The pie coil with the neutral point voltage regulating section in the middle

A pancake coil, neutral point technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve problems such as increasing cost, reduce loss, simplify coil structure, and avoid the danger of electrical breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

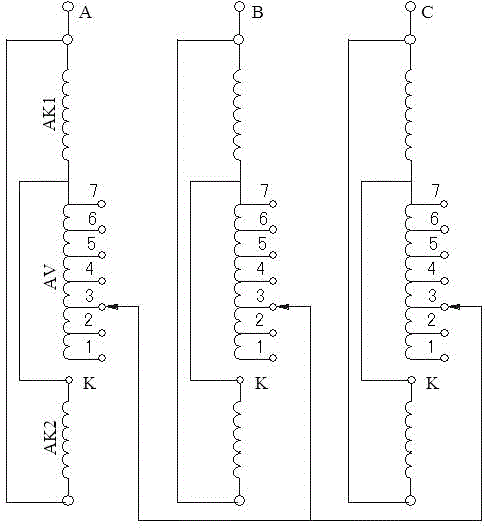

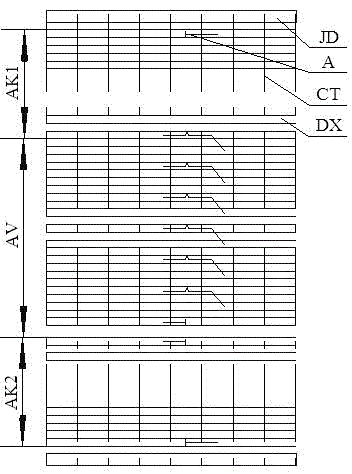

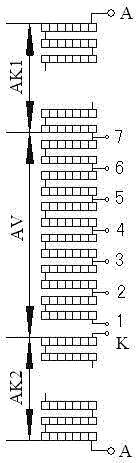

[0017] Embodiment one: if Figure 1~3 As shown, a pie-shaped coil with a neutral-point voltage-regulating section in the middle includes a basic section and a voltage-regulating section AV. The voltage regulating section AV is arranged in the middle of the coil, the voltage regulating section AV is connected in series at the end of the basic section, and part or all of the voltage regulating section AV participates in the operation of the transformer.

[0018] In Embodiment 1, the coil is wound on a frame made of struts CT and pads with a flat wire DX, and the number of the struts CT is uniformly distributed from 8 to 8 in the circumferential direction according to the size of the iron cores of the coil. 24 pieces; the two ends of the coil are respectively provided with insulating end coils JD, the ends of the coil are provided with end taps, and the middle part of the coil is provided with taps (1, 2, 3, 4, 5, 6, 7).

Embodiment 2

[0019] Embodiment two: if Figure 4~6 As shown, a pie-shaped coil with a neutral-point voltage-regulating section in the middle includes a basic section and a voltage-regulating section AV. The voltage regulation section AV adopts the parallel structure of the upper voltage regulation section AV1 and the lower voltage regulation section AV2 according to the large current requirements, the voltage regulation section AV is arranged in the middle of the coil, and the voltage regulation section AV is connected in series in the basic section At the end, part or all of the voltage regulating section AV participates in the operation of the transformer.

[0020] In Embodiment 2, the coil is wound on a frame made of struts CT and pads with a flat wire DX, and the number of struts CT is uniformly distributed from 8 to 8 in the circumferential direction according to the size of the iron cores of the coil. 24 pieces; the two ends of the coil are respectively provided with insulating end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com