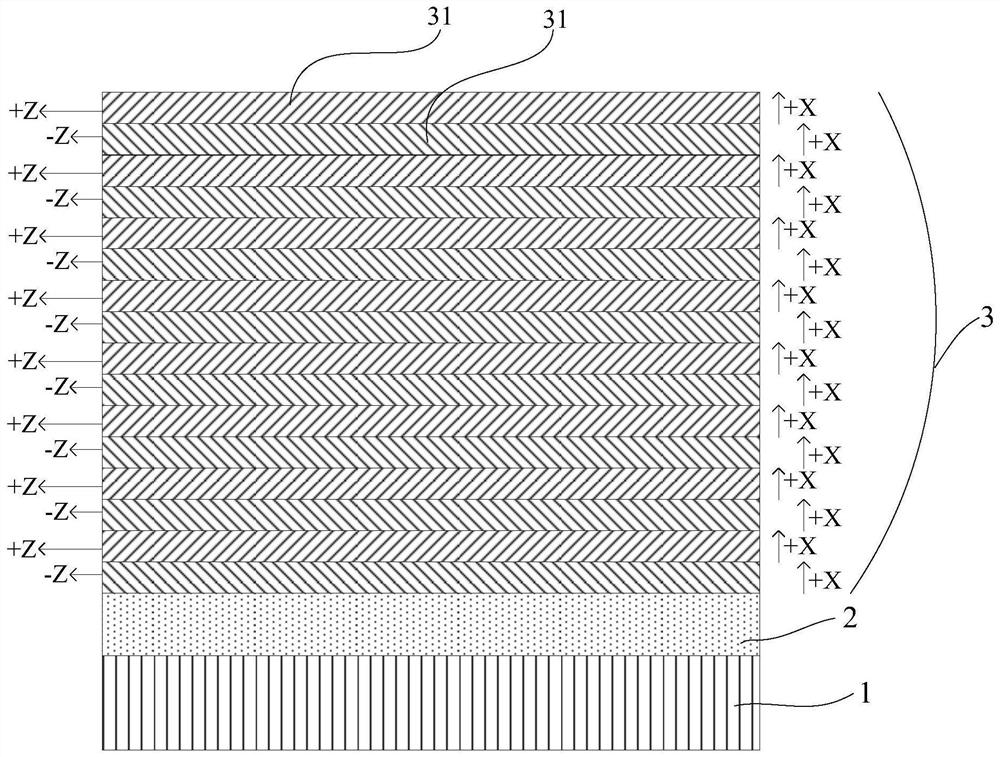

A kind of periodically polarized film substrate and its preparation method

A thin-film substrate and periodic polarization technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the limitation of the total length of the PPLN period , PPLN signal loss is large, the cycle length is difficult to achieve, etc., to achieve the effect of flexible control of the polarization cycle and cycle number, flexible and controllable thickness, and increase of the total cycle length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] (1) The preparation is 4 inches, the thickness is 0.5 mm and has a smooth surface of the smooth surface, wherein the silicon wafer is less than 0.5 nm, and the silicon substrate is cleaned, and the CVD method is used. The smooth surface of the silicon wafer is alternately deposited 2 layers of silicon oxide layer and a 2 layer nitride layer, each layer of silicon oxide layer and a silicon nitride layer having a thickness of 200 nm, and the silicon oxide layer and a silicon nitride layer. Co-constituting the buffer layer;

[0130] (2) The preparation of X-cracked x-cut is a lithium tissue wafer (for ease of description, "the first crystal circle", the large cutting direction is + z-axis direction, and there is from the large cutting direction as the -Z-axis direction) , Use ion implantation method, from -X face ion ions (HE + ) Inject the first wafer, HE + The injection energy is 200KEV, the dose is 4 × 10 16 IONS / cm 2 , The first wafer is formed to form a thin film layer,...

