A coating resistant to molten zinc corrosion and wear and its preparation method

A melting-resistant and coating technology, applied in stainless steel parts, molten zinc corrosion and wear-resistant coatings and its preparation field, to achieve the effects of simple preparation process, reduced raw material costs, and low site and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, 304 austenitic stainless steel is used as the base, the size is 15mm×10mm×2mm, and the base is sandblasted to prepare the enamel coating. The preparation process is as follows:

[0035] (1) Enamel glaze formula:

[0036] The formula of enamel glaze is (mass fraction): silicon dioxide 42%, aluminum oxide 15%, boron oxide 8%, calcium oxide 16%, sodium oxide 2%, lithium oxide 3%, sodium fluorosilicate 7% %, calcium fluoride 7%.

[0037] (2) Preparation of enamel micropowder:

[0038] The above raw materials are ball-milled and mixed evenly, heated and smelted at 1500°C for 1 hour, quenched with water to obtain enamel glaze particles with specific components, and enamel micropowder with a particle size of less than 10 μm is prepared by planetary ball milling.

[0039] (3) Preparation of enamel slurry:

[0040] The enamel emulsion was prepared according to 1 g of enamel powder: 10 ml of absolute ethanol, and a uniformly dispersed enamel slurry was obtain...

Embodiment 2

[0045] The difference from Example 1 is that the enamel glaze formula is changed to (mass fraction): silicon dioxide 35%, aluminum oxide 15%, boron oxide 10%, calcium oxide 15%, potassium oxide 2%, oxide Lithium 3%, sodium fluorosilicate 10%, calcium fluoride 10%; wherein, the total content of silicon dioxide and aluminum oxide is less than 53%.

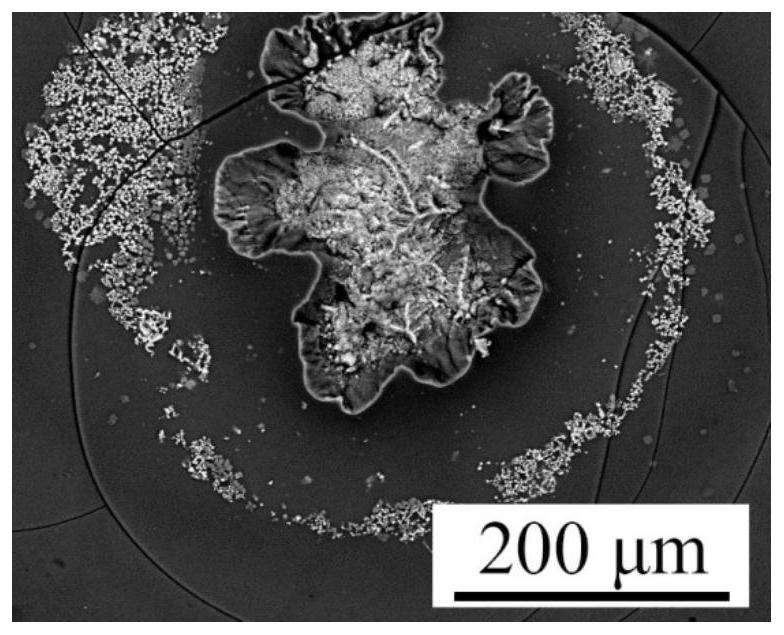

[0046] like figure 2 As shown in the figure, the surface of the prepared enamel coating has a macroscopic morphology, a large-scale glaze shrinkage area appears on the surface of the coating, and a ring-shaped crack is formed near the glaze shrinkage area.

Embodiment 3

[0048] The difference from the example is: (1) The enamel glaze formula is changed to (mass fraction): silicon dioxide 40%, aluminum oxide 15%, boron oxide 9%, calcium oxide 15%, sodium oxide 2% , Lithium oxide 2%, sodium fluorosilicate 10%, calcium fluoride 7%. (2) The sintering time of the enamel coating in a 1000 ℃ muffle furnace is 1 min.

