V, and the frame frequency is 25Hz. Place an image intensifier with an effective cathode diameter of Φ40mm on the stage 15 of the measuring device, with the photocathode facing upwards and facing the objective lens 10, while making the center of the photocathode coincide with the axis of the measuring device. The magnification of the objective lens 10 is 10 times.

[0039] (3) Adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com