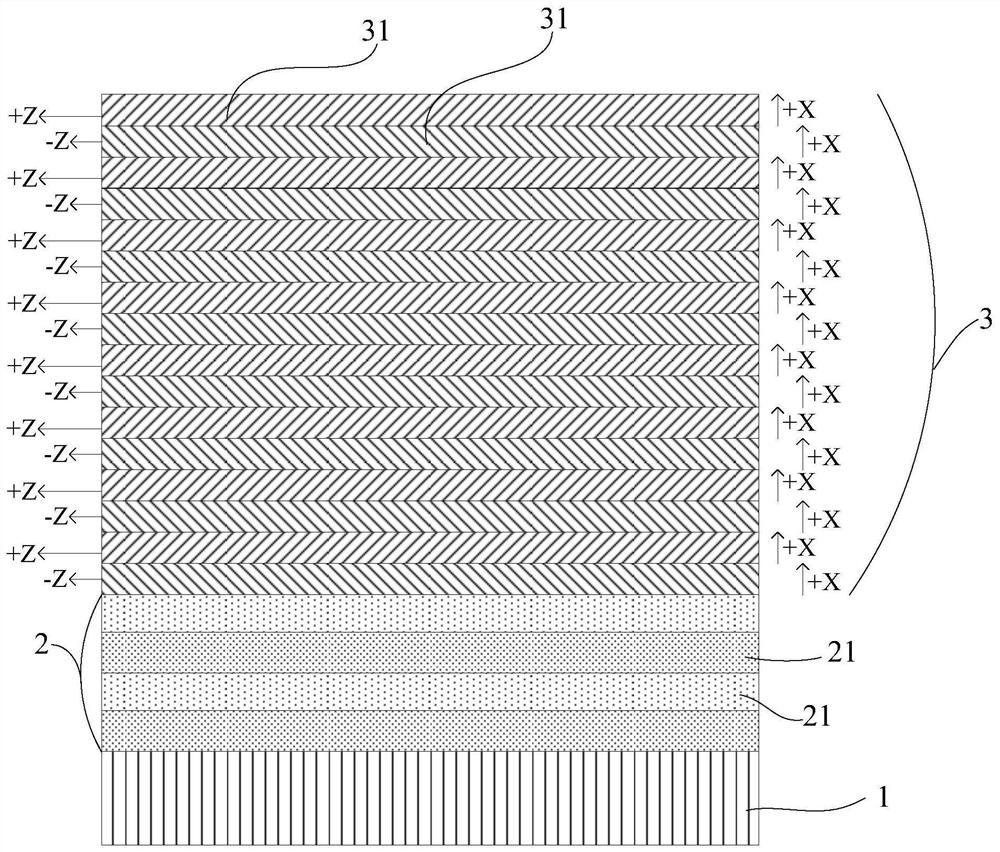

Embodiment 2

[0138] (1) The preparation is 4 inches, the thickness is 0.5 mm and has a single crystal silicon substrate wafer having a smooth surface, and after cleaning silicon substrate, the thermal oxidation method is used in the single crystal silicon substrate crystal circle process. 2 μm silica layer, wherein the silica surface roughness is less than 0.5 nm;

[0139] (2) The preparation of X-cracked x-cut is a lithium tissue wafer (for ease of description, "the first crystal circle", the large cutting direction is + z-axis direction, and there is from the large cutting direction as the -Z-axis direction) , Use ion implantation method, from -X face ion ions (HE + ) Inject the first wafer, HE + The injection energy is 20 keV, the dose is 1 × 10 17 IONS / cm 2 , The first wafer is formed to form a thin film layer, the separation layer, and the remaining material layer three-layer structure;

[0140] (3) When a plasma bonding method, the thin film layer of the first wafer-x-x surface after i...

Embodiment 3

[0148] (1) The first single crystal silicon substrate (for easy depicting, hereinafter referred to as "first substrate") is cleaned, and the first substrate is cleaned, and the first substrate is cleaned. A silica layer having a thickness of 2 μm is prepared by a thermoxing method in the process plane of the first substrate, wherein the silica surface roughness is less than 0.5 nm;

[0149] (2) The preparation of 4 inches of X-cut niobate wafers (for easy depicting, hereinafter referred to as "first wafer", the large cutting direction is + Z axis direction, away from the large cutting direction of -Z-axis direction), Using ion implantation, ion ions from -X face (HE + ) Inject the first wafer, HE + The injection energy is 1000 keV, the dose is 1 × 10 16 IONS / cm 2 , The first wafer is formed to form a thin film layer, the separation layer, and the remaining material layer three-layer structure;

[0150] (3) The thin film layer of the first wafer-x-x-x surface after plasma injecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com