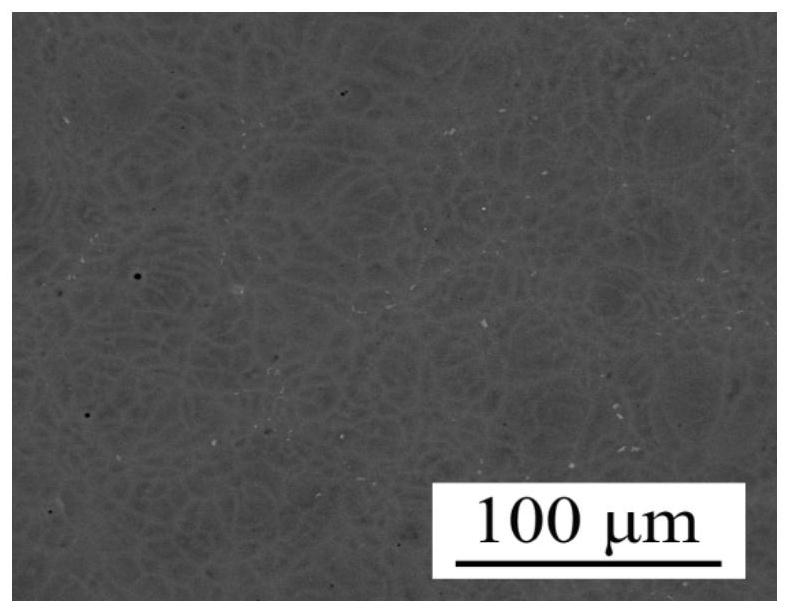

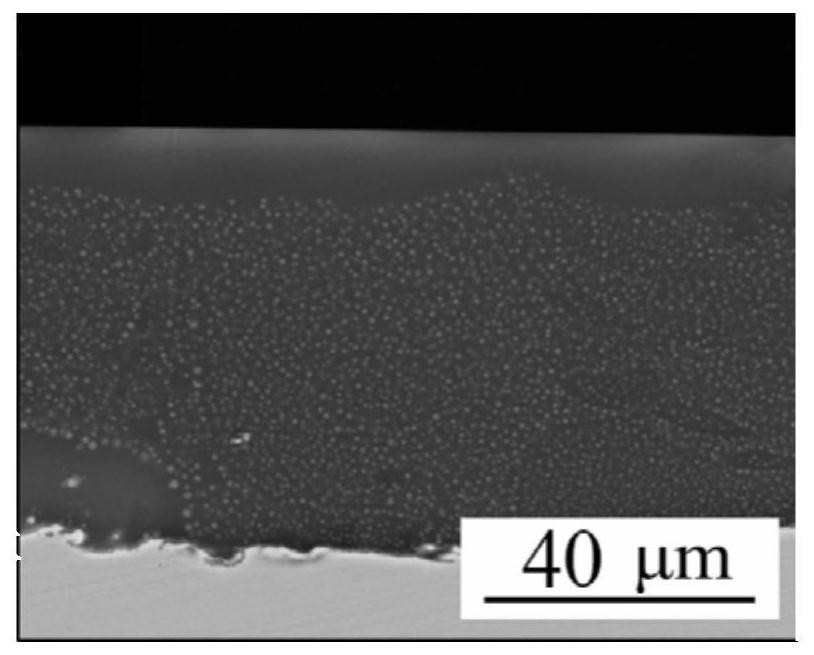

[0049] The surface morphology of the prepared enamel coating and the figure 1 similar, see image 3 , The enamel coating is firmly combined with the stainless steel substrate, and the interface has no microscopic defects such as holes and cracks. Inside the enamel, a large number of fine white bright crystals can be seen. Coating thickness ~ 100 μm. X-ray analysis showed that the main precipitation of fine white crystals in the coating was CaF. 2 . like Figure 4 As shown, the X-ray diffraction peaks of the enamel are all CaF except the steamed bread peak near 25° (corresponding to the glass phase in the enamel). 2 diffraction